Underwater concreting is used for placing fresh concrete for offshore construction. It is used for sewerage, ducts, ports, bridges and marine works, in which concrete is to be placed underwater. It comes with a mix design capable of physical, mechanical and operational characteristics for operation in salt water and underwater. Underwater construction is constructed using various techniques in the smaller and larger water bodies. Crucial methods of underwater construction include caissons, cofferdams, driven piles and off-site building floats and lower. These methods are used to withstand the structures underwater.

Concrete mix design for underwater concreting requires the selection of suitable materials and proportioning to produce concrete for the specified application. Which mainly concentrates on the properties of workability/flow, compressive strength, and durability.

Performance requirements for Underwater Concrete

- Workability and self-compaction

- Cohesion against washout and segregation

- Low heat hydration

- Controlled set time

- High compressive strength

Materials For Underwater Concrete

- Coarse aggregates

- Fine aggregates (sand)

- Cement

- Anti-washout admixtures

Underwater concreting methods

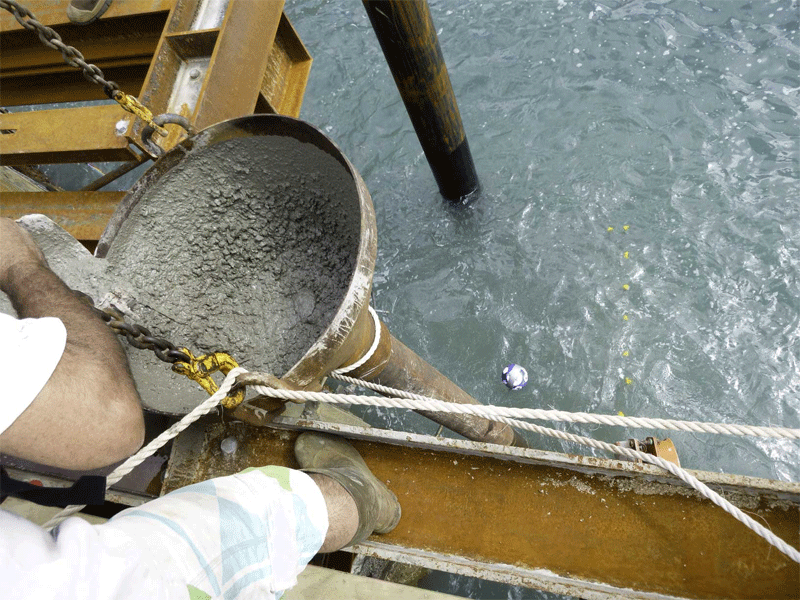

Tremie method

This method involves a tremie water-tight pipe having a funnel-shaped hopper at the upper end and a loose plug at the bottom end. The tremie is supported on a working platform above water level for concrete placing. The method involves;

- Placing tremie pipe to the concrete placement point

- After the tremie pipe reaches desired depth a funnel is fitted in the top end for concrete pouring

- The concrete with high slump is poured into the funnel until the tremie pipe is filled

- Tremie pipe is then lifted and then moved by winch and pulley and concrete gets discharged

- After discharge tremie pipe is again filled with and is repeated until concrete level comes above water level

Bucket Placing Method:

This method allows concrete at considerable depths. The dump buckets are usually fitted with drop-bottom or bottom-roller gates that open freely outward when tripped. The method involves;

- The concrete is deposited under water by a bottom opening bucket

- The buckets usually are fitted with a bottom roller or drop bottom gates

- The bucket is filled with concrete and its top covered with gunny sack and lowered slowly

- It is lowered by a crane up to the bottom surface of the concrete and then opened either by a suitable arrangement from the top or by a diver

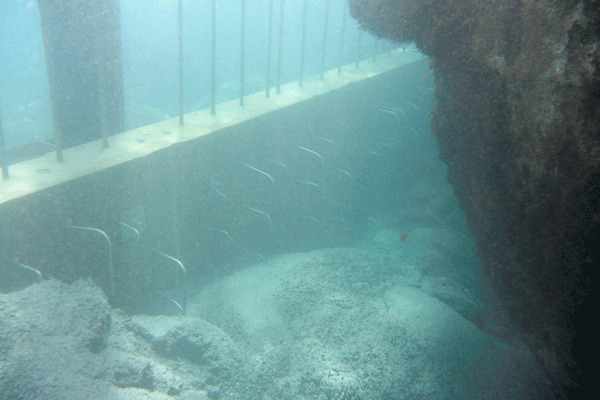

Pre-Packed Concrete or Grouting Method

The method consists of placing the coarse aggregate only in the forms and thoroughly compacting it to form a prepacked mass. This mass is then grouted with the cement mortar of the required proportions. The method involves;

- Placing round cages are made of mesh and steel bars, to the full height to be concreted

- Cages are laid vertically over the full area to be concreted

- After depositing the aggregate, the cement sand grout and water/cement ratio is prepared in a mechanical mixer.

- The prepared grout is sent downpipe

- As the grouting proceeds, the pipe is raised

- After this, the pipe may be withdrawn from this cage and placed into the next cage

- The procedure is repeated till all the cages are grouted up to this level

Placing in bags Method

This method uses gunny bags that are partially filled with concrete in such a way that they can readily be accommodated on which they are placed. The method involves;

- Filing of gunny sacks with concrete

- Tying them in such a way to be accommodated in a profile of the surface on which they are placed

- The filled bags are lowered into the water and placed carefully

Other underwater concreting methods;

Apart from the above-given methods, a few other methods are also used as per project requirements.

Hydro Valve Method

This method is using pipes to do the concreting. In this method when concrete is poured, it moves under the pressure of gravity.

Pneumatic Value Method

Pneumatic valves connected at the end of the pipe control the movement of the concrete. They can operate from outside to control the movement of the concrete.

Tilting Pallet Barge

This method is useful for shallow underwater applications. In this method, the concrete is poured in thin layers. Along the deck of the barge, a tilting pallet is constructed upon which concrete is spread uniformly

Preplaced Aggregate Concrete

It is used where pouring ordinary concrete is difficult or improbable. It includes placing aggregate in the forms then injecting concrete into the bottom and filling the forms to the top.

Conclusion

Underwater concrete is designed to enhance constructability and performance in water environments. Using the underwater concrete method, we can minimize interruption to plant operation and result in high savings. Underwater concreting has developed dramatically in recent years so that the mix can be proportioned to ensure high fluidity as well as high resistance to washout and segregation. This process can be successfully carried out and high-quality concrete can be produced if sufficient attention is paid to the concrete mix design and the production method applied. In this article, we have discussed different underwater concrete placing methods, in an upcoming series of articles we will highlight different types of materials used for underwater concrete.

Analysis of underwater concreting methods

Performance requirements for Underwater Concrete

Materials For Underwater Concrete

Underwater concreting methods

Tremie method

Bucket Placing Method

Pre-Packed Concrete or Grouting Method

Placing in bags Method

Other underwater concreting methods