Ethylene Propylene Diene Monomer is a very important topic that should be analysed. This thermo set membrane is compound from rubber polymer and is often referred to as rubber roofing. The American Society for Testing and material (ASTM) classifies this material as an M Class Polymer. Ethylene and propylene derived from oil and natural gas, are organic building blocks of EPDM. When combined with diene to from the basic rubber matrix, the result is long-chain hydrocarbon with a backbone of saturated molecules and pendant double bonds. The Practical translation is ethylene, propylene and diene combine to forma large molecule that is very stable when exposed to sunlight, heat, ozone (UV) and moisture.

EPDM (Ethylene Propylene Dimonomer) became the seal of choice with the leading roof fastener manufacturers. This terpolymer elastomer is particularly well suited for sealing washers due to its resistance to water, chlorinated water, dilute acids, alkaline, ozone and oxidizing chemicals. It has a negligible absorption rate, is not susceptible to swelling, and can withstand temperatures up to 100°C.

At REALM we recommend that consumers ensure that the washer they purchase complies with industry standards and supports the life and integrity of the roofing system.

The right balance of hardness, tear strength and compression performance determines how well a cut washer assembles, compresses and resists the tearing affects of swarf, and keeps the screw sealed throughout its life on the roof.

Washer Integrity and Exposure to Heat

Washers from materials other than EPDM will quickly breakdown on the roof as temperatures climb in the heat of the day. Research shows that on a 23°C (73°F) day a metal roof temperature can climb to 85°C (185°F).

BUT AREN’T ALL WASHERS THE SAME? An Expensive Assumption!

Because washers are small and relatively inexpensive, their importance in a roofing project is sometimes overlooked. However, a poor quality washer can result in enormous costs if it is badly designed or made of inferior material.

The EPDM seal can be inseparably bonded to washers of galvanized carbon steel, aluminum or stainless steel, or loose. Both provide a leak free and long lasting seal.

“With 4.5 Fasteners per square metre of roofing sheet, washers play a significant role in any roofing project.”

Leading Consultants recommend the used of EPDM sealing washers with low in carbon black. Adaptability feature allows it to be applied to virtually any roof surface: Flat, Spherical, Curved or slanted.

The range of employment and durability of EPDM elastomeric seals is as follows:

| Temperature resistance | -40°C to 100° C |

| Tensile strength | Good |

| Impact elasticity | Good |

| Abrasion resistance | Good to Very Good |

| Residual compression set | Very Good |

| Flame resistance | Low |

| Water resistance | Very Good |

| Acid resistance | Good to Very good |

| Alkali resistance | Very Good |

| Ozone resistance | Good to Very good |

| Weathering resistance | Very Good |

| Contact stains | None |

| Migration stains | None |

| Animal and vegetable oils | Very Good |

| Ageing in sunlight | Very Good |

| Ageing in heat | Very Good |

| Ultraviolet resistance | Very Good |

“It is important to realise that high heat affects tear strength.”

SEALING CRITERIA

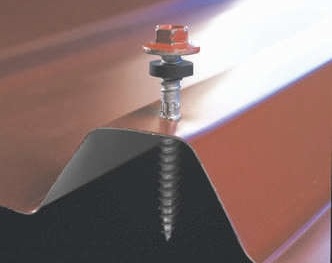

DRIVE FASTENER TO CORRECT DEPTH

- Provide visible marker of over-driving

- Reduce likelihood of stripping

SEAL THE SCREW

- Around shank & head

- Against roof material

METAL ON METAL ABRASION

- Provide cushion between metal surfaces

THERMAL CYCLIC LOADING

- Ease of movement for thermal expansion & contraction

The Roofix screws offer weatherproof fastenings here moisture or condensation is a factor. The integrated washer/head design seals the hole to SCREW prevent moisture from dripping into the fastener threads, reducing corrosive build-up. As added protection against corrosion, all Roofix screws come standard with Rustshield coating. The torque ABRASION control and adjustment of the Electric screwdrivers help ensure that the optimal seal is applied.

CUT WASHERS

CHECK THE BENEFITS!

- Only EPDM – No Neoprene Superior quality EPDM for reliable external performance

- UV and Ozone Resistance Formulated for maximum life span in harsh environments

- Non-conductive To guard against bi-metallic corrosion

METAL BONDED WASHERS

Four Sealing Points for Extra Protection

Each washer is designed to seal in 4 locations. This seals both the roof and the fastener in a way that other flat-punched washers cannot achieve.

| Description | Fastener Gauge | Diameter(mm) | Colour |

| A16-12/14 | 12/14 | 16 | Black |

| A19-12/14 | 12/14 | 19 | Black |

| A25-12/14 | 12/14 | 25 | Black |

POLYCARBONATE WASHERS (Product from DEKS Australia)

Typical Applications Include

| Description | To suit Fastener | Dia.XThikness (mm) | Colour |

POLYCARB for use in polycarbonate roofing

| 22mm | 10/12# | 22×8 | Grey |

| 25mm | 12# | 25×9 | Grey |

DekSEAL for use with a presses metal washer on type roofing (Cyclonic Purpose)

| Big | 12# | 35×5 | Black |

| Small | 12# | 29×6 | Black/Grey |

High Quality EPDM Dekcut™ Washers

Consistent Quality and Performance-that’s Dekcut™

CHECK THE BENEFITS!

- Only EPDM – No Neoprene Superior quality EPDM for reliable external performance

- Minimise Downtime Toleranced and controlled to suit automatic assembly

- Designed for Fast Assembly Fluted or smooth bore for maximum thread grip

- UV and Ozone Resistance Formulated for maximum life span in harsh environments

- Non-conductive To guard against bi-metallic corrosion

Easy hand or machine assembly

Offering both consistency and longevity, Dekcut™ washers come in two styles: fluted and smooth. While both are suited to automatic assembly, Dekcut™ fluted washers are particularly suitable for hand assembly. The fluted design ensures that they are quick to fit to fasteners but stay in place during transportation.

Dekcut™ Washers – Smooth

For maximum thread interface

Dekcut™ Washers – 4-Flute

For ease of assembly on standard fasteners

Dekcut™ Washers – 5-Flute

For ease of assembly on standard and oversized fasteners

Dekcut™ Washers – 6-Flute

For ease of assembly on oversized fasteners

Washer diagrams not to scale

- Need a quote for a special part? Call the DEKS R&D team.

- Dimensions given are nominal and subject to manufacturing tolerances

DEKS® is recognised as a world class manufacturer and designer of EPDM washers and has supplied washers globally for more than 30 years.

The DEKS® 20 year warranty is your assurance of a product that is designed to perform and made to last. Don’t risk your reputation on anything less – always choose DEKS®.

Author: Hitesh Parmar, MD, REALM INTERMEDIATES PVT LTD.