Soil nailing is a ground stabilisation technique used to reinforce and strengthen existing ground. It can be used on either natural or excavated slopes. It involves drilling holes for steel bars to be inserted into a slope face which are then grouted in place. It is economical and also applicable in seismic zones. Increases shear strength of overall soil mass and can be used in wide soil types.

Advantages of soil nailing

- Suited for confined spaces with restricted access.

- Lesser environmental impact.

- Quick and easy to install.

- Uses fewer materials and shoring.

- Can be used on new constructions, temporary structures or on remodeling processes.

- Creates less noise and traffic obstructions.

- Less impact on nearby properties.

- Allows in-situ strengthening on existing slope surface with minimum excavation and backfilling.

- Can be used for strengthening of either natural slope, natural or manmade cut slopes

Design considerations of Soil Nailing

The design begins with an analysis of the site. The two most common limit states used in design are strength limit and service limit states. The strength limit state addresses potential failure mechanisms or collapse states. The service limit state addresses loss of service function resulting from excessive wall deformation.

Initial design considerations include wall layout (wall height and length), vertical and horizontal spacing, nail pattern on wall face, nail inclination, nail length and distribution, nail material and relevant ground properties.

After the initial design is completed, final design progresses where the the nail has to be tested for external and internal failure modes, seismic considerations and aesthetic qualities.

Drainage, frost penetration and external loads such as wind and hydrostatic forces also have to be determined and included in the final examination of the design.

Soil nailing methods

Drilled and grouted soil nailing methods – In this method holes are drilled on a sloped surface then nails with a diameter of 100-200mm spaced 1.5 meters on center are inserted on holes with grout. The nails are inserted in the pre-drilled holes and filled with grouting materials.

Driven Soil Nailing Method – It is used for temporary stabilization, it is fast. However, it does not provide corrosion protection to the steel or nails. Diameters of nails are around 19mm to 25mm spaced at 1 meter on centers.

Drilling Soil Nailing Method – In this method the hollow bars are used in this method, bars are drilled and grout is injected. This method is typically faster than driven nails.

Jet Grouted Soil Nailing Method – This method is used for eroding soil for creating holes in the soil surface, steel bars are installed in this hole and grout with concrete.

Launched Soil Nailing Method – This method involves nailing steel bars forced to the soil with a single shot using compression by an air mechanism. The diameter is around 38mm and its length is around 6m.

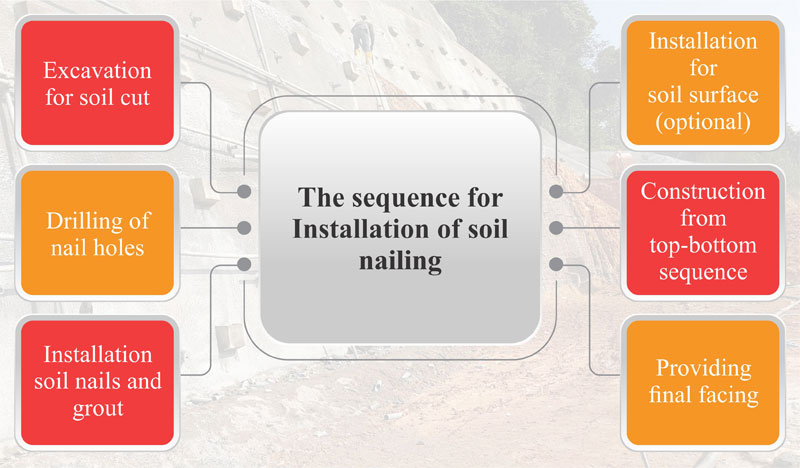

Installation of soil nailing

The process starts on drilling the soil and locating the nail and steel bar target points. And drilling is completed the nails must be inserted on holes. Then, the grout is applied into the soil to develop a structural member. Then reinforcement is placed on a soil surface to protect the soil.

Application of Soil Nailing

- Retaining walls

- Stabilization of ground slope

- Tunnel

- Roadway embankments and highway

- Bridge Abutments

- Excavation Shoring

Image source: soil-nailing.com, subsurfaceconstruction.com, dmidrilling.com, cforcivil.com, rocscience.com, 2020landtree.com, envirolok.com, maccaferri.com, externalworksindex.co.uk, subsurfaceconstruction.com, dishmaan.com