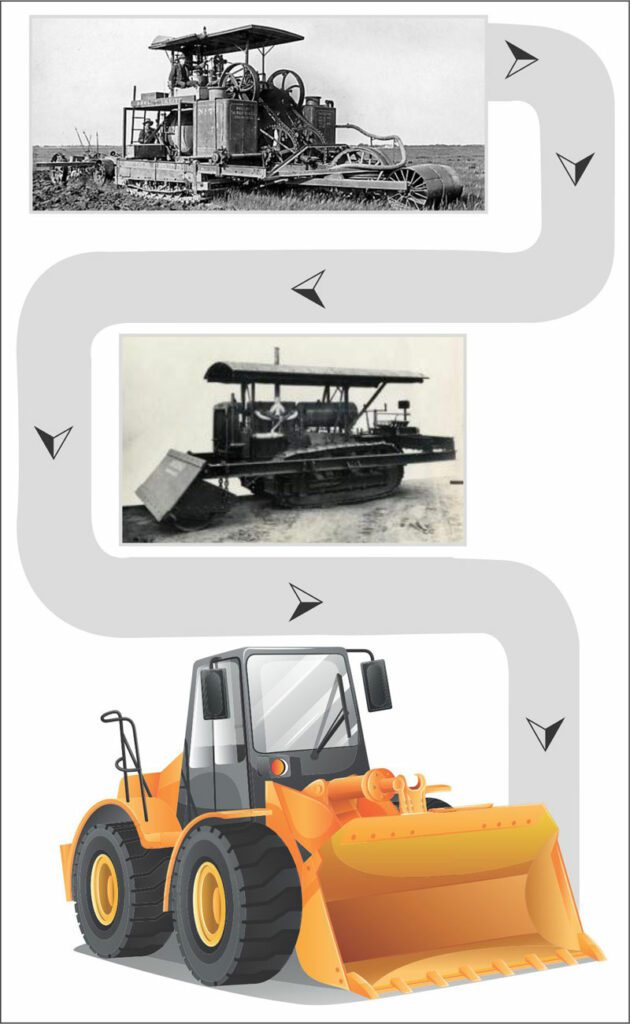

The word “dozer” goes back to the 19th century when it was denoted as an operating mechanism attached to the front of track-type tractors. It was used to spread loose dirt out overfill. With time it has gone through an evolution and is used across the globe to perform tougher construction jobs.

Do you know about the evolution of Dozers?

Initially, the dozer was referred to as a steel plate and an operating mechanism attached to the front of track-type tractors. They were made of wood and affixed to the front end of a pole that was pulled by horses or oxen. Their main purpose was to spread loose dirt out overfill as it accumulated. With time a dozer blade was introduced in front of the machine that was controlled by a rope windlass fastened to the tractor’s mainframe. In mid-1940 manufacturers began developing their line of dozer blades that met specifications and quality standards. They were available in both cable and hydraulically controlled types. Soon these track-type tractors quickly became known as a “dozer” and were used for different projects that included highways, dams, canals, etc. In the beginning, cable controls were used for material lifting. Eventually, dozers progressed to having an onboard computer that could control the blade for the operator to produce a predetermined design. It has gone through an evolution, modern dozers are used for jobs such as moving material or finishing grading. There’s a dozer available in small, medium or large sizes. There are now wide choices of undercarriage, drivetrain and blade configurations and many more other features. Today, the term dozer refers to the rugged machines built for tougher construction works.

Types of dozers and blades used in modern Indian construction

With the heavy investment, India plans to spend up to 111 trillion rupees over the next four years on infrastructure projects. This has further led to the widespread adoption of bulldozers for roads, railways and airports. Bulldozer manufacturers are now focused on technological advancement that will support the machine’s compact variants and features that will perform better on uneven terrains. Now, built-in intelligence is also available so you can work flawlessly with leading GPS grade control systems. They also come in multiple variants to meet power or handling requirements. There are different types of dozers used across the road, mining, railway and other works in India.

Different types of dozers

Crawler Dozers

The crawler is a tracked dozer that appears much like a tractor. This heavyweight machine is used to hold materials from one place to another. Modern crawler dozers are equipped with a Hydrostatic Transmission System that allows for variable speed selection or intermediate speed selection. The mainframe is designed with advanced Computer-Aided Engineering (CAE) technology that consists of a track frame combined with connecting bars. The modern models come with dual-path closed-circuits with two variable displacement piston pumps and two 3-speed variable displacement travel motors. Travel motors and final drives are mounted inside the track shoe for protection from rocks and stumps and for improving durability. The life of undercarriage and reliability are greatly extended by the use of large-size links, pins, bushings, and unique dust seals. Dozers use dynamic brakes to ensure safe operation. The 3-axis PPC valve and ergonomically designed joystick provide light operating effort and excellent blade response. It also features a PCCS (Palm Command Control System) joystick that controls all directional movements. The engine hood and well-located operator seat provide excellent visibility to the blade. This clear blade visibility greatly increases grading efficiency and reduces operator guesswork. The models are designed to maximize the blade curvature. The large blade radius allows the rolling-up performance of the material to be maximized by utilizing the entire blade. This provides excellent productivity while maintaining the grading capabilities.

Wheeled Dozers

This machine is also referred to as a tire dozer and is normally larger than a crawler. Wheel dozers come with robust structures that achieve multiple life cycles and withstand the toughest conditions. It is equipped with a full box-section rear frame that resists torsional shock and twisting forces. Axle mounting is optimized for increased structural integrity. The models now come with Steering and Transmission Integrated Control System that turn directional selection, gear selection and steering into a single lever. Powershift transmission is consistent through integrated electronic controls that utilize Advanced Productivity Electronic Control System. Latest wheel dozers also come with fuel-saving features such as mechanically actuated electronic unit-injection system, engine-idle-shutdown and engine-idle kick-down systems, delayed-engine-shutdown system and on-demand and hydraulically driven cooling fan. The operator cab features automatic temperature control, touch-screen display with soft keypad, electro/hydraulic parking brake and the Comfort III seat with air-ride suspension and integral controls.

Mini dozers

A mini dozer is often known as a compact dozer used for tasks that require extra mobility and flexibility than additional massive equipment. The modern mini dozers feature technology enhancements and a new low-emission, fuel-efficient engine. It comes with a new lower sloping hood line that improves visibility to the peripheral view and the blade’s cutting edge to increase finish grade efficiency. The models can deliver a blade capacity of 1.85 to 1.98 cubic metres, 92 hp and an operating weight of 8,319 to 8,627 kg. Eco mode in these machines automatically allows the engine to deliver maximum speed and power until the load decreases. The new model also features a 25-cm primary display with colour touchscreen and provides access to many of the standard and optional advanced technology features. The slope Assist feature in mini dozers improves operator efficiency when working on slopes by providing the chassis in the cross-slope direction. This also complements operator blade control input, allowing the operator to finish grade easier, quicker and with less effort.

Hybrid dozers

These dozers make use of electronic components and are equipped with a combination of blades that can work both in waterlogged and tough terrains. The newer series of hybrid dozers delivers top performance in load response, maximum torque, power and fuel economy. The turbocharged engine with an Air-to-Air intercooler relies on well-proven multi-injection technology to maximise torque back-up and fuel efficiency with reduced engine noise and vibrations. The hydrostatic transmission on the common rail FPT Industrial engine delivers best-in-class pulling capacity and controllability. In the new models the radiators are mounted with no overlap, so that each radiator receives fresh air, maintaining constant fluid temperatures. The hydrostatic fan continuously adapts its speed to match the real cooling demand, reducing power absorption. The reversing mode reduces maintenance needs and lengthens cleaning intervals. All the working parameters can be customized by the driver for excellent machine controllability and faster cycle times. The cab controls offer a wide choice of electronic settings and automated functions that make the driver’s job easier.

Different types of Dozer Blades

The above dozer types can be further classified based on the blades used. Different blades serve different purposes, can handle different types of materials and can handle a range of load weights.

- Straight Blades (S-Blade) – It is the smallest blade dozer and does not have surface wings, this blade is assigned to the lower rear corners of the module. This blade attaches to the arm in the lower back corners of the blade.

- Universal Blade (U-Blade) – This blade has long edges and a curved shape that makes it ideal for transferring material to more extended parts. It is ideal for pushing materials across long stretches of land. It’s the largest blade type in both height and width and is best used with soft- to medium-density soil.

- S-U (SEMI-U) Blade – This type of blade combines the S-blade & U-blade and provides sufficient penetration. It is ideal for pushing soil across long distances.

- Angle Blade – This type of blade is attached to the center of the bulldozer’s panel. It is for moving debris to the side since it can angle close to 30 degrees left or right.

- Power-Angle-Tilt (PAT) Blade – This blade can be controlled from the cabin & it can tilt at any angle in almost all directions. It is used for scraping, land clearing, leveling, backfilling and grading.

Conclusion

Explained above are the different types of dozers and the features catered by manufacturers to propel the demand for multi-terrain in India. There is a high rate of adoption of technologically advanced equipment in the construction industry, in order to enhance the quality of the work. Significant investment in the development of rail infrastructure, highway construction and metro rail projects along with government initiatives for housing schemes are likely to propel the demand for dozers in India.