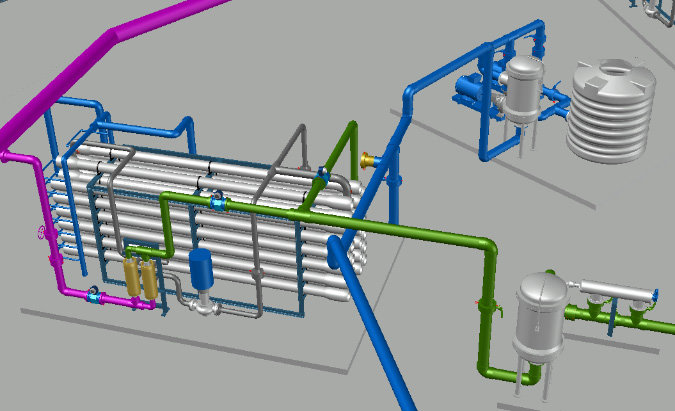

Membrane filtration method is used for separating components that are dissolved or suspended particles in a liquid. The process is a physical separation method described by the facility to separate molecules by their characteristics and different sizes. The membrane is a physical obstruction that, depending on its physical and/or chemical properties, allows certain compounds to pass through the membrane. So membrane filtration is a physical procedure for particle separation of particles by means of semi-permeable membranes. Membrane filtration is a rapidly expanding field in water treatment. There are many different types of filters available in a wide range of pore sizes and configurations. In addition, there are numerous possible applications for membrane filtration ranging from the removal of relatively large particulate material to the removal of dissolved compounds.

Membrane materials

Most membranes are synthetic organic polymers. Microfiltration and ultrafiltration membranes are often made from the same materials, but they are prepared under different membrane formation conditions so that different pore sizes are produced. Membranes can also be prepared from inorganic materials such as ceramics or metals. Ceramic membranes are microporous, thermally stable, chemically resistant, and often used for microfiltration. However, disadvantages such as high cost and mechanical fragility have hindered their widespread use. Metallic membranes are often made of stainless steel and can be very finely porous. Their main application is in gas separations, but they can also be used for water filtration at high temperatures or as membrane support.

Types of Membrane Filtration

Micron Filtration

The process removes dirt, debris, and even microscopic particles from water. The pore size of a filter cartridge is measured in microns. The smaller the micron rating, the finer the particulate removed. Which size micron filter you need depends on the size of the smallest particle that needs filtering from your water. The material of construction for micro filters surface depending on the application area means they may be made from plastic, textile fabric or stainless steel. Some new technology membranes are made of robust materials and large area format to provide excellent economy and extremely stable performance independent of variability in feed water.

Ultrafiltration

Ultrafiltration (UF) is a membrane filtration process similar to Reverse Osmosis, using hydrostatic pressure to force water through a semipermeable membrane. The pore size of the ultrafiltration membrane is usually 103 – 106 Daltons. Ultrafiltration (UF) is a pressure-driven barrier to suspended solids, bacteria, viruses, endotoxins and other pathogens to produce water with very high purity and low silt density. Ultrafiltration (UF) is a variety of membrane filtration in which hydrostatic pressure forces a liquid against a semi permeable membrane. Suspended solids and solutes of high molecular weight are retained, while water and low molecular weight solutes pass through the membrane. Ultrafiltration is not fundamentally different from reverse osmosis, microfiltration or nanofiltration, except in terms of the size of the molecules it retains.

Nanofiltration

Nanofiltration is a membrane filtration-based method that uses nanometer-sized through-pores that pass through the membrane. Nanofiltration membranes have pore sizes from 1-10 nanometers, smaller than that used in microfiltration and ultrafiltration, but just larger than that in reverse osmosis. Membranes used are predominantly created from polymer thin films. Materials that are commonly used include polyethylene terephthalate or metals such as aluminum. Nanofilters are commonly referred to as membrane softeners because they will commonly reject the double-positively charged hardness ions fairly well but cannot reject the single-positive charged soft ions like sodium & potassium.

Reverse osmosis

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property that is driven by chemical potential differences of the solvent, a thermodynamic parameter. Reverse osmosis can remove many types of dissolved and suspended chemical species as well as biological ones from water, and is used in both industrial processes and the production of potable water.

Membrane Filtration Uses in Wastewater Treatment

- Desalination of salt water to produce potable water remains the primary use of membrane filtration.

- Filtration of surface or groundwater under the direct influence of surface water can be accomplished using membranes with the largest pore sizes.

- As a pretreatment step in water treatment.

Conclusion

A membrane is a thin layer of semi-permeable material that separates substances when a driving force is applied across the membrane. Membrane processes are increasingly used for removal of bacteria, microorganisms, particulates, and natural organic material, which can impart color, tastes, and odors to water and react with disinfectants to form disinfection byproducts. Membranes are now being used in the newly emerging application of wastewater reuse, the fastest growing and potentially most promising membrane application in the water industry.