The Underwater Metro in Kolkata is not only a feat of modern engineering but also a testament to human ingenuity and innovation. This groundbreaking project connects two bustling cities, Howrah and Kolkata, via an underwater tunnel beneath the Hooghly River. It represents a significant milestone in India’s transportation infrastructure, showcasing the country’s capability to undertake ambitious projects that redefine urban connectivity.

The East-West Metro project, spanning a significant part of the city, includes an underwater stretch of 520 meters beneath the Hooghly River, positioning it alongside notable global counterparts such as London’s Underground and the Paris Metro. This achievement encapsulates years of meticulous planning, advanced engineering, and relentless work, overcoming geographical, technical, and logistical hurdles.

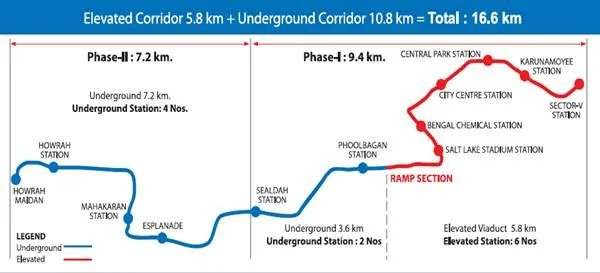

The underground ground is the biggest and deepest river tunnel in India spanning a length of 10.8 km, in India designed specifically for metro rail service. This tunnel is a part of the East West Metro Line (Line 2) of the Kolkata Metro and represents a significant expansion of the city’s metro rail network. It connects the Phoolbagan metro station in Kolkata with the Howrah Maidan metro station in Howrah, facilitating a crucial link across the Hooghly River.

Route and Connectivity:

The underwater metro route traverses beneath Kolkata, linking vital areas such as Howrah Maidan, Esplanade, Salt Lake Sector V, and BBD Bagh. This strategic connectivity enhances accessibility and mobility for residents, commuters, and tourists alike, fostering economic growth and development across the region. By seamlessly integrating with existing transportation networks, the underwater metro facilitates smoother transitions for passengers and reduces travel times between key destinations.

With 17 stations spread across 22 kilometers, including both elevated and underground stations, the underwater metro route offers comprehensive coverage of Kolkata’s urban landscape. Its integration with India’s largest commuter railway terminals, Howrah and Sealdah, ensures seamless intermodal connectivity for travelers, facilitating efficient commuting experiences. Moreover, the inclusion of stations in business districts and residential areas enhances accessibility and convenience for diverse user groups.

Project Genesis and Execution

The inception of the project dates back to 2010, with a vision to enhance Kolkata’s transportation infrastructure and provide a rapid, efficient means of crossing the river. The construction of the underwater segment was awarded to a joint venture between Afcons Infrastructure Limited and the Russian company Transtonnelstroy, known for its expertise in similar projects worldwide.

Different Methods and Technologies used for Construction

Constructing a tunnel under a river was a complex undertaking fraught with challenges, primarily centered around ensuring the tunnel’s stability and integrity throughout construction and its operational lifespan. To address these challenges, various techniques, technologies, and equipment were used to navigate through the geological strata beneath the river with precision. As construction progressed, concrete segments were installed to form the tunnel walls immediately, providing structural support and stability. This process demanded meticulous engineering calculations to effectively counterbalance the pressure exerted by the river’s water to prevent the riverbed above from collapsing. Different methods, equipments and technologies used for construction of the underground tunnel is discussed below.

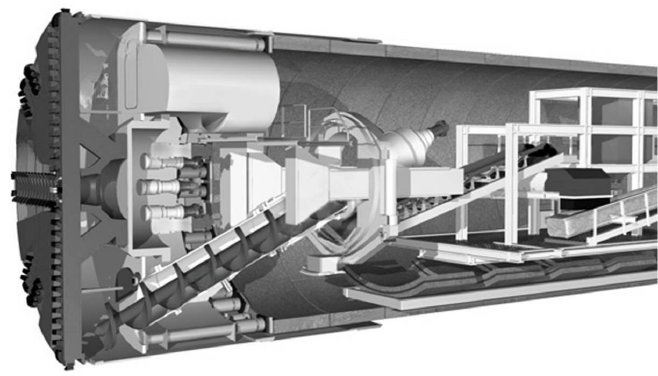

1. Tunnel Boring Machines (TBMs):

Kolkata’s underwater metro project faced unique challenges due to the soft soil conditions of the Hooghly River’s bed. Traditional excavation methods would have been impractical and risky. Therefore, the project opted for Tunnel Boring Machines (TBMs), which are massive, cylindrical machines equipped with rotating cutting heads. The project utilized two advanced Tunnel Boring Machines (TBMs) named Rachna and Prerna. These TBMs were specifically designed to bore through various types of soil and rock with minimal disturbance to the surrounding environment.

The advanced TBMs used in Kolkata’s project were equipped with cutting-edge technology, including real-time monitoring systems that allowed engineers to track the progress of tunneling operations and make adjustments as needed. Automated control mechanisms ensured precise alignment and smooth excavation, reducing the likelihood of errors or delays. Additionally, the TBMs’ precise navigation capabilities ensured that the tunnels were excavated according to the planned route, minimizing deviations and optimizing efficiency.

2. Hydrophilic Gaskets:

One of the important aspects of constructing an underwater tunnel is ensuring that it remains watertight. Any leakage could lead to flooding, structural damage, and safety hazards. To address this challenge, the Kolkata metro project incorporated hydrophilic gaskets into the tunnel construction. These gaskets are made of materials that swell upon contact with water, effectively sealing any gaps or cracks in the tunnel lining.

By expanding to fill voids, the gaskets create a watertight barrier that prevents water ingress, ensuring the long-term integrity and stability of the tunnel structure. This innovative solution not only provides protection against potential leaks but also reduces the need for costly and time-consuming maintenance in the future.

3. Earth Pressure Balance (EPB) Tunneling Techniques:

Soft soil conditions pose significant challenges for tunneling operations, particularly in underwater environments where the risk of ground settlement and collapse is heightened. To overcome these challenges, the Kolkata metro project employed Earth Pressure Balance (EPB) tunneling techniques. The technique involves carefully controlling the pressure exerted by the soil on the tunnel face to maintain stability and prevent deformation. This is achieved by adjusting parameters such as the rate of excavation, the pressure of the soil conditioning materials, and the rotation speed of the cutter head.

By carefully balancing these factors, engineers were able to ensure that the tunnel face remained stable throughout the excavation process, minimizing the risk of collapses or ground subsidence. Additionally, EPB tunneling helped mitigate the impact of construction activities on the surrounding environment, reducing the risk of damage to nearby structures or infrastructure.

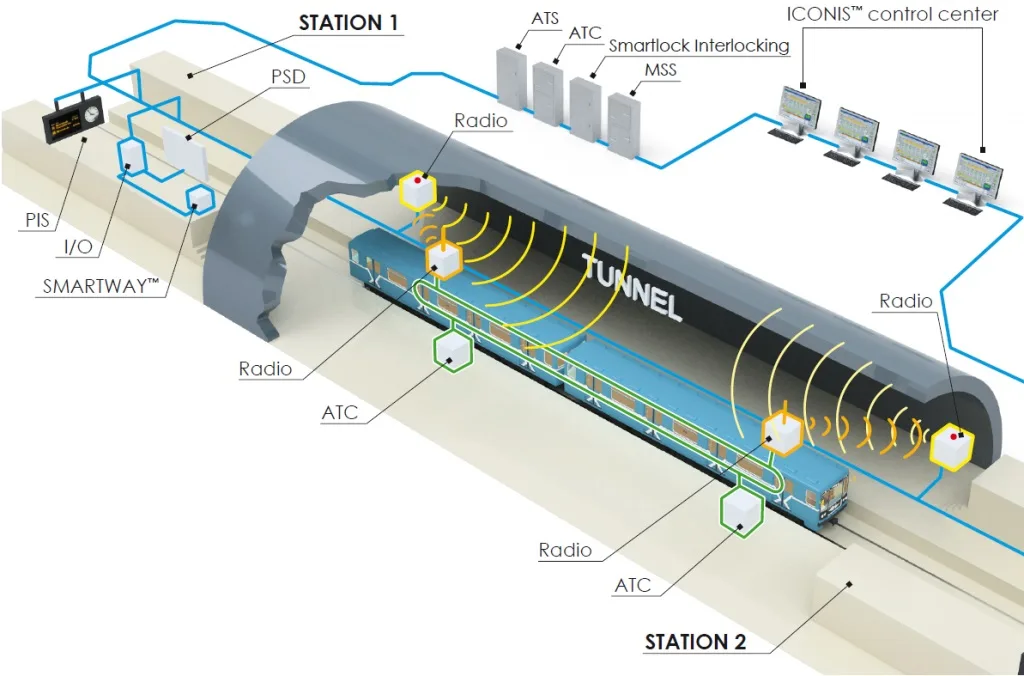

4. Communication-Based Train Control System:

The implementation of a Communication-Based Train Control (CBTC) system represents a significant advancement in metro rail technology. Unlike traditional signaling systems, which rely on fixed trackside equipment to control train movements, CBTC systems use wireless communication technology to transmit data between trains and the central control system. This allows for more precise monitoring and control of train operations, enabling features such as automatic speed regulation, real-time tracking, and enhanced safety protocols.

In the context of the Kolkata underwater metro project, CBTC technology played an important role in ensuring the safe and efficient operation of trains through the underwater tunnels. By providing continuous communication between trains and the control center, the system enabled rapid response to any emergencies or disturbances, minimizing the risk of accidents and ensuring passenger safety.

5. Underwater Aesthetics:

In addition to the technical innovations employed in the construction and operation of the underwater metro, the project also paid attention to aesthetic considerations to enhance the passenger experience. Illuminating the underwater tunnel section with blue lights not only serves a practical purpose by providing visibility but also creates a visually stunning ambiance that transforms the journey into a memorable experience.

The use of illuminated fish adds an element of whimsy and wonder, engaging passengers and turning the underwater metro into a unique attraction in its own right. By incorporating these aesthetic features, the project demonstrates a commitment to creating a comfortable and enjoyable commuting experience for passengers, reinforcing Kolkata’s reputation as a city at the forefront of urban innovation.

Challenges for construction of underground metro tunnel

Throughout the project’s lifecycle, various challenges tested the resilience and resourcefulness of the project team. From realigning sections of the route to navigating through densely populated urban areas, each obstacle was met with innovative solutions and collaborative efforts. These challenges includes;

1. Geological Conditions: Kolkata’s soft, alluvial soil and the presence of aquifers posed significant challenges during tunneling. The project team had to adapt construction techniques and implement ground treatment measures to stabilize the ground and mitigate the risk of ground settlement and collapse.

2. Heritage and Urban Constraints: Tunneling near densely populated areas and heritage structures required careful planning and coordination to minimize disruptions and prevent damage. Permissions from relevant authorities and temporary relocations of residents and shops were necessary to ensure the safety of surrounding infrastructure.

3. Safety Concerns: Ensuring the safety of passengers, workers, and surrounding infrastructure throughout the construction process was a primary concern. The project team implemented rigorous safety protocols and monitoring systems to prevent accidents and mitigate risks associated with tunneling and underground construction.

Conclusion

The inauguration of the underwater metro not only signifies a technological leap but also places Kolkata at the forefront of innovative urban transit solutions in India. It reflects the city’s historical significance as a hub for cultural and technological advancements. This project is a shining example of how technological innovation, when coupled with effective planning and execution, can overcome the complex challenges of modern infrastructure development, setting a precedent for future projects within India and beyond.