In the building industry, it has been seen that materials, which were being used about a century back, are still very popular. Variety of alternative building materials are available which provide better, efficient, durable and cost effective construction and also ensure judicious utilization of available limited resources with least possible degradation of environment.

Building materials and technologies have evolved through ages. Housing and building conditions reflect the living standards of a society. Stones, mud, thatch/leaves and timber represent the earliest building materials used for the construction of dwellings. Hardly any energy is spent in manufacturing and use of these natural materials for construction. Durability of the materials, directly derived from natural materials like soil, thatch/leaves, timber, etc. is questionable. Quest for durable building materials is an ongoing phenomenon ever since man started construction activity. Brick burning represents one of the earliest examples of using energy (other than animate energy) to manufacture durable building materials from the soil/earth. Firewood was the main source of energy for burning bricks. Use of metal products represents the next energy consuming manufactured material for the construction, after bricks. Then comes the manufacture of lime and lime-based products. Burnt bricks, metal products and lime are the manufactured materials (using external energy sources) commonly used for construction by our ancestors for a very long period of time.

INTRODUCTION

Discovery of natural inorganic binders like pozzolanic materials lead to the use of lime-pozzolan (LP) cement for construction purposes. Experience of using LP cement paved the way for the invention of Portland cement in 1824. Portland cement and steel brought revolutionary changes in the construction practices from early part of 20th century. Then plastics and plastic products entered the construction industry. Thus the new materials, which are available for use in construction, have many advantages over conventional materials being used presently.

The demand for building materials has been continuously rising with the increasing need for housing both in rural and urban areas. Commercial exploitation of traditional building materials by various industries has aggravated the situation. It has therefore necessary to think over this problem seriously and to provide some sustainable solution to make the alternative materials available to solve the housing problem. The government of India is committed to the cause of bringing about rapid and sustainable development in rural as well as urban areas.

Bricks, cement, steel, aluminium, plastic products, paints, polished stone, ceramic products, etc. are the commonly used materials of construction today. These materials are energy intensive and are transported over large distances before being used for construction. The following points require attention, regarding the use of modern building materials: Energy consumed in the manufacturing processes – energy intensity; Problems of long distance transportation; Natural resources and raw materials consumed; Recycling and safe disposal; Impact on environment, and Long-term sustainability.

Thus the issues related to energy expenditure, recycling, biodegradable, and environmental and sustainability with respect to future demand need to be addressed during the manufacture and use of any new building material.

ISSUES ON ENERGY, ENVIRONMENT, SUSTAINABLE CONSTRUCTION AND BUILDINGS

Indian construction industry is one of the largest in terms of economic expenditure, volume of raw materials/natural resources consumed, volume of materials and products manufactured, employment generated, environmental impacts, etc. Large variety of materials are manufactured and consumed in the construction industry. It has been estimated that 22% of greenhouse gas (GHG) emissions is contributed by the construction sector in India. There is an ever-increasing demand for building materials.

For example demand for houses has doubled in about two decades from 1980. Compounded growth rates of 2.5%, 5% and 5% has been assumed for bricks, steel and cement respectively to compute the projected demand. In case of brick-making activity, at present topsoil equivalent of 300 mm from 100,000 hectares (1000 sq. km) of fertile land, 22 × 106 tonne of coal and 10 × 106 tonnes of biomass are consumed annually. We have an arable land area of 1.62 × 106 sq. km comprising alluvial soils, black soil, red soil, laterite soil and desert soil. Alluvial, laterite and red soils are suitable for brick making. Area under the soils suitable for brick making may not exceed 50% of the arable land. Brick-making activity to meet the present and future demand can result in consuming the 300 mm depth fertile topsoil of arable land in about 90 years (assuming 2.5% compounded growth rate). Similarly the pressure on raw materials like limestone to manufacture cement and energy requirements to produce these materials has to be addressed.

Production of building materials has slowly and steadily moved from highly decentralized and labour-intensive methods and processes to centralized, machine-dependent industry mode. Centralized mode of production necessitates hauling of raw materials and distribution of finished materials over great distances. These activities again require expenditure of fossil fuels for transportation. Transportation of raw and finished building materials is another key issue that can contribute to cost of materials, increased energy requirements and environmental issues. Sustainability of the present mode of production, consumption and distribution of building materials and currently adopted construction practices is questionable.

NEED FOR SUSTAINABLE ALTERNATIVES

Steel, cement, glass, aluminium, plastics, bricks, etc. are energy-intensive materials, commonly used for building construction. Generally these materials are transported over great distances. Extensive use of these materials can drain the energy resources and adversely affect the environment. On the other hand, it is difficult to meet the ever-growing demand for buildings by adopting only energy efficient traditional materials (like mud, thatch, timber, etc.) and construction methods. Hence, there is a need for optimum utilization of available energy resources and raw materials to produce simple, energy efficient, environment friendly and sustainable building alternatives and techniques to satisfy the increasing demand for buildings. Some of the guiding principles in developing the sustainable alternative building technologies can be summarized as follows: Energy conservation; Minimize the use of high energy materials; Concern for environment, environment-friendly technologies; Minimize transportation and maximize the use of local materials and resources; Decentralized production and maximum use of local skills; Utilization of industrial and mine wastes for the production of building materials; Recycling of building wastes, and Use of renewable energy sources.

Building technologies manufactured by meeting these principles could become sustainable and facilitate sharing the resources especially energy resources more efficiently, causing minimum damage to the environment.

ALTERNATE BUILDING MATERIALS

A large number of viable alternative building technologies have been developed and disseminated over a period of 2.5 decades. Some of these building technologies are: Stabilized mud blocks, Steam cured blocks, Fine concrete blocks, Rammed earth blocks, Mud concrete blocks, Lime–Pozzolan cements, Soil-lime plaster, Composite mortars for masonry, Composite beam and panel roofs, Reinforced brickwork/tile-work roof, Ferro cement and Ferro concrete roofing systems, Unreinforced masonry vaults and domes, Ribbed slab construction, Filler slab roofs, Rammed earth foundations, Reinforced block-work lintels and precast Chejja, Solar passive cooling techniques and Containment reinforcement for earthquake-resistant masonry.

ADVANTAGES

Besides being eco-friendly, the other advantages of using these materials for construction are:

- Better functional efficiency.

- Cost effectiveness.

- Better durability.

- Ease of construction.

- Better finish.

- Minimum waste.

- Less maintenance cost.

- Minimum defects.

- Less energy intensive.

One of the major component of Eco-housing practices using ‘Alternate Building Materials’ is Sustainable Construction Practices.

ECO-FRIENDLY MATERIALS

“Products or services that have a lesser or reduced effect on human health and the environment when compared with competing products or services that serve the same purpose.”

The use of Eco-friendly Materials became a necessity because of the following reasons;

- Phenomenal growth in the construction industry that depends upon depletable sources.

- Production of building materials leads to irreversible environmental impacts

Features of Eco-friendly materials

- Renewable Source.

- Reuse of Waste product.

- Low Embodied Energy.

- Local Availability.

- Reduction in air, land and water pollution.

- Durability & Life span.

- Aids Energy Efficiency in buildings.

- Durability & Life span.

- Biodegradable.

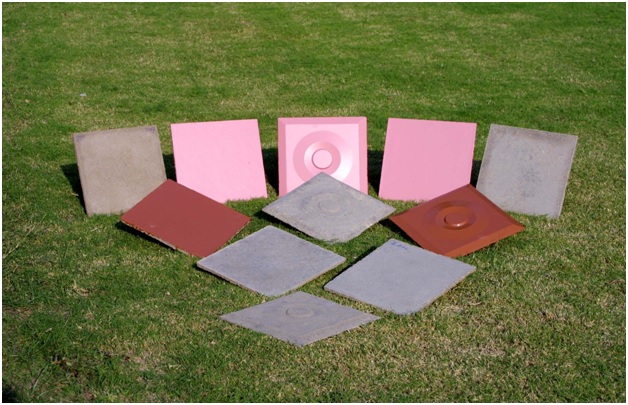

STABILIZED MUD BLOCKS

These are dense solid blocks compacted using a machine with a mixture of soil, sand, stabilizer (cement/lime) and water. After 28 days curing, the stabilized mud blocks (SMB) are used for wall construction. Two block sizes (305 × 143 × 100 mm and 230 × 190 × 100 mm) have been standardized. These blocks are 2.5 to 2.8 times bigger in volume when compared with locally available conventional burnt clay bricks. Compressive strength of the block greatly depends upon the soil composition, density of the block and percentage of stabilizer (cement/lime). Sandy soil with 7% cement can yield blocks having wet compressive strength of 3–4 MPa. High strength for the block can be obtained by increasing the quantity of stabilizer. Major advantages of SMB are: (a) energy efficient, do not require burning, 70% energy saving when compared to burnt bricks, (b) economical, 20–40% savings in cost when compared to brick masonry, (c) plastering can be eliminated, and (d) better block finish and aesthetically pleasing appearance.

BAGASSE – CEMENT BUILDING BOARDS

Numerous composites (Medium Density Reconstituted Boards) have already been developed using different natural and synthetic and man-made fibres in polymer matrix. Most of the boards are being used for replacing wood and other conventional reconstituted wood products. Some of these fibres have also been used for making high density fibre-board using cement (inorganic) as binder. The development is aimed to develop building boards and door shutter using Bagasse fibre. Building board is suitable for partitioning, panelling etc.

The developed product and process are prototype and laboratory level respectively. The physical-mechanical behaviour of the developed building board (prototype) passes most of the requirements of general purposes high density board and is cost effective too.

ARHAR STALK – CEMENT BOARD

Composites have great potential in replacing wood in building industry, but their development is associated with problems related to their processing, production and performance. The work carried out is intended to explore the possibilities of using fibrous biomass such as Arhar Stalks, Groundnut Shells etc. for the production of composite materials. Composite panels developed using Arhar Stalks meet the requirements of ISO, BS, and BIS specifications. The output of this article will help utilize fibrous biomass and preserve environment due to conservation of wood in building and construction industry.

COIR – CNSL BOARD

The Coir-CNSL Board is a wood alternative which can be used for surfacing, door and window shutters, partitioning, false ceiling, panelling, furniture, cabinets, packaging etc. It is a single layer flat pressed class Medium Density Fiber (MDF) Board. It has low water absorption, negligible change in dimensions due to water absorption, workable with normal wood working tools, paintable, pre-laminable, nail able and screw able, passes IS-3087. The board is eco-friendly and can replace wood or re-constituted wood by 100%.

Salient features of Coir-CNSL Board are as under;

- both the starting materials i.e. coconut fibre and cashew nut shell liquid are available substantially in coastal areas and are renewable agro-wastes.

- Technology is developed at pilot level and ready for transfer.

- The technology and product both are patented.

- The Technology is techno-economically viable as per pre-estimates.

LIGHTWEIGHT SANDWICH PANELS

The cellulosic refuse of paper industries are rich in small fibres and can be used to make value added product, which can be used for acoustics, thermal insulation and false ceiling purposes in buildings. The laboratory scale developed technology yielded a light-weight sandwich panel which is very much suitable for above mentioned purposes. These developed panels have their end applications in partitioning, panelling, thermal insulation and false ceiling with its unique aesthetics. The technology as well as product has been patented. The estimated economic viable capacity is 2 tonnes per day and most suitable for paper industries as a downstream process.

FINE CONCRETE BLOCKS

The concept and process is similar to the one employed for SMB production except that instead of soil, some fines are added to the mix. Fines like fly ash, polished stone waste, etc. are mixed with either sand or stone quarry dust, along with cement and water. The mixture is then compacted into blocks using a machine (manual or mechanized) and then cured for 28 days. Fines (like fly ash, polished stone waste, etc.) in the range of 20–25% by weight of sand can result in a good grading for the mixture and with 6–7% cement good quality block with wet strength > 3 MPa can be achieved. In addition to fines, about 10% red loamy soil addition can result in good natural mud colour for the block. The major advantage of fine concrete block is the utilization of waste products like fly ash, polished stone waste, mine wastes, etc. which otherwise cause pollution and environmental degradation.

STEAM CURED BLOCKS

A mixture of lime, industrial waste products like fly ash or expansive soils like black cotton soil and sand can be compacted into a high-density block. Lime reacts with fly ash/clay minerals forming water insoluble bonds imparting strength to the block. These reactions are slow at ambient temperatures (~ 30°C) and hence steam curing for about 10 h at 80°C can accelerate these reactions leading to high strength for the block.

The process involves:

- mixing of raw materials like lime, cement, fly ash or black cotton soil, sand and water in a mixer,

- converting the mixture into a dense block using soil block press,

- Stacking the blocks in a steam chamber and steam curing for 10–12 h.

Blocks of any convenient size can be manufactured. Compressive strength of the block depends upon the composition of the mix, density of the block and percentage of stabilizer (cement/lime). A combination like 25% fly ash, 6% lime and 2% cement can yield blocks having wet compressive strength of > 6 MPa. This kind of strength will be sufficient to construct 3–4 storey load-bearing buildings with spans in the range of 3–4 m. Blocks of higher strength can be easily achieved by adjusting the mix proportions. It should be noted here that the block quality is much superior when compared to local burnt bricks and SMB. Advantages of using these blocks are: (I) Ideal process for a small-scale or cottage industry, (ii) utilization of industrial waste products like fly ash and problematic soils like black cotton soil and high clay soils, (iii) energy efficient and environment friendly, and (iv) higher strength for the blocks.

Causes of Poor Acceptability of Alternative Building Materials

- Lack of knowledge about new materials.

- Non-inclusion in various National codes and specifications.

- In-appropriate environment for research and development.

- Non-availability of proper forum for promoting new materials.

- Ineffective and improper publicity.

- Unawareness among users.

- Poor competition among new material manufacturers.

- Higher price structure of new materials.

- Lower emphasis on research on eco-friendly materials.

- Negative attitude of engineers/ architects towards non-scheduled items.

- Lower confidence on quality.

- Negligible technological thrust for wider acceptance and adoption.

CONCLUSION

Alternative eco-friendly building materials and technologies at various levels will not only reduce the cost of construction but will also ensure no depreciation of world’s natural wealth. Now there is a need to put in organized efforts in the direction of using eco-friendly materials by replacing traditional materials. It is desired a positive role to be played by various government agencies, leading engineers and technologists, major users and entrepreneurs to bring sustainable development process in construction industry.

About Author

The author is the Managing Director at Skanda Group of Constructions. He is an experienced Civil Engineer with a demonstrated history of working in the construction industry. He is skilled in AutoCAD, Construction, Management, Concrete, and Structural Analysis.