Grouting is a construction technique used to fill the gaps or voids between tiles, stones, or other materials to create a strong, durable, and visually appealing surface. It involves the application of a dense fluid material called grout, which is typically a mixture of cement, water, and sometimes sand or other additives. The primary purpose of grouting is to provide stability and support to the tiles or stones, preventing them from shifting or becoming loose. Additionally, grout helps to seal the gaps between tiles, making the surface more resistant to water penetration and reducing the risk of damage caused by moisture. The grouting process typically involves preparing the grout material, injecting it into the void or gap using specialized equipment such as grout pumps, and allowing it to cure or harden. The specific techniques and procedures may vary depending on the project requirements and the type of grouting being performed.

Advantages of grouting

Grouting offers several advantages in construction and civil engineering projects. Here are some of the key benefits of grouting:

1. Soil Stabilization: Grouting is often used to stabilize soil and improve its engineering properties. By injecting grout into the ground, it can fill voids, strengthen loose or weak soil, and increase the overall stability of the soil mass. This is particularly useful in construction projects where stable ground conditions are necessary for building foundations, tunnels, or retaining walls.

2. Structural Support: Grouting can provide structural support by filling voids or fractures in rocks, concrete structures, or masonry. The injected grout acts as a binding agent, strengthening the existing structure and preventing further deterioration. This is commonly employed in the repair and reinforcement of buildings, bridges, dams, and other civil engineering structures.

3. Water Control and Sealing: Grouting is an effective method for controlling water flow and sealing leaks. By injecting grout into cracks, joints, or porous materials, it forms a barrier that prevents water from infiltrating or escaping. This is extensively used in underground construction, such as tunnels, mines, and basements, as well as in the rehabilitation of dams and reservoirs.

4. Ground Improvement: Grouting can enhance the load-bearing capacity and improve the mechanical properties of the ground. It can densify loose soil, increase its shear strength, and reduce settlement. This is beneficial in areas with poor soil conditions or when the ground needs to be improved to support heavy loads, such as in the construction of highways, airports, or industrial facilities.

5. Leakage Mitigation: Grouting is an effective method for mitigating leaks in underground structures or containment systems. By injecting grout around pipelines, storage tanks, or underground storage facilities, it can seal potential leakage paths and prevent the release of hazardous substances or contaminants into the environment.

6. Minimizes Vibrations: In some cases, grouting can be used to minimize vibrations caused by dynamic loads or machinery. By injecting grout beneath vibrating structures, it increases their mass and damping properties, thereby reducing the transmission of vibrations to surrounding areas.

7. Foundation and underpinning: In cases where the soil beneath a structure is unstable or settling, grouting can be used to strengthen the soil or provide additional support. This technique is known as underpinning and is commonly used to stabilize foundations.

8. Versatility: Grouting can be applied to different materials and in various construction contexts. It is suitable for concrete, masonry, rock, and soil, making it a versatile technique used in a wide range of projects, including buildings, infrastructure, tunnels, and underground structures.

Types of grouting materials

Grouting involves the use of various materials depending on the specific application and desired outcomes. Here are different materials commonly used for grouting:

1. Cementitious Grouts: Cementitious grouts consist of a mixture of cement, water, and sometimes additives such as sand, fly ash, or admixtures. Portland cement is the most commonly used cementitious material. Cementitious grouts are known for their strength, durability, and ability to penetrate and fill voids effectively. They are used for a wide range of applications, including soil stabilization, structural repairs, sealing cracks, and creating watertight barriers.

2. Chemical Grouts: Chemical grouts are composed of chemicals that undergo a chemical reaction to solidify or expand upon injection. These grouts have low viscosity, allowing them to penetrate fine cracks and fissures. Chemical grouts include polyurethane grouts, acrylic grouts, and epoxy grouts. They are commonly used for crack injection, soil consolidation, and void filling.

3. Bentonite Grouts: Bentonite grouts utilize bentonite, a type of clay, as the main component. Bentonite grouts typically consist of a bentonite powder mixed with water to form a viscous slurry. Bentonite grouts have excellent sealing properties and are commonly used for groundwater control, such as in diaphragm walls, cutoff walls, or slurry trenches.

4. Resin Grouts: Resin grouts are composed of epoxy or polyurethane resins. These grouts are typically two-component systems that are mixed together just before injection. Resin grouts have low viscosity and can penetrate fine cracks and voids. They have high adhesive and compressive strength, making them suitable for structural repairs, crack injection, and soil stabilization.

5. Microfine Cement Grouts: Microfine cement grouts consist of very fine cement particles that can penetrate small fractures and fissures. These grouts are typically mixed with water to create a suspension that can be injected into the ground. Microfine cement grouts are used for soil injection, ground improvement, and rock grouting.

6. Silicate Grouts: Silicate grouts use sodium silicate or potassium silicate as the main component. These grouts react with calcium ions in the ground to form a solid gel-like material. Silicate grouts are used for soil stabilization, void filling, and improving ground conditions.

The selection of the grouting material depends on factors such as the project requirements, ground conditions,

Types of grouting methods

There are various grouting methods used in construction and geotechnical engineering to address specific needs and challenges. Here are different grouting methods commonly employed:

1. Injection Grouting: This method involves injecting grout under pressure into cracks, voids, or joints in structures or soil. It is typically used for sealing leaks, filling voids, or repairing damaged structures. Injection grouting can utilize different types of grout materials, such as cementitious grout, chemical grout, or resin-based grout, depending on the specific application.

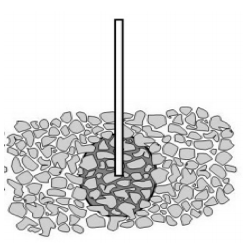

2. Permeation Grouting: Permeation grouting is used to improve the strength and stability of soil or rock formations. Low-viscosity grout is injected into the ground to fill voids and consolidate the surrounding material. The grout spreads through permeable zones, improving their engineering properties and reducing water permeability. Cementitious or chemical grouts are commonly employed in permeation grouting.

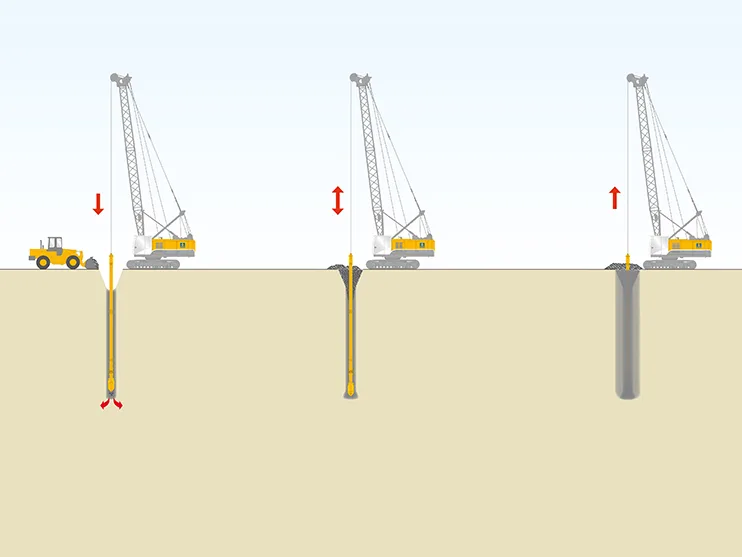

3. Compaction Grouting: Compaction grouting is a technique used to increase the bearing capacity of soils and reduce settlement. High-strength grout is injected under high pressure into the ground, displacing and compacting the surrounding soil. This method is effective for stabilizing loose or weak soils and is often used beneath structures or to mitigate sinkholes.

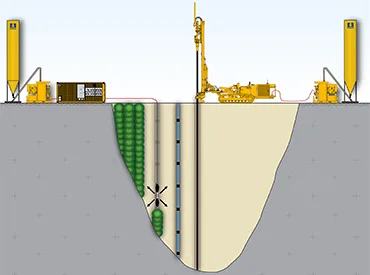

4. Curtain Grouting: Curtain grouting is used to create a watertight barrier in the ground, particularly in cases where groundwater control or cutoff walls are required. Grout is injected into the ground along a predetermined path to form a continuous impermeable barrier. Bentonite or cement-based grouts are commonly used for curtain grouting.

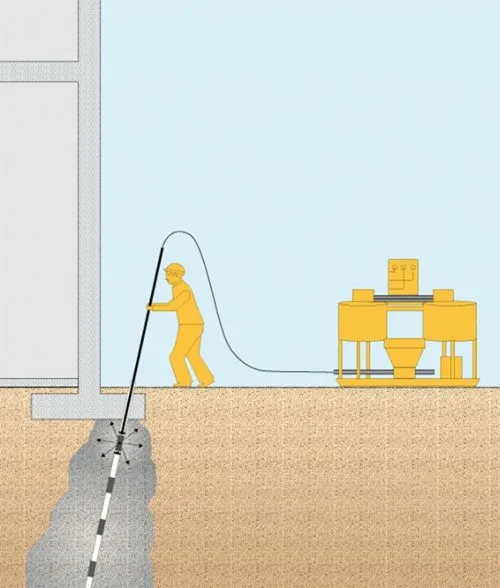

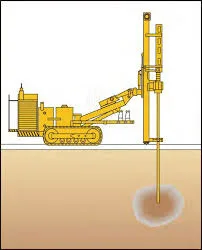

5. Jet Grouting: Jet grouting is a versatile method used to create structural elements in the ground or stabilize soil. It involves the high-pressure injection of a fluid grout into the ground while simultaneously rotating and withdrawing the injection rod. The grout mixes with the in-situ soil, forming columns or panels of soil-cement. Jet grouting is effective for creating cutoff walls, improving weak soils, or forming underground structural elements.

6. Compaction-Displacement Grouting: This method is a combination of compaction grouting and displacement grouting. High-pressure grout is injected into the ground to compact and stabilize the soil while simultaneously displacing it radially outward. This technique is used for improving loose or compressible soils, reducing settlement, and increasing load-bearing capacity.

Application method for grouting

Grouting method

Applying grout involves several steps to ensure a proper and successful application. Here is a general guide on how to apply grout:

1. Prepare the Surface: Ensure that the surface to be grouted is clean and free from debris, dust, or any loose material. Remove any old grout or caulking if necessary. If grouting tiles, make sure they are firmly set and in place.

2. Mix the Grout: Follow the manufacturer’s instructions to mix the grout material. Use the recommended ratio of grout to water or any specified additives. Mix the grout thoroughly until it reaches a smooth and consistent consistency. Allow the grout mixture to rest, if required, before applying.

3. Apply the Grout: Take a small amount of mixed grout onto a grout float or a rubber grout float. Hold the float at a 45-degree angle and spread the grout diagonally across the tile joints or the target area. Press the grout into the joints or gaps firmly, ensuring full coverage.

4. Pack the Joints: Use the edge of the float or a grout tool to pack the grout firmly into the joints. This helps eliminate air pockets and ensures a solid grout structure. Scrape off excess grout from the surface as you go.

5. Clean the Surface: After grouting a small area, wipe off the excess grout from the tile surface using a damp sponge or cloth. Rinse the sponge or cloth frequently and keep it clean. Be careful not to remove grout from the joints. Allow the grout to set for the recommended time.

6. Finishing Touches: Once the grout has set, use a clean, dry cloth to polish the tiles and remove any grout haze. Be gentle to avoid disturbing the grout in the joints. Check for any missed spots or low areas and touch up as necessary.

7. Cure and Seal: Allow the grout to cure for the recommended time specified by the manufacturer. This usually takes a few days. Afterward, consider applying a grout sealer or finisher to protect the grout from stains and moisture penetration. Follow the sealer manufacturer’s instructions for application and curing time.

Remember to always refer to the specific instructions provided by the grout manufacturer, as application methods and curing times can vary based on the grout type and brand.

Where grouting is used?

Grouting has various applications in construction, geotechnical engineering, and other industries. Here are some common applications of grouting:

1. Tile Installation: Grouting is extensively used in tile installations, such as ceramic, porcelain, or natural stone tiles. It fills the gaps between tiles, providing structural support, aesthetic appeal, and protection against moisture and dirt.

2. Concrete Repair: Grouting is used to repair cracks, voids, or damaged areas in concrete structures. It helps restore the structural integrity, improves durability, and prevents further deterioration.

3. Foundation Stabilization: Grouting is employed to stabilize foundations and underpin structures. It can be used to fill voids beneath foundations, increase load-bearing capacity, and mitigate settlement issues.

4. Soil Stabilization: Grouting techniques like compaction grouting, permeation grouting, or jet grouting are used to stabilize loose or weak soils. Grout is injected into the ground to densify the soil, improve stability, and reduce permeability.

5. Sealing and Waterproofing: Grouting is applied to seal joints, cracks, or gaps in various materials, including concrete, masonry, or rock. It prevents water infiltration, air leakage, or the passage of other substances.

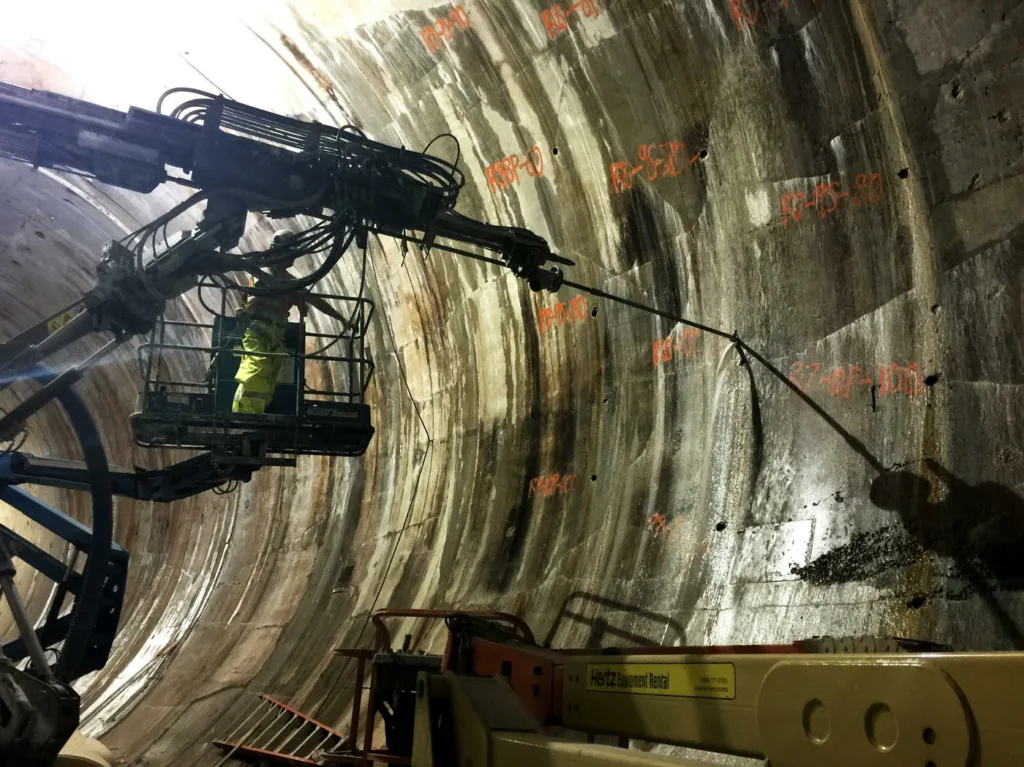

6. Tunnelling and Underground Construction: Grouting is utilised in tunneling projects to control water ingress, stabilize the ground, and prevent settlement. It can be used to create grout curtains, stabilize the tunnel face, or inject into the surrounding soil or rock.

7. Dam and Reservoir Construction: Grouting plays a crucial role in dam and reservoir construction to control seepage and maintain structural integrity. It is used to create cutoff walls, consolidate foundations, and address leakage issues.

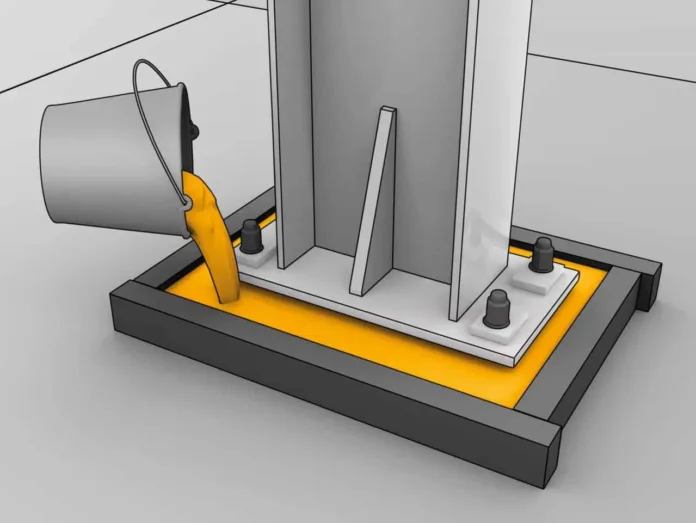

8. Anchoring and Doweling: Grouting is employed to anchor or dowel various elements, such as steel bars, rods, or bolts, into existing structures or substrates. It provides secure connections, enhances load transfer, and increases structural stability.

9. Jointing and Bonding: Grouting is used to fill joints, gaps, or interfaces between different components or materials. It ensures structural continuity, improves load transfer, and prevents the ingress of contaminants.

10. Geotechnical Applications: Grouting techniques are widely used in geotechnical engineering for ground improvement, slope stabilization, soil consolidation, or to create underground barriers. Different grouting methods are applied based on the specific project requirements.

Conclusion

Grouting encompasses a wide range of materials, methods, and applications that play a vital role in construction and geotechnical engineering. As construction and geotechnical engineering continue to evolve, the advancement of grouting materials, methods, and applications will drive innovation and open new possibilities for solving complex engineering challenges. Successful grouting requires expertise in material selection, method implementation, and quality control. Engaging experienced geotechnical engineers who understand the intricacies of grouting ensures optimal results and mini