Concrete remained the backbone of global infrastructure, while rising durability demands, environmental concerns, and accelerated project timelines reshaped how it was designed, specified, and used. In 2025, innovation in concrete materials focused on reducing emissions, extending service life, and delivering consistent, predictable performance on site. These advancements directly addressed real-world project challenges faced by engineers, consultants, contractors, and public-sector agencies.

Below are the most relevant concrete material innovations shaping construction practice today.

1. Carbon-Capture Concrete

This innovation allows concrete to absorb carbon dioxide during production, which becomes locked in as stable minerals. It works best in precast elements and flatwork applications, providing both environmental benefits and predictable performance.

- Supports low-carbon construction targets

- Compatible with existing batching systems

- Meets standard strength and durability requirements

2. Ultra-High-Performance Concrete (UHPC)

UHPC offers high strength and excellent durability for demanding structures such as bridges, metro stations, and coastal projects. Its composition resists cracking and corrosion, making it suitable for demanding applications.

- Supports thinner sections and longer spans

- Protects reinforcement from corrosion

- Lowers maintenance and overall lifecycle costs

3. Recycled Aggregate Concrete

Recycled aggregate concrete uses processed construction and demolition waste as a partial replacement for natural aggregates. Many public works departments now allow this material for roads, pavements, and utility structures.

- Reduces demand for natural sand and stone

- Suitable for large-area infrastructure works

- Diverts waste from landfills

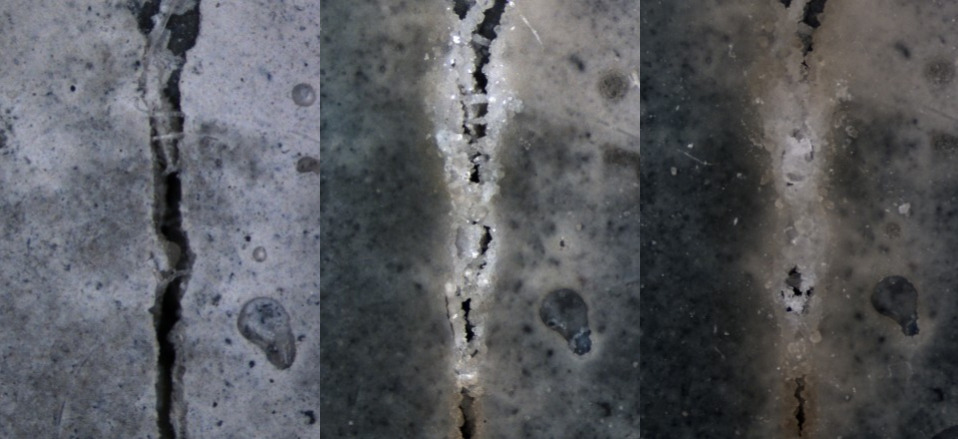

4. Self-Healing Concrete

Self-healing concrete can seal small cracks on its own when it encounters moisture. This technology targets durability rather than strength improvement and suits structures exposed to water and weather.

- Limits water penetration

- Slows reinforcement corrosion

- Reduces long-term repair frequency

5. 3D-Printable Concrete

3D-printable concrete supports faster construction without traditional formwork. Engineers use it for repetitive or remote construction where speed and labor availability matter.

- Allows controlled material placement

- Supports rapid project execution

- Reduces site waste

6. Graphene-Enhanced Concrete

Adding a small amount of graphene can strengthen the concrete and make it less permeable. This makes it more resistant to cracks and better suited for harsh environments.

- Improves crack resistance

- Enhances long-term durability

- Allows lower cement usage in some mixes

7. Bio-Based and Alternative Concrete Materials

Bio-based concrete materials replace a portion of cement or aggregates with natural or agricultural by-products. These materials suit low-rise buildings and non-structural components.

- Uses renewable or waste-derived inputs

- Supports sustainable building standards

- Lowers embodied carbon

8. AI-Optimized Concrete Mix Design

AI-driven concrete mix design improves accuracy and consistency in material performance. Engineers use data models to predict strength, setting time, and durability before production.

- Reduces trial-and-error batching

- Supports low-carbon mix development

- Improves quality control

9. Low-Carbon Cement

Low-carbon cement such as Limestone Calcined Clay Cement (LC³) has gained traction in India. Developed through Indian research institutions and industry collaboration, it reduces clinker content without compromising performance.

- Cuts cement-related carbon emissions

- Uses locally available materials

- Suitable for mass infrastructure projects

10. Smart Concrete with Embedded Sensors

Smart concrete integrates sensors to monitor curing, temperature, and structural behavior. Project teams use this data to make informed decisions during construction and operation.

- Improves construction monitoring

- Supports asset management systems

- Enhances structural safety

Practical Outlook

Concrete material innovation in 2025 focuses on buildability, durability, and environmental compliance, not experimental concepts. Most of these solutions already support pilot projects or active deployment. For engineers and government clients, the priority now lies in standard adoption, approvals, and training, ensuring these materials deliver consistent value on real sites rather than only in laboratories.