Every year several parts of India is badly affected by several flash floods and landslides of bewildering variety. These floods landslides cause not only recurring losses of human life’s but also recurring economic losses worth billions of rupees.

The driving forces/pressures for flooding and landslides are of natural, manmade and combination of factors which interact in complex ways. Once instability is introduced, the hill slopes often become chronically prone to landslides. The problem of landslides is aggravated during the monsoon season due to (i) enhanced pore water pressure, (ii) increased weight of the rock mass and (iii) reduced frictional forces. There could be various reasons for such events but the main reason seems to be the inherent geology of the Himalayas and heavy rainfall. Torrential rains, generally called cloudbursts, or extreme rainfall are frequent events in the region.

Human activities on slopes such as: Construction done without proper engineering and geological inputs, Improper farming practices, Indiscriminate removal of vegetation cover and deforestation, etc. These activities may cause an increase in slope gradient or significant change in surface and groundwater regimes adding to the instability of slopes.

There is the possibility that several natural factors occur simultaneously. In some cases, one hazard triggers another. For example, an earthquake may trigger a landslide, which in turn may dam a valley causing upstream flooding and subsequent dam burst. This will lead to flooding in lower catchment areas. However we cannot fight with nature but with some technical help we can minimize the losses. There are several engineering techniques available to stabilize the soil slope to resist landslides and hence avoid disasters. These are retaining walls, piles, steel reinforcement, high strength steel tendons , grouting , shotcrete, guniting, nailing and geo synthetic reinforcement etc. For finalizing the best technique for stabilizing the soil, numbers of factors are considered like slope of accessibility of site, soil to be retained, purpose of stabilization, time, cost and capacity of reinforcement material etc.

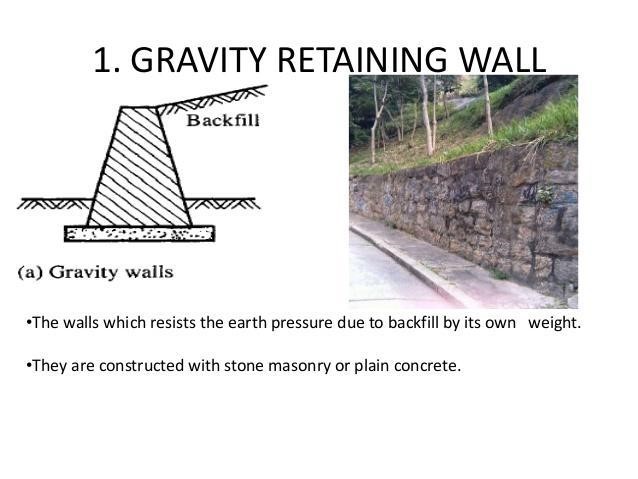

1. Retaining Walls: It is the most common technology to be used to retain soil through construction of retaining walls. Retaining walls are designed to resist lateral forces imposed by soil movement and water pressure. Based on the retained material movement forward and downward due to gravity ,there are several types of retaining walls i.e. gravity, cantilever and anchored.

- Gravity Walls :- Gravity walls rely on its weight for stability and are mainly made of Masonry units, mortar less stone and Concrete. For this purpose, the mass of the structure must be sufficient to develop enough frictional resistance to sliding, and the base or footing of the structure must be wide enough to develop sufficient momentum to resist overturning earth forces.

- Cantilever Retaining Walls :- These walls are generally built with Reinforced Cement Concrete. Cantilever walls are the taller retaining walls having uniform thickness and are tied to a footing. Properly engineered cantilever walls hold back sufficient amounts of soil. These walls cantilever loads to a large, structural footing, converting horizontal pressures from behind the wall to vertical pressures on the ground below .

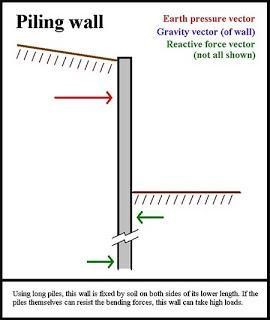

- Sheet Piling Retaining Walls:-Sheet pile retaining walls are usually used in soft soil and tight spaces. Sheet pile walls are made out of steel, vinyl or wood planks which are driven into the ground. The statistics of the walls include one-third portion above the ground and the rest (two-third) below ground level. A cable or a rod is used as a tie-back anchor to the walls. The rods are placed at a distance and tied to the back of the walls.

Sheet Piling Retaining Walls

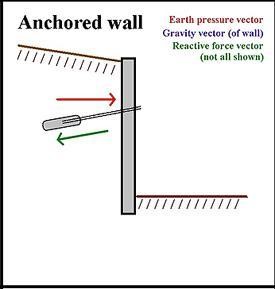

- Anchored retaining walls:-An anchored retaining wall can be constructed in any of the aforementioned styles but also includes additional strength using cables or other stays anchored in the rock or soil behind it. Usually driven into the material with boring, anchors are then expanded at the end of the cable, either by mechanical means or often by injecting pressurized concrete, which expands to form a bulb in the soil. Technically complex, this method is very useful where high loads are expected, or where the wall itself has to be slender and would otherwise be too weak.

Anchored retaining walls

- Bored pile retaining walls:-Bored pile retaining walls are built by assembling a sequence of bored piles, proceeded by excavating away the excess soil. Depending on the project, the bored pile retaining wall may include a series of earth anchors, reinforcing beams, soil improvement operations and shotcrete reinforcement layer. This construction technique tends to be employed in scenarios where sheet piling is a valid construction solution, but where the vibration or noise levels generated by a pile driver are not acceptable

Bored pile retaining walls

- Gabions:-Gabions are cages, cylinders, or boxes filled with soil or sand that are used in civil engineering and road walls particularly in hilly regions. For dams or foundation construction, cylindrical metal structures are used. Gabions are multi-celled, welded wire or rectangular wire mesh boxes, which are then rockfilled, and used for construction of erosion control structures and to stabilize steep slopes.

Gabions

2. Other Soil Retaining Techniques:- There are several other latest technologies available for soil retention. Few of them we will discuss here.

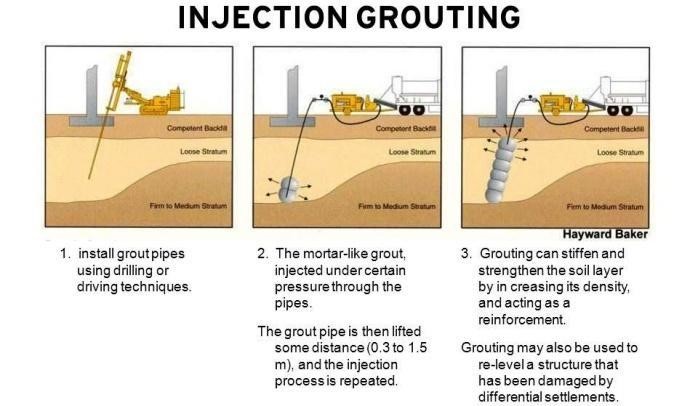

- Grouting:-Grouting is a cement, silicate, or acrylamide based slurry, viscose enough to be poured or injected into soil and thereby fill, seal, or compact the surrounding soil. Grouting is done through pressure injection of this slurry in holes drilled into fissured, jointed, permeable rocks and compressible soils to reduce their permeability and increase their strength. The type and amount of grout that is needed in a stabilization of slope is generally based upon grain size distribution, density, water content, and chemistry of the soil, as well as desired function of the grout. Grouting is often viewed as a versatile method of ground improvement for application in difficult soil and rock conditions.

Grouting

- Guniting (dry process):-The first technique of spraying concrete under pressure and high velocity by using a spray – gun developed in the US. The use of guns gave the name guniting. The guniting process is a trademark given for shotcrete process carried out with the dry mix. This process can also be known as dry-mix Shotcreting. It uses smaller size aggregate in the range of 10 mm or so. Final outcome is less strong product. High-skilled labor who knows to properly control and operate the nozzle so that a good mix is sprayed out reducing maximum rebound. Recommended for Small Quantity of Work.

Guniting (dry process)

- Shotcrete (wet process):- The technique of spraying concrete that came after guniting in the 1930s. This was conducted by using a nozzle spray. The mix can be dry or wet. The shotcrete process can be done with dry or wet mix and hence can be called as dry-mix shotcreting and wet mix Shotcreting. Maximum size of aggregates is 1 inch for the wet process of shotcrete. As the wet process will involve premixing of all the ingredients of the mix before pumping through the gun, a better quality of the product is obtained, unlike Gunite.

Shotcrete (wet process)

- Steel reinforcement:- Steel reinforcement members in the form of rock bolts, cable bolts, resin-grouted thread bars, or rock dowels are used to tie the rock mass together to increase its stability. Whereas rock bolts are commonly used to reinforce the surface or near-surface rock of the excavation, rock anchors are used for supporting deep seated instability modes in which sliding or separation on a discontinuity is possible. Three common types of ground inclusions are ground anchors, soil nails and rock bolts.

- Rock anchor:- Rock anchors are tendons which are placed in competent rock or soil to control displacements and provide vertical and lateral support for engineered structures and natural slopes. The primary function of rock anchors is to modify the normal and shear forces acting on the sliding planes. These anchors may be fully grouted and untensioned, or anchored at the end and tensioned.

Rock anchor

- Rock Bolts :-Rock bolts are used for reinforcement of rock slope and strengthening closely jointed or highly fissured rocks in cut slopes. A general rule for rock-bolt spacing is that the distance between faceplates should be approximately equal to three times the average spacing of the planes of weakness in the rock mass and the bolt length should be twice the bolt spacing. Rock bolts generally have heads that expand following installation and are classified according to their method of anchorage: expansion, wedge and grouted.

Rock Bolts

- Rock Dowels :-Grouted rock dowels consist of steel reinforcing bars (rebar) that are cemented into boreholes. These bars may or may not be subjected to post-tensioning. Untensioned dowels, therefore, do not provide any additional normal force across the failure plane. However, they provide additional shearing resistance across the potential failure surface plane. Rock dowels are commonly used to provide support for steeply dipping, slabby rock formations.

Rock Dowels

- Soil Nailing:- It is a soil reinforcement technique that places closely spaced metal bars or rods into soil to increase the strength of the soil mass by resisting tensile, shear, and bending stresses imposed by slope movements. Soil nails are either installed in drilled bore holes or secured with grout, or they are driven into the ground. The soil nails are generally attached to concrete facing located at the surface of the structure. The function of the facing is to prevent erosion of the surface material surrounding the soil nails, rather than providing structural support. This is a method of in situ reinforcement utilising passive inclusions that get mobilized in case slope movement occurs. It can be used to retain excavations and stabilize slopes by creating in situ reinforced soil retaining structures.

Soil Nailing

- Geosynthetic Reinforcement:- Geosynthetics are porous, flexible, man-made fabrics which act to reinforce and increase the stability of structures such as earth fills, and thereby allow steeper cut slopes and less grading in hillside terrain. Geosynthetics of various tensile strengths are used for a variety of stability problems, with a common use being reinforcement of unpaved roads constructed on weak soils. Geosynthetics and Geosynthetics – related materials are generally classified on the basis of their manufacturing process. Geosynthetics can be knitted, woven, non-woven or composite.

Geosynthetics are classified into the following:

- Geotextiles: These are permeable textiles—woven or non-woven synthetic polymers. Woven fabrics consist of two threads (warp and weft) combined systematically by making them cross each other perpendicularly. Threads could be multi-filaments or thick mono filaments, or tape threads. Multi-filament threads are made of polyester and polyamide; polypropylene and polyethylene are used to make tape threads. Non-woven fabrics consist of randomly placed short fibres (60 to 150 mm) or continuous filaments.

Geotextiles

- Geogrids: These are relatively stiff net-like materials with large open spaces between the ribs that make up the structure. They can be used to reinforce aggregate layers in pavements and for construction of geo-cells for improvement of bearing capacity. Geogrids are formed by a regular network of tensile elements with apertures of sufficient size to interlock with surrounding fill material.

Geogrids

- Geomembrances: A continuous membrane – type liner composed of asphaltic, polymeric materials with sufficiently low permeability so as to control fluid migration. Geomembranes are low permeability geosynthetics used as fluid barriers.

Geomembrances

- Geocomposites: These are various combinations of geotextiles, geogrids, geomembranes and/or other materials to serve all the primary functions with better performance.

Geocomposites

Conclusion

It’s important to note that different locations may require specific solutions based on the geological conditions and local factors. Therefore, it is advisable to consult with geotechnical engineers and experts to develop site-specific strategies to minimize landslides and flash floods effectively.

About author

The author is General Manager OF M P Construction Co. with nearly 14+ years of experience in construction projects & leveraging standalone expertise in making timely decisions that positively impact project success. His expertise is Project Execution & Project Management for Various Civil Projects Railways/Metro/Bridges/ Building/Highway/Airports etc. He is currently handling Chennai Metro Rail project, Western Dedicated Freight Corridor and Railway Line Doubling work of Dound-Kalburgi Section in Solapur Division of Central, Railway-Maharas