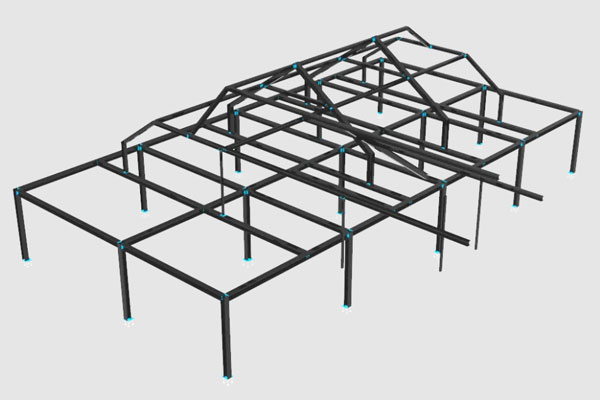

Structural steel framing refers to a building frame where the vertical and horizontal structural elements are formed by a system of structural steel beams and columns. It is made of a “skeleton frame” of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame.

Different types of structural steel framing for buildings include skeleton, wall bearing and long span framing systems. Each of them is discussed below.

Skeleton Steel Framing

Skeleton frame A skeleton frame is a framed structure often used for the construction of multi-story buildings. It incorporates a network, or system, of columns and connecting beams which support the building’s interior floors and exterior walls and carries all loads to the foundations. It is made from a series of columns and steel beams which are all connected. Around the structure’s perimeter, spandrel beams are installed to support masonry walls. To find the correct lengths, the distance between each column needs to be set by the structure’s requirements.

There are different types of components and steel connections that are used to connect steel beams to columns in skeleton frame structures. For connections between column and beams, there are a lot of components involved such as the use of metal brackets, gusset plates and haunches which help to distribute the induced stresses. Shims help in making line and elevation adjustments. Shelf angle brackets help in attaching the spandrel beam and column. For bolt and welded connections, flexible end plate, fin plate and double angle cleat are used.

Wall Bearing Steel Framing

Wall bearing steel framing involves the erection of masonry walls on the perimeter and interior of the building and the structural steel members are then anchored on the masonry walls using bearing and end steel plates and anchor bolts. The design and construction of the wall-bearing framing depend on the load intensity and the span distance between successive supports. While lower depth beams help to increase the clear headroom height of the building it also poses a requirement for the closer spacing of the columns and hence limits the clear floor space area.

In this type of framing system the building’s wall, exterior or interior is designed to support the roof/floor load. These rigid frames need to be strong enough to resist any additional horizontal load. The framing is suitable for the construction of lower structures. This is because the size of the bearing wall must be increased significantly to withstand considerable loads exerted in the case of multistory buildings.

Long Span Steel Framing

Long Span Steel Framing is used for wide spans with a large clearance requirement, where conventional beams and columns aren’t appropriate. A long span is a span that exceeds 12m. It helps to provide flexible floor space, column-free internal spaces, reduction in the on-site construction period, allows for installation of multiple services and mixed-use of spaces. It is typically used for large industrial buildings, auditoriums, theatres, exhibition spaces etc. This framing system is largely used on bigger projects that require taller arches and heavier loads.

Long span steel framing options can be categorized into different types

- Trusses – comes with the advantage of spanning long distances due to the greater depth they possess making them stiff against deflections. The types of trusses used for long-span construction include Pratt trusses, Warren Trusses, Fink Trusses, Scissors, Bow String and Vierendeel Trusses.

- Girders – deep steel beams which help to span long distances. The spanning length depends on the girder steel grade and the span depth ratio. Girders are installed in different ways there are stub girders that span longitudinally across the structures being connected to the main girders and the hybrid girders

- Arches – can be made as solid arches or open web arches, three-hinged, two hinged or fixed arches. These depend on the type of structural materials to be used, strength capacities, anchorage, building use, foundation type and the loading conditions.

- Rigid frames – designed to bear both bending moment and shear forces. They are designed as full continuous frames through the whole length and height in the absence of the hinges or pins in the crowns and mid-span.

Conclusion

We have discussed the different types of structural steel framing systems used when erecting a building. These are used for medium and high-rise, industrial, warehouse and commercial/ residential buildings. Steel frames are also extremely flexible, being able to bend without any cracks. This could be particularly useful in circumstances like earthquakes or heavy winds. Steel frame failure is generally a prolonged event. When selecting the frame go with the experienced steel frame fabricators.