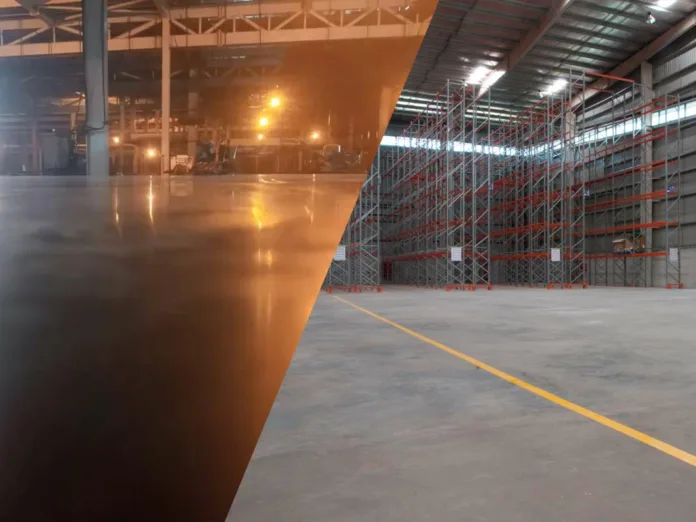

Different manufacturing facilities come with distinct requirements, each demanding specialised floor designs to meet their needs. Various range of facilities require different engineering and design, for example, flooring for automotive manufacturing facilities requires heavy machinery and MHE movements whereas solar manufacturing facilities require smooth movements of robotics and Automated Guided Vehicles (AGVs), each facility comes with different challenges.

Requirements of manufacturing facilities:

- Tailored designs for specific manufacturing types

- Sustain to Withstand machinery and equipment

- Resistance to chemical or process-related spills

- Easy maintenance for cleanliness and safety

- Consideration of load-bearing capacity

- Compliance with industry regulations and standards

Different design and engineering methods are required to construct the floors for the manufacturing facility. Avcon Technics is addressing these requirements based on their experience and array of successful projects over the years. For Manufacturing of Products and Project Execution the company was recently awarded the flooring contract for the upcoming greenfield project of solar panel manufacturing in Gujarat spanning 3,87,000 square metres.

What makes them unique?

- First flooring company with ISO 9001-2015 certification in Concrete Floor Design, Manufacturing of Products & Project Execution.

- More than 3 decades of experience in laying special engineered flooring for various manufacturing facilities that include solar manufacturing plants, textile manufacturing units, heavy-duty equipment facilities etc.

- The company tackles challenges with their innovative approach. They recently designed grade slab for Olympic-size track in Bhubaneswar, for X, Y, Z directions addressing challenges such as stringent surface tolerance, crack prevention, and joints opening applications.

The company’s services cater to various spectrums from light to heavy manufacturing facilities. Collaborating closely with clients, the company understands their manufacturing facilities requirements providing recommendations for suitable flooring types.

Design and Engineered floor services provided by Avcon Technics

- Engineering and floor design: detailed soil report analysis, site assessment, load-bearing capacity calculations, and placement of expansion joints.

- Detailed floor plans: sectional elevations machinery placement, specifying material thickness for production areas.

- Material selections: specialised epoxy coatings and anti-static flooring products etc. for manufacturing facilities

- Customised design and product: layout and requirements of production equipment, special coatings, texture, and finish.

- Floor laying: addressing load resistance and material handling equipment requirements adhering to industry standards.

The company has provided services for:

- Data Centres & Electronics Plant

- Textile & Process Unit

- Food & Beverages Facilities

- Pharmaceutical Plants

- Solar Manufacturing Plant

- Assembly lines in Automobile & Engineering

- Engineering Manufacturing area & Gangways

- Aerospace detonator handling facilities

- DOD, Military & Military ordinance areas

- Electronics manufacturing & testing facility and many more

With two state-of-the-art manufacturing facilities in Gujarat & Maharashtra, Their continual association with some of the biggest brands and repeat clientele are a testament to the company’s outstanding performance.

For more details;

Avcon Technics Private Limited

103-105, SHEETAL PLAZA, 499 MODEL COLONY, PUNE- 411016

Phone: +91 9325019411/ 9175935787

Email: sales@avcontechnics.co.in, marketing@avcontechnics.com

Website: www.avcontechnics.