Presently authorities are probing into the cause of the Morvi bridge collapse, and hence I can only comment on the fundamentals. But doesn’t this collapse (and many more in the past) demand that we need a predictive analysis which can forecast when a bridge shall collapse with a certain degree of reliability index. Such analysis will prepare us to avoid these collapses in future.

The situation of bridges around the country isn’t that good either. Based on a survey reported in 2017, it is found that, 6551 NH bridges are structurally deficient and out of these bridges, 86% are below the age of 49 years[1]. This statistic comprises 5591 minor bridges, 664 major bridges and 296 extra-long bridges[2]. In the conventional engineering techniques, you don’t know beforehand which one of these will collapse first or someone or our own loved-ones become its victim. Is there any salvation? Read on …

Cause of Failure Leaving aside the deficiency in design and details, “deterioration” is the primary cause of such failures. When the structural performance falls below a specific threshold due to deterioration, it is an end of life. Major deteriorations include corrosion, fatigue, loss of strength, loss of prestress, etc. You would ask me,“If these factors are known, why do bridges still continue to collapse? Can’t we control them?” Off-course yes! But there is a fundamental block among the engineering fraternity in general …

Gujarat Morbi Bridge Collapse

The Real Cause of Failure

A leading bridge professional has said the following profound statement, “… structures are undergoing deterioration faster, because the mechanism of degradation was not understood well at the time of construction”[3] and was not taken into account in their planning and design.

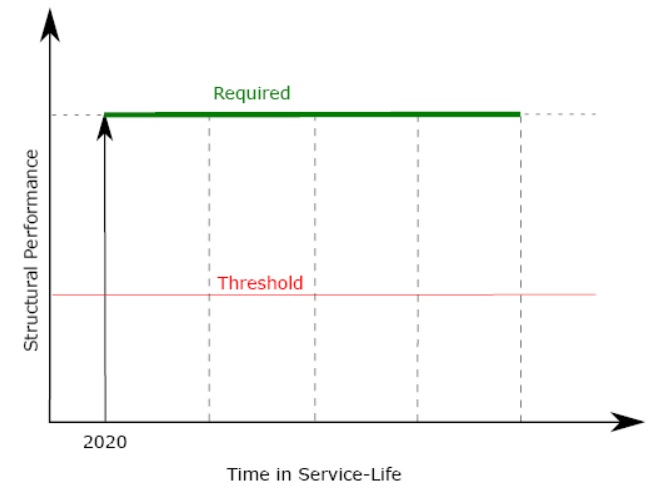

In conventional engineering we were not taught to consider deterioration of infrastructures. Remember your 4th year of engineering, we studied ‘Design of structures’. We were taught to design for a given distributed load, or a bending moment, but we were not taught to design a structure considering, it will corrode in 10 years or how to consider the effect of corrosion in design. Thus in essence, the conventional engineers consider the performance of structures as non-degrading over time, see Fig. 1. As such they are unable to handle deterioration at a detailed level. Dr. Angst recommends that one has to do a detailed study or go for higher education, such as PhD in the subject to understand it[4].

To give you an analogy, suppose you did not account a particular load in design. What will happen when that load comes on the bridge – it fails. Since the engineers did not account deterioration in design and they are not taught how to handle it – this is the real reason for infrastructure failures.

In a common Structural Audit, engineers perform tests on the bridge and evaluate only its instanteneous performance at time t1 (see Fig. 2). They consider the same structural capacity of the previous audit until the consecutive audit is done, at t2. The reason for this is the explanation behind Fig. 1.

It is possible that bridge failure can occur before your next audit (t2) (Fig. 2), because you gain no knowledge about its future behaviour from a conventional audit. Mostly the decision to do an audit is initiated based on visual inspection. The New Zealand Transport Agency confirmed that ‘visuals can be misleading’, because the Sorrell Causeway Bridge suddenly collapsed with no obvious visual distress[5]. This indicates that many, bridges may already be in a severely weakened state while still passing a visual inspection test without detection of damage.

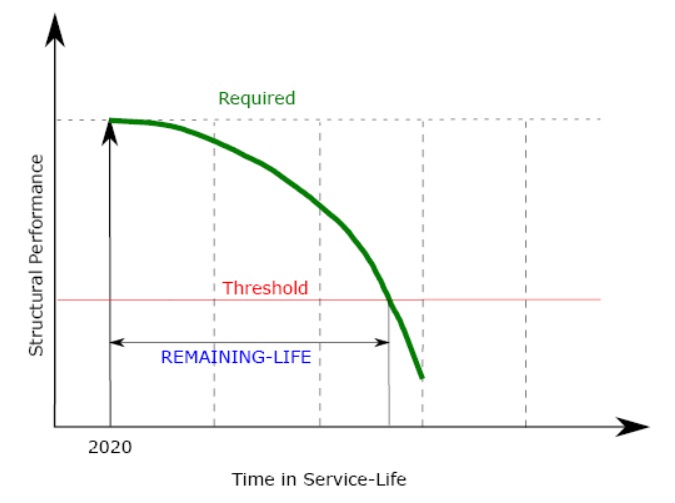

It is clear that Structural Audit of a bridge cannot prevent a bridge collapse. We need to be elevated to the next level of engineering. Now, it is possible to tell you just exactly when your bridge is about to fail or when it is due for a major rehabilitation, see Ref. [6, 7] using Remaining-Life Analysis (RLA). In RLA you are empowered through a deterioration analysis to “see” the behaviour of your bridge in the years to come and inform you proactively when you have a dangerous situation in future, see Fig. 3. RLA proactively tells you the future behaviour

of your structure through strategic data fusion of SHM/NDT and performance model of the structure through Bayesian updating[6]. Bayesian updating empowers you to realistically analyse the behaviour and lets you account for uncertainties such as design/execution deficiencies, deteriorations and shocks and determine the remaining useful life of your project with confidence.

The most important benefits you get from RLA is seen in Fig. 4. As you already know the behaviour of the bridge in the coming years you are forewarned of its end of life. Usually when there is a sudden collapse you are into panic and might make a hasty decision, unwise for the long run. But because you “see” through RLA you are prepared to combat future rehabilitation by accumulating funds, rather than digging a well when there is fire. Plus you can do a proactive life cycle planning for your bridge (which is impossible in a structural audit), that can minimise your operation cost, and can achieve a target life extension with confidence. I always say, “Bridges don’t demand RLA, they deserve it”.

Conclusion

Structural audit is ok for instantaneous testing, but it cannot provide us confidence about the future performance of the bridge. To avoid bridge collapse, it is mandatory that the remaining life of the bridge is analysed. Remaining-Life Analysis (RLA) is about care and honesty, which can provide confidence and peace of mind to you. It benefits those who really want to see their Nation as a super power by avoiding its enormous losses from infrastructure failures. There are three qualifiers, to check if RLA is for you: 1) You are wise and knowledgeable, 2) You are proactive, and 3) You don’t compromise for the Nation. If you fit in all three criteria, the world is open for you to succeed.

References

- [1] S. Joshi, N. Naga, and U. Rajesh. Experience of Management of Bridges Prior to and Post Evaluation of BMS on NH network of India. In Proceedings of IABMAS 2018, Melbourne, Australia, 2018.

- [2] S. Joshi and S. S. Raju. Indian Bridge Management System – Overview and Way forward. In Proceedings of IABMAS 2018, Melbourne, Australia, 2018.

- [3] P. S. Marsh and D. M. Frangopol. Reinforced concrete bridge deck reliability model incorporating temporal and spatial variations of probabilistic corrosion rate sensor data. Reliability Engg. and System Safety, 93(3), 2008.

- [4] U. M. Angst. Challenges and opportunities in corrosion of steel in concrete. Materials and Structures, 51(4), 2018.

- [5] R. A. Rogers, M. Al-Ani, and J. M. Ingham. Assessing pre-tensioned reinforcement corrosion within the New Zealand concrete bridge stock. Technical report, NZ Transport Agency research report 502, Wellington, New Zealand, 2013.

- [6] S. A. Faroz. Assessment and Prognosis of Corroding Reinforced Concrete Structures through Bayesian Inference. PhD thesis, Indian Institute of Technology Bombay, Mumbai, India, 2017.

- [7] S. A. Faroz and S. Ghosh. Bayesian integration of NDT with corrosion model for service-life predictions. In Proceedings of IABMAS 2018, Melbourne, Australia, 2018.

Authored by;