Times are changing in construction with the evolution of newer technology. Rapid construction and the huge demand for energy efficient construction materials are on the rise. One such technology is LGSF, which requires a shorter construction period compared to that for a conventional building system. Due to various economic, structural and ecological benefits, this construction technology is getting high acceptance. The need to lower the production costs involved in the construction of buildings is also estimated to be one of the key factors responsible for LGSF market growth. The use of LGSF technology provides ease of installation along with a reduction in the cumulative project completion period owing to prefabricated steel structures. One renowned organisation providing LGSF technology in India is Mitsumi Housing Pvt. Ltd. The company has bagged the prestigious PMAY Awas Yojana project of the Government of India of 750 crores INR. With India’s largest LGSF factory they are sure they can be instrumental in helping you with your next build with this novel and rapid construction technology.

Constrofacilitator had a one-to-one discussion with Mr. Shahid Badshah, Business Head, Mitsumi Housing Pvt. Ltd. Mr. Shahid has experience of more than 16 years on LGSF technology. He has deep knowledge of working with customers daily and his aim is to make the LGSF technology the ‘new normal’ by creating awareness. He has worked closely with companies’ senior executives to analyze the dimensions of the problem or the opportunity to determine the best course of action to achieve desired results.

During the discussion, he shared insights on the LGSF market potential market driver, assembly and reaction, advantages and many more other details.

Here are the excerpts of the interview with Mr. Shahid Badshah.

Give us an insight into the company’s LGSF factory setup and FRAMECAD High-Speed Machines used for manufacturing rapid LGSF construction technology?

Mitsumi Housing India is a 28 years old construction company that is a part of the Mitsumi Group of Companies distribution network worldwide known for their traditional multi-storeyed building construction. Mitsumi Housing India is undertaking rapid construction work in India. Mitsumi has a large financial background that deals with bigger projects, once you are associated with us you join a grand lineage of history.

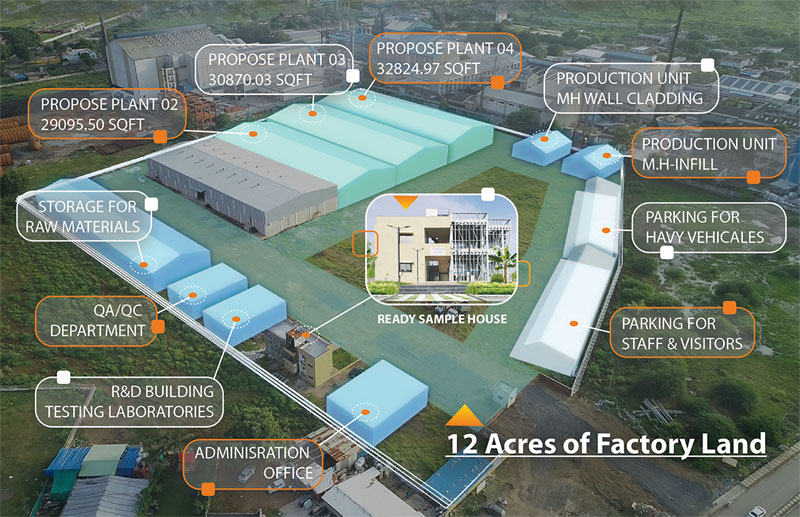

We have India’s Largest LGSF factory. The factory comprises the structural in-house design team, FRAMECAD machines, and ready steel stock.

There was a dire need for rapid construction technology in India, foreseeing the need to market the management of Mitsumi Group of Companies invested in the world-famous LGSF brand for Hardware and Software FRAMECAD European machines, which are precision high-accuracy driven machines.

We house four high-speed FRAMECAD machines which include, latest 89 and 150 mm sections at our plant in Kosamba, Gujarat – India. We can achieve accelerated delivery of cold-formed steel (CFS) construction with automated engineering and detailing software that integrates with our world-leading factory control software. They are completely computerized through which we can produce from 0.77 mm to 2 mm gauge steel. Our in-house LGSF Design Team is trained on this specialized software that enables us to give the best output to our clients.

Discuss the company’s recently bagged PMAY Awas Yojana project of the Government of India?

Through the Global Housing Technology Challenge – India (GHTC-India) we have been awarded the prestigious Pradhan Mantri Awas Yojana project. Affordable housing is still a major concern in India as there is a need to provide economical housing in the shortest time frame. We abide by Pradhan Mantri Awas Yojana’s vision of ‘Housing For All’. Our factory and technology have been developed around this ideology for producing faster mass housing in India. The focus is on ‘double-the-speed’ concept compared to the traditional mode of construction. LGSF frames are flexible, lightweight and manufactured and disassembled off-site, they can be quickly assembled and installed on-site, making them ideal for mass housing. This form of dry construction also requires minimal manpower. For high-rise buildings in mass housing hot rolls are being used with light gauge steel which reduces the entire weight of the building as finishing is quite superior.

Building Materials & Technology Promotion Council (BMTPC) has approved LGSF technology for mass housing in India.

How is Mitsumi creating awareness on LGSF technology in India?

LGSF technology is getting more acceptability because of big players like Mitsumi. We are doing a weekly program each Wednesday to create awareness about the technology. For us, the awareness of technology comes first. Previously the Indian LGSF market was quite a niche, but since we have joined the market there has been a rise in market players too and evolution will continue. We are also organizing skill development programs all over India, so that maximum people get aware of the LGSF design and technical aspects.

Steel prices in the market are in ‘seesaw condition’ at present, how does the company keep its book of stock order?

We bulk buy the material and possess the capability of holding tonnes of stocking capacity. We hold our stock for our clients for a certain dateline and maneuver accordingly. Our full effort is on providing the best finish for the client. We try to keep our inventory constant. We also have our in-house steelyard.

How does the company undertake structural design, assembly erection on-site?

All the engineering is done before the steel frame components are produced. Beam load, design, cladding material, seismic zone criterion all these important factors are defined and predefined, engineered and pre-engineered before printing the material. It is a complete solution. The customer gets fully cut and material from us. Only he needs to assemble the frames, and we also provide assembly drawings for the customer. All these things make jobs easier on site. Erection and assembly are done very intelligently as per modules and pre-planned requirements.

One specialty of Mitsumi LGSF is that for any big project we phase out the erection and assembly in such a way that faster construction can be done by the assembler. We do this by providing him the right material at the right time. These materials require less area to stock.

Discuss the hybrid construction technology provided by the company.

Our technology construction technology uses the combination of light gauge and heavyweight steel whenever it is required. Hybrid Construction Technology is used for High – Rise / Multi – Storeyed Residential Buildings. We construct all steel columns in grid pattern formation of PEB (Hot Rolled Steel) from Cellar Slab Level to the Roof Level (Top to Bottom). We provide hybrid construction based on the customized structural requirement of the customer.

What are the market drivers for Mitsumi LGSF solutions in India?

Many factors drive this market for Mitsumi. One of the prime factors is marketing the technology, not the company. People have been appreciative of this approach. Secondly, there is a demand owing to the Pradhan Mantri Awas Yojana project.

Other factors such as lack of natural elements like sand, labour shortage, lack of technical people on the project site are also driving the demand for LGSF technology. Transportation is also an important factor. Moving of building materials in distant localities is difficult, with LGSF we can send in full building components in trucks which is easier. We are also coming with ‘kit home’ and ‘kit rare house’ concept wherein you just need to choose the house and we will make it ready for you.

Another important driver includes the demand for high-quality construction, since LGSF components are manufactured in a factory-controlled environment there are no chances of low construction at all. A customer knows what he is getting.

Deadline-driven projects are also a pivotal factor driving the market, for traditional construction lack of materials often affects project deadlines, but in LGSF there is no scope of that and hence the more feasibility of meeting project deadlines.

How are Mitsumi steel frames performing in earthquake-prone zones?

The raw materials used by us are 250 to 550 MPa high tensile and heal strength steel. These are highly galvanized which is 270 gsm for galvanized ions and 150 gm galvalume steel. This steel has got tensility, it expands, contracts and comes back at the same pace. The steel acts like a woven basket so it is difficult to break. This steel has been proven to be highly earthquake resistant with proven tests and methodology.

What are the advantages of the company Galvanized Coated Steel coils?

Our Galvanized Coated Steel coils are highly corrosion resistant. It comes with extended durability, having the strength and formability of steel plus the corrosion protection of the zinc-iron coating. The zinc protects the base metal by acting as a barrier to corrosive elements, and the sacrificial nature of the coating. The raw material used in steel coils is of the highest quality.

How is the acceptance of LGSF technology in mid-rise construction and commercial spaces like hotels?

Our LGSF technology is perfectly fitted for G plus 4 / 5/ 7 building construction. Several tourism boards of states are also considering this technology. LGSF can appetite and appeal to new age thinkers who want a different faster and aesthetic construction technology.