Chemical grouting is used to strengthen or seal soil and rock by injecting a liquid grout material into the subsurface. The grout, typically a mixture of water, cement, and various additives, solidifies and forms a stable mass. This process is commonly used to improve soil stability, fill voids, stop leaks, and provide support to existing structures or foundations.

The chemical grouting process

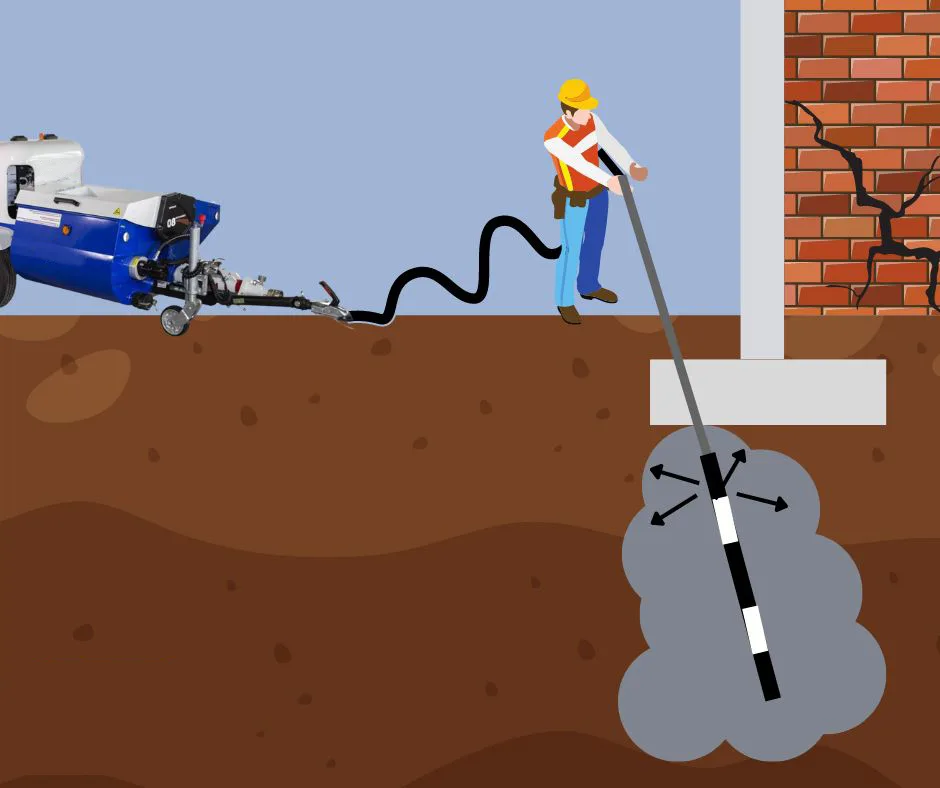

The chemical grouting process begins with drilling a hole into the ground and inserting a sleeve port pipe into the soil. Subsequently, chemical grout is injected under pressure through the ports. As the grout emerges, it fills gaps in the soil, expands, and solidifies. The newly-treated soil exhibits enhanced strength, stiffness, and reduced permeability.

Different types of chemical grouting

Polyurethane Grout: Polyurethane grout is a versatile material used in chemical grouting applications. Upon injection, it expands to fill voids and cavities in soil or rock, providing stabilisation and support. Its ability to permeate and solidify loose or unstable ground makes it effective for applications such as void filling, soil compaction, and foundation repair. Polyurethane grout is particularly beneficial in situations where traditional methods may be impractical, as it can adapt to various soil conditions and is resistant to water infiltration.

Acrylic Grout: Acrylic grout is used primarily for water control and soil stabilization. When injected into the ground, it forms a flexible and water-resistant barrier, making it effective in preventing water infiltration and providing stability to the surrounding soil. This type of grout is often used in construction projects where controlling water flow or stabilizing loose soil is essential. Its adaptability and durability make acrylic grout a valuable solution in scenarios where both water management and soil reinforcement are critical.

Silicate Grout: Silicate grout is known for its chemical reaction with soil particles, forming a solid mass that enhances soil stability. This type of grout is particularly useful in stabilizing loose or sandy soils where other methods might be less effective. Silicate grout provides a durable solution by chemically bonding with the soil, improving its load-bearing capacity. It is commonly used in geotechnical engineering and construction projects to address soil instability and prevent settlement issues.

Cementitious Grout: Comprising a mixture of cement, water, and additives, cementitious grout is employed for soil stabilization and void filling. This type of grout solidifies and strengthens the ground, offering increased load-bearing capacity. It is commonly used in tunneling, mining, and construction projects where the soil needs reinforcement. The versatility and simplicity of cementitious grout make it a popular choice for a wide range of applications, contributing to the stability and longevity of various structures.

Microfine Cement Grout: Microfine cement grout is a specialized material designed to penetrate fine fractures or porous soils, creating a solid mass. Its ability to reach and fill small spaces makes it effective in improving the overall stability of the ground. This type of grout is often used in soil improvement projects, such as underpinning foundations and stabilizing weak or compressible soils. The fine particles of microfine cement allow for enhanced penetration, resulting in a more uniform and thorough solidification of the targeted area.

Epoxy Grout: Epoxy grout is a high-strength bonding material used in chemical grouting for structural applications. It provides exceptional adhesion and durability, making it suitable for situations where long-term stability is crucial. Epoxy grout is commonly used in repairing cracks in concrete structures, anchoring bolts, and stabilizing soil in areas where traditional methods may not suffice. Its resistance to chemicals and ability to withstand heavy loads make it a preferred choice for critical structural reinforcement projects.

Sodium Silicate Grout: Sodium silicate grout reacts chemically with minerals in the soil to create a solid mass, offering effective soil stabilization. This grouting method is often used in situations where a durable and permeable solution is required. Sodium silicate grout is known for its ability to enhance the load-bearing capacity of the soil while allowing for water permeability. It is commonly employed in geotechnical engineering projects to address soil instability and provide long-lasting stability to the ground.

Different methods used for chemical grouting

Permeation Grouting: Permeation grouting involves injecting a low-viscosity grout into the soil to enhance its properties. This method is commonly employed for tasks such as void filling and improving the cohesion of soil. By permeating the soil, it addresses issues related to stability and structure, making it a suitable method for a variety of applications.

Compaction Grouting: Compaction grouting is a process of injecting a thick, mortar-like grout into the soil to displace and compact the surrounding materials. This method is particularly effective for lifting and stabilizing structures. By creating a denser soil matrix, compaction grouting helps enhance load-bearing capabilities and ensures the structural integrity of the treated area.

Curtain Grouting: Curtain grouting focuses on creating a grout curtain to either block water flow or stabilize soil. Applied along the perimeter of structures, this method is instrumental in preventing water infiltration. By forming a barrier with the injected grout, curtain grouting safeguards against potential issues arising from water seepage, contributing to the overall stability of the structure.

Jet Grouting: Jet grouting involves the high-pressure injection of grout through a nozzle into the soil, forming a soil-cement column. This method is commonly utilized for foundation support and soil mixing. By creating these cementitious columns, jet grouting provides improved structural support and stability, making it valuable for various construction and geotechnical applications.

Injection Wells: The injection wells method entails installing wells through which grout is directly injected into the soil at various depths. This approach is suitable for treating large areas or deep soil layers. Injection wells offer a versatile solution, allowing precise control over the grouting process and enabling efficient treatment of expansive soil volumes.

Soil Fracturing: Soil fracturing involves creating fractures in the soil by injecting grout under high pressure. This method enhances permeability and improves load-bearing capacity. By strategically inducing fractures, soil fracturing addresses issues related to compaction and stability, making it a valuable method for geotechnical applications.

Compaction Piles: Compaction piles are formed by drilling holes and filling them with grout to create compacted columns in the soil. This method increases load-bearing capacity and stabilizes the surrounding soil. Compaction piles are often employed in foundation work to ensure the integrity of structures by providing enhanced support and reducing settlement risks.

Void Filling: Void filling entails injecting grout into voids or gaps in the soil to provide support. This method is commonly used for tasks such as filling abandoned tunnels or mine shafts. By effectively filling voids, this method ensures the integrity of the surrounding soil and mitigates potential issues associated with empty spaces.

Pressure Grouting: Pressure grouting involves applying grout under pressure to fill cracks, voids, or improve soil structure. This method ensures thorough penetration and distribution of the grout, making it effective for tasks such as repairing and strengthening existing structures. Pressure grouting is a versatile method suitable for various applications, ranging from soil stabilization to structural repair.

Slab Jacking: Slab jacking is a method of lifting concrete slabs by injecting grout underneath. This method is commonly employed for leveling and repairing sunken or uneven slabs. By raising the slabs to their desired level, slab jacking addresses issues related to settlement and provides a cost-effective solution for restoring the functionality and aesthetics of concrete surfaces.

Application method of chemical grouting

1. Site Assessment:

– Conduct a thorough assessment of the site, including soil conditions, structure type, and the location of voids or instabilities.

2. Grout Selection:

– Choose the appropriate chemical grout based on the project requirements and soil characteristics.

3. Port Placement:

– Determine the optimal locations for injection ports based on the site assessment. Ports are typically spaced strategically to ensure even grout distribution.

4. Drilling Ports:

– Drill holes at the selected port locations using a suitable drilling method. The size and depth of the holes depend on the project specifications.

5. Port Installation:

– Insert injection ports into the drilled holes. These ports act as conduits for the grout to reach the targeted areas.

6. Pre-Grouting Testing:

– Conduct pre-grouting tests to assess the permeability and response of the soil. This helps in determining the appropriate injection pressure and grout flow rates.

7. Grout Mixing:

– Prepare the chemical grout according to the manufacturer’s instructions. Ensure proper mixing to achieve the desired consistency and properties.

8. Injection Process:

– Connect injection equipment to the ports and begin injecting the grout. Start with the port furthest from the injection source and gradually work towards it. Monitor pressure and flow rates.

9. Monitoring and Adjustments:

– Continuously monitor injection pressures, grout flow, and site conditions. Adjust injection rates and pressures as needed to optimize grout distribution.

10. Completion and Cleanup:

– Once the desired grout volume is injected and soil stabilization achieved, complete the injection process. Remove injection equipment and seal or plug the ports. Clean and restore the site as necessary.

11. Post-Grouting Inspection:

– Conduct post-grouting inspections to assess the effectiveness of the treatment. This may include post-grouting testing and monitoring for any signs of soil movement or structural changes.

It’s important to note that the specific steps may vary based on the chosen grouting method and project requirements.

Applications of chemical grouting

1. Soil Stabilization: Used to improve the strength and stability of soil, particularly in construction projects where weak or loose soil conditions exist.

2. Foundation Repair: Applied to stabilize and strengthen foundations of structures, preventing settlement or upheaval caused by soil movement.

3. Tunneling and Mining: Utilized to seal and stabilize tunnel and mine structures, preventing water ingress and enhancing overall stability.

4. Leak Sealing: Effective for sealing leaks in underground structures, such as basements, tunnels, and pipelines, by creating a watertight barrier.

5. Dams and Embankments: Employed to control seepage and prevent water from penetrating through dams, embankments, and other water-retaining structures.

6. Infrastructure Rehabilitation: Used in the repair and rehabilitation of aging or damaged structures, including bridges, retaining walls, and other civil engineering works.

7. Void Filling: Applied to fill underground voids, cavities, or abandoned mines, providing structural support and preventing subsidence.

8. Slope Stabilization: Used to reinforce slopes and prevent landslides by improving the cohesion and strength of the soil.

9. Groundwater Control: Employed to control and reduce groundwater flow in construction sites, especially in excavation projects.

10. Pipeline Support: Used to stabilize and support underground pipelines, preventing settlement and potential damage.

Conclusion

The chemical grouting method emerges as a versatile and effective solution in geotechnical engineering and construction projects. By injecting specialized chemical grouts into the soil, this method addresses issues such as ground stabilization, water control, and structural reinforcement. The method’s adaptability to various soil conditions, cost-effectiveness, and minimal disruption during application make it a preferred choice in addressing challenging subsurface conditions. As advancements in grouting technologies continue, the chemical grouting method is poised to play an increasingly pivotal role in enhancing the durability and longevity of civil engineering structures.

Image Source: rembco.com, ces-hire.com, bauerdamcontractors.com, kellerme.com