Rebar couplers are used in precast construction for facilitating strong and efficient connections between precast concrete elements. Their significance lies in expediting construction timelines by enabling rapid and precise assembly, reducing labour costs, and ensuring structural integrity. These essential components facilitate the connection of precast concrete elements, ensuring the seamless assembly of large structures like buildings, bridges, and parking garages. The importance of couplers lies in their ability to enhance structural stability by providing load transfer between adjacent precast members, thus eliminating the need for time-consuming and costly traditional cast-in-place joints.

Selecting the right product is of paramount importance as the correct choice of rebar coupler can greatly affect a structure’s load-bearing capacity, resistance to shear and tension forces, and ability to handle thermal movement and bending moments.The judicious selection of couplers not only ensures the efficient assembly of precast elements but also guarantees the safety and reliability of the entire structure, making it a critical decision in the construction process. Dextra couplers are known for their high-quality and reliability, ensuring a strong and durable connection between precast concrete components.

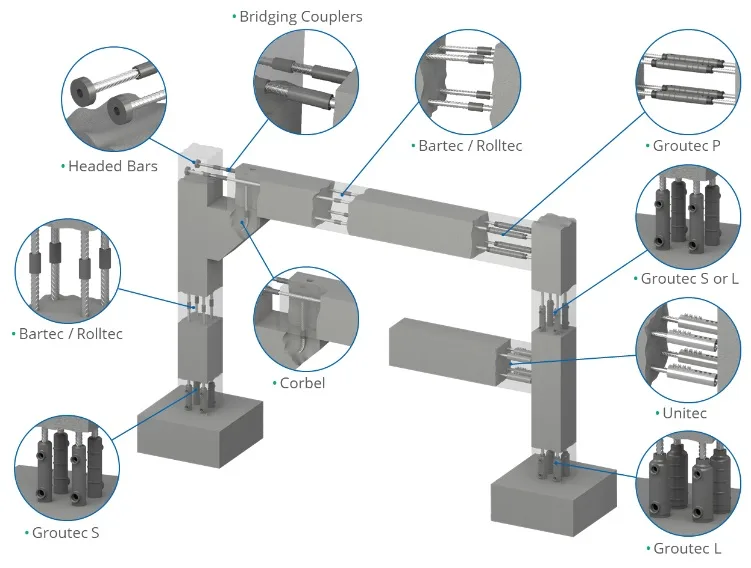

Dextra offers a range of Groutec couplers that are tailored to various construction needs, ensuring compatibility with different project requirements and designs. The flexibility and versatility of these couplers make them a valuable choice for construction professionals aiming for efficiency, safety, and quality in their projects. The company;s products find application in various sectors, including residential and commercial buildings, data centers, process plant pipe racks, mass housing projects, and more.

Features of Groutec couplers;

Groutec is a mechanical splicing system designed specifically to connect two precast elements without the need for in-situ wet concrete joints. It is designed and manufactured in compliance with Eurocode 2, BS 8110, ACI 318, IBC, and AASHTO standards. Groutec comes in three varieties:

- Groutec L – Large Tolerance, allowing for larger axial misalignment

- Groutec S – Slim Body, facilitating slim column and panel connections

- Groutec F – Fully grouted, eliminating the need for threading on rebars

It can be used with non-shrink grout readily available from major manufacturers. All couplers are marked with codes for traceability, including material certificates, inspection and test reports, and mold numbers. Design files are compatible with CAD and BIM tools.

Use of Groutec Couplers for Pipe Rack Application:

Pipe racks serve as a practical solution for routing overhead piping, especially prevalent in the oil and gas industry. Given the substantial expenses associated with steel construction, along with the need to meet stringent fireproofing regulations and adhere to tight project timelines, precast concrete pipe racks have emerged as a cost-efficient alternative for process plants. These structures primarily consist of columns and traverse beams, making them exceptionally suitable for prefabrication. The integration of couplers into this construction method significantly accelerates and streamlines the assembly and installation processes, ultimately leading to economical and efficient outcomes.

In this context, couplers play an important role by providing secure and fire-resistant connections between precast elements. Their ability to swiftly and precisely join these components enhances structural stability while complying with safety standards. Additionally, couplers facilitate alignment adjustments, accommodating potential variations during construction. This adaptability ensures precise and error-free assembly.

Furthermore, couplers simplify the grouting process, enabling controlled pouring of grout to establish robust bonds between the precast elements. This controlled grouting not only ensures structural integrity but also contributes to the overall efficiency of the project. As a result, the combination of precast concrete and couplers has become a preferred choice for constructing pipe racks in the demanding environments of the oil and gas industry, offering a cost-effective, fireproof, and expedited solution.

We have focused on case study wherein Groutec couplers were used for pipe racking applications

Case Study – RIL Jamnagar Refinery:

| Sr | Parameter | Description |

| 1 | Customer | Reliance Industries |

| 2 | Location | Jamnagar, Gujarat, India |

| 3 | Year | 2013-2015 |

| 4 | Rebar Dia Range (mm) | 25, 32 & 40 |

| 5 | Quantity of Groutec Couplers (Nos) | 135,000+ |

Execution Methodology:

In this project, Groutec couplers played a crucial role in connecting precast elements vertically, forming the H frames of the pipe racks. Here’s a step-by-step process:

- Installation at Precast Yard: Initially, the couplers were installed on the reinforcement bars right in the precast yard.

- Casting in Concrete: Subsequently, the couplers were cast in concrete after closing the formwork.

- Transport to the Site: These precast elements were then transported to the construction site for further assembly.

- Top Element Placement: During assembly at the site, the top element was carefully positioned over the bottom one.

- Grout Application: The next crucial step involved pouring grout (specifically Sika grout in this case) into the couplers. As the top element was lowered, its protruding bars seamlessly inserted into the coupler cavities, causing the grout to overflow.

- Temporary Bracing: To ensure stability and structural integrity, the assembly was temporarily braced until the grout completely dried.

- IAPMO Certification: Notably, the couplers obtained certification from IAPMO, a mandatory requirement for this project.

Key Benefits of Groutec Couplers:

- Faster construction cycles, at least three times faster compared to cast-in-place methods.

- Reduced grout consumption, resulting in fewer man-hours.

- Enhanced safety due to only short protruding bars.

- Engineered shape for optimal concrete bonding.

- Capability to accommodate bar misalignment.

Whether connecting precast elements in pipe racks for the oil and gas industry or contributing to the rapid rise of precast construction in various sectors, the Groutec Coupler proves its mettle. Its robust design, ease of installation, and superior load-bearing capabilities make it a valuable addition to any construction project. With its potential to enhance structural integrity and reduce construction time, the Groutec Coupler represents a promising solution for reinforcing concrete structures. As the construction industry continues to evolve, innovations like the Groutec Coupler are instrumental in meeting the demands of modern infrastructure projects.

About Dextra

Dextra is a leading manufacturer, supplier, and exporter of engineered rebar splicing products. They’ve developed a wide range of solutions to boost efficiency for contractors and consultants worldwide, used in diverse projects from high-rise buildings to power plants and bridges.Their precast solutions encompass a comprehensive range of products and services designed to optimize the efficiency and reliability of precast concrete applications. Dextra’s commitment to innovation and quality is evident in their precast connection systems, which facilitate strong and durable connections between precast concrete elements, ensuring the structural integrity of projects ranging from buildings to bridges.

What sets Dextra apart is their dedication to customization, tailoring precast solutions to meet the unique demands of each project, and providing expert engineering support to guide clients in selecting the ideal components. Their global presence, backed by ISO 9001 certification, underscores their commitment to delivering high-quality precast solutions to construction projects worldwide, making them a trusted partner in the industry.

With a presence on every continent and a network of subsidiaries and long-term partners, the company is well-equipped to serve clients globally, ensuring timely support and reliable precast construction solutions. Dextra’s precast offerings contribute to the success of over 15,000 major construction and industrial projects worldwide, reinforcing their reputation as a top-tier provider of precast solutions that enhance construction efficiency and durability.

Dextra India

215 Atrium 2, Tower 2, Ground Floor, Unit no. 001, Andheri – Kurla Road, Hanuman Nagar, Andheri East 400059, Mumbai, India.

Phone: +91 22 2838 6294 ext 217 / +91 80 9746 1155

Email: bjog@dextragroup.com

Website: dextragroup.com