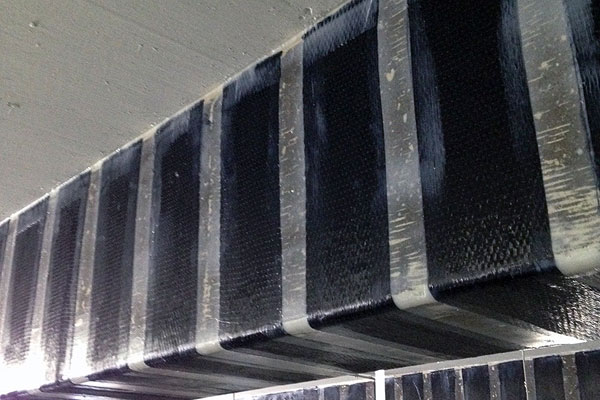

A structure may require restoration and retrofitting due to upgrading of design standards, increased safety requirements, change in its function, loads can increase or higher building standards become required and the structure must be made compliant. In such scenarios appropriate method and material is a prerequisite to regaining its structural strength. One such method is Carbon Fiber wrap technology. It uses carbon fiber fabrics on the surface of the concrete to form a composite that works in coordination with concrete to strengthen the component structure and improve its mechanical performance. The method can be used on nearly any type of structural member to harden and increase structural capacity and protect against uplift, progressive collapse, and spalling. The method provides solidarity to structures and ensures against further consumption and disintegration.

Advantages of Carbon Fiber Wrapping

The reinforcement technology of carbon-wrapped columns has the least interference to structural members. Effective use of carbon fiber reinforced concrete or polymers can significantly increase the life of the structure and minimize maintenance requirements. The columns wrapped in carbon fiber are corrosion resistant, so they are used for corrosion control and repair of reinforced concrete structures. Carbon fiber reinforced concrete and carbon wrapped columns are also widely used to strengthen concrete structures. Carbon fiber is one of these materials, which is usually used in combination with other materials to form a composite. The properties of carbon fiber, such as high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion makes them one of the most popular materials in civil engineering. Its advantages includes;

- Corrosion resistance

- Short construction period

- No maintenance required

- The increased flexural capacity of column, beam, and slabs

- Spall protection

- Hardening of the structural member without significantly increasing its size

- Adds strength to concrete

- Increases load carrying capacity

- Minimal change to structure’s shape and appearance

- Faster installation

- Protection from environmental degradation

Applications of Carbon Fiber Wrapping

Carbon Fiber Wrapping System works best for projects subject to progressive collapse and corrosion, including:

- Slabs

- Piers

- Timber Piles

- Docks

- Dams

- Bridges

- Beams

- Commercial piping

- Shaft foundations

- Pile foundations

- Seawalls

- Cement columns

- Pen Stocks

- Water Intake and Discharge Systems

Conclusion

Carbon Fiber wrapping provides significant strength to structures and protects against further corrosion and erosion. The impervious material will protect a structure from moisture intrusion and further corrosion. There are many reasons for strengthening a structure, such as decreased performance due to fatigue, a change of use, increased loading or required modifications. The carbon Fiber wrapping can be applied in single or multiple layers depending on the level of strengthening or increased structural capacity to be achieved. The selection of the right composite becomes pivotal in carbon wrapping, take the advice of the experts in this regard. In this article, we have discussed the advantages of carbon Fiber wrapping, in an upcoming series we will discuss its different applications.