PRONIL PROSEAL is a Thermoplastic Elastomer high-performance joint and crack sealing tape for construction joints, expansion (movement) joints and connection joints or cracks. It is a thin flexible sealing tape with extra-tough elastic strip providing considerable longitudinal and lateral extension. It is non-hazardous for users and provides long term resistance against bacterization. It is ideal for sealing and waterproofing expansion joints and over cracks subject to irregular and high movements. It is very easy to install. The use of thermal welding with the PROSEAL ensures secure and watertight joints.

Its advantages;

- Flexible & permanently elastic

- Highly versatile

- Good tensile properties

- Stable form and UV-resistant

- Heat weldable

- Easy to install

- Long term resistance to bacterizes

- Non-hazardous for users

Advertisement

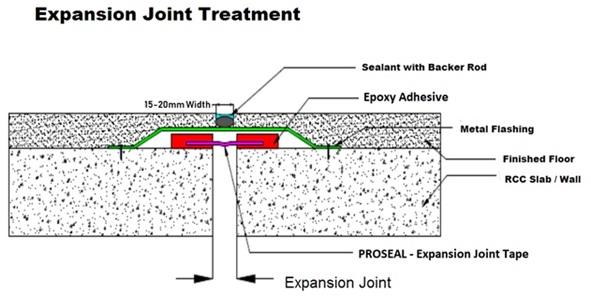

Method for Expansion Joint Treatment using PROSEAL

Expansion joint treatments using PROSEAL involve different steps to get the desired results. Each of them is explained below.

Step 1- Surface Preparation:

- Surfaces must be clean, sound and dry.

- Surfaces should be free from dust, oil, grease and other similar contaminants.

Step 2- Mixing – EPOXY ADHESIVE:

- Premix the “A” and “B” components separately.

- Then add the “B” component to the “A” component and mix them until the mixture is uniform in colour.

- For mixing, use a low-speed mechanical mixing device with a suitable mixing paddle.

Step 3- Application:

- EPOXY ADHESIVE is applied to the prepared substrate on both sides of the joint so that both sides of the PROSEAL are embedded into the EPOXY ADHESIVE on a width of at least 40mm. The layer thickness of EPOXY ADHESIVE should be approximately 2mm.

- The PROSEAL is then immediately embedded into the fresh EPOXY ADHESIVE and pressed using a hand roller or a similar suitable tool.

- Make sure that the PROSEAL has good contact with the EPOXY ADHESIVE everywhere.

- Then a second layer of EPOXY ADHESIVE is applied on top, so that the edges of PROSEAL are over coated on a width of minimum 40mm.

- Also apply EPOXY ADHESIVE at a width of at least 20mm, so that it covers the substrate next to the PROSEAL.

- The same is to be protected with Metal flashing by anchoring on one side only to accommodate the movement.

Step 4- Floor Finish

In the floor finishes, a groove of 15-20mm shall be maintained to facilitate the component movement and the groove will be sealed with a very high mechanical strength sealant which has very high resistance to chemical, UV rays, Resistant to Notches, Tension & tearing as shown in the diagram below.

Schematic Drawing of Expansion Joint Treatment Using PROSEAL