Concrete structures deteriorate with time and deterioration is much faster in extreme environments associated with high humidity, chlorides and CO2 in the atmosphere. Ingress of moistures and deleterious substances such as chloride ions, CO2 and other chemicals take place through the pores of the concrete by the process of diffusion and initiates the corrosion of reinforcement and subsequently damaging the RC (Reinforced Concrete) structures.

Protection of RC structures by a suitable protective coating is a well-accepted method for increasing the service life in such an extreme environment. Without a protective coating the degradation of RC structures becomes very fast for corrosion of embedded steel reinforcement. This is where anti-carbonation coating comes. Anti-carbonation coatings are surface treatments that have a high resistance to carbon dioxide. They protect concrete from carbonation by acting as a carbon dioxide barrier. Anti-carbonation coatings are surface treatments that have a high resistance to carbon dioxide. They protect concrete from carbonation by acting as a carbon dioxide barrier. But prior to the application of coating, it is very important to study the failure pattern and consider other products for repair treatment.

Advantages of Anti- Carbonation Coatings

Anti-carbonation depends on the barrier property of a coating and also coatings permeability or resistance to diffusion to atmospheric CO2. Most of the anti-carbonation coatings are solvent based composition of acrylic solution polymer, properly selected & graded inert fillers, light fast pigments & additives.

The anti-carbonation coating is also formulated to protect reinforced concrete and other masonry cementitious substrate that is directly exposed to atmospheric conditions like UV radiation, high humidity, heavy rain, industrial pollution, & carbonation. It penetrates into the porous concrete substrate, producing an exterior masonry impermeable coating. Various types of Silicone enhanced, vinyl and polyurethane coatings are also very much suitable for anti-carbonation properties. The coatings of generic bases of polyethylene, epoxy, tar epoxy, chlorinated rubber, bituminous, cementitious, silicone and silicate are not suitable for anti-carbonation coatings. Some of its advantages are-

- These coatings are excellent barriers to penetration & attack of carbon dioxide, water, sulphates and chloride ions.

- The coating protects the structures from adverse marine and coastal environments.

- They provide excellent adhesion to substrate, with a high film build-up.

- They also provide excellent algae / fungal resistance.

- Since they are single components, straight way applied from the container, by brush, roller or spray application.

- They provide a tough, flexible & durable coating.

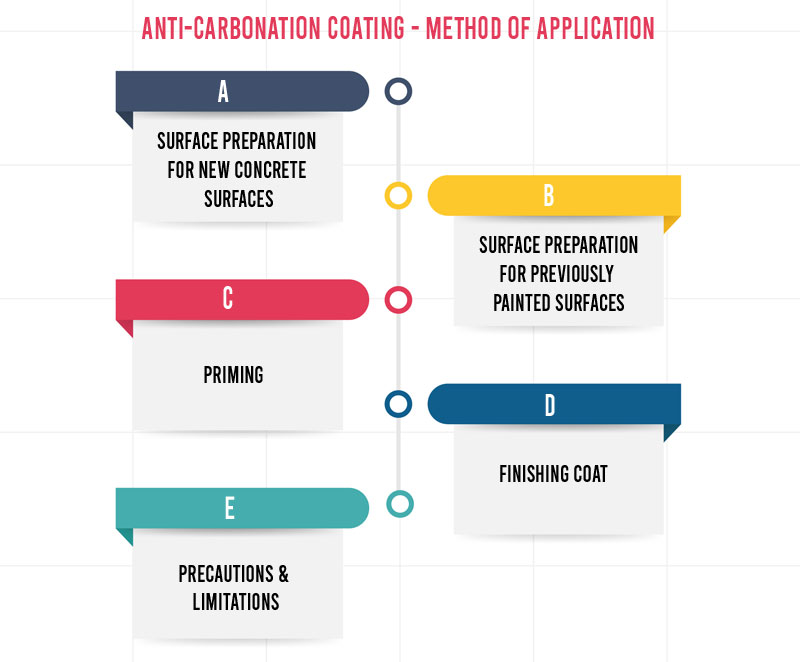

Anti-Carbonation Coating – Method of Application

A. Surface Preparation for New concrete surfaces

New concrete / plastered surfaces must be allowed to cure for at least 6-8 weeks before coating. Unless sufficient curing is done, entrapped moisture will exert pressure on the coating membrane. All surfaces must be clean, dry and free of loose material, oil grease; etc. Light grit blasting should be done in case of concrete surface ensures better cleaning & bonding. The concrete surface should be washed thoroughly with water to clean dirt & dust which may hamper decorative effect & bonding of the coating. Any previous growth of fungus & algae should be removed completely by vigorous wire brushing and cleaning with water. Treatment with proper biocide solution should also be done prior to the application to ensure complete removal of algae / fungal growth.

B. Surface Preparation for Previously Painted Surfaces

Alkyd paint if any should be sanded thoroughly to remove completely all loose particles. Mechanical methods are most suitable. Exterior surface previously coated with cement paint should be wire brushed and washed with water thoroughly and allowed to dry. Treatment for algae / fungal growth remains the same as new concrete surfaces. All cracks should be treated appropriately using elastomeric sealant or crack repair materials.

C. Priming

To produce better bonding & surface finish, primer should be applied by brush or spray, diluting in 2:1 proportion with mineral turpentine. It should be allowed to dry for 2-3 hours before application of the finishing coat.

D. Finishing Coat

Two neat coats of anti carbonation coating should be applied when the first coat is dry for 5-6 hrs.

E. Precautions & Limitations

Although a gap of 5-6 hours may be given between the two coats, in cold / humid climates, dry up time may be extended. The coating products should be stirred well before the use. Application should not be done when ambient temperature is below 10°C.

Applications of Anti – Carbonation Coatings

Anti carbonation is used as protective & decorative coating for bridges, flyovers, subways, underpass, parking garages, tunnels, chimneys, industrial structures, stadiums, and RCC water tanks. Also all concrete structures and cementitious exterior masonry plastered surfaces that are exposed to the extreme atmospheric conditions. Also all thin RCC structures having less cover such as facades, fins are other areas of application of anti-carbonation coating.

Conclusion

Carbonation of reinforced concrete and masonry is almost impossible to avoid and begins as soon as the substrate is exposed to the elements. The concrete reacts with the carbon dioxide in the atmosphere and leads to a loss of alkalinity and corrosion of the reinforced steel.Different anti-carbonation coatings help to combat this and allow your buildings to remain visually attractive whilst avoiding costly repair and maintenance work down the line.

Image Source: ind.sika.com, heritageinfra.com