Concrete Cloth (CC) is an innovative material composed of a flexible aluminate cement powder-impregnated fabric that rapidly hardens upon hydration to form a thin, durable, waterproof, and fire-resistant concrete layer. The material is delivered in the form of rolls at various thicknesses which allows their placement without a need for a plant or mixing equipment. Their ease and rapid installation facilitate their use in a wide range of applications such as slope stability, ditch lining and fast deploying shelters to name a few. The typical concrete cloth consists of a three-dimensional fiber matrix, containing a dry concrete mix with backing by PVC on one surface of the cloth to make it waterproof. Hydrophilic fibers on the other surface support the hydration by drawing water into the cement. The canvas material can be hydrated by spraying or by kept immersed in water.

The concrete cloth has a vast scope of application such as in slope protection construction, mining, overlaying on underground pipelines, agriculture, Military application and much more. The primarily concrete cloth was invented for urgent applications for construction of shelters. The concrete cloth can be quickly and effortlessly nailed, stapled through or covered with a good quality adhesive for shelters, the pathway for vehicles or pedestrians and unlimited applications. Once set, this cloth covers the concrete, prevents the crack propagation & imparting a secure plastic failure mode.. The preparation of concrete cloth may also hamper the effective hydration process by shielding the cement powder from water, affecting the mechanical properties of hardened cloth.

Advantages of Concrete Cloth

- Rapid Install CC can be laid at a rate of 200m2/hour, up to 10 times faster than conventional concrete solutions.

- Easy to Use The concrete is pre-mixed so there is no need for mixing, measuring or compacting.

- CC is also available in man-portable rolls for applications with limited access.

- Lower Project Costs

- The speed and ease of installation is more cost-effective than conventional concrete, with less logistical complexity.

- Eco-friendly CC is a low mass, low carbon technology that uses up to 95% less material than conventional concrete for many applications.

- The fibre reinforcement prevents cracking, absorbs energy from impacts and provides a stable failure mode.

- Durable CC is 5 times as abrasion resistant as standard OPC concrete has excellent chemical resistance, weathering performance and UV resistance.

- CC comes with durability above 120 years when used in erosion control applications.

- Flexible CC has good drape characteristics and will closely follow the ground profile and fit around existing infrastructure. Unset CC can be cut or tailored using basic hand tools.

- Unlike regular concrete, Concrete Cloth materials can be installed in the rain and other wet conditions, virtually eliminating rescheduling due to weather conditions.

- It can be either hydrated by spraying concrete cloth or immersing it completely in water, once hydrated it remains effective for up to 4 hours, becoming 80% stronger within 24 hours.

- Concrete Cloth material has a low alkaline reserve and a low wash rate for a minimal ecological impact.

- Concrete Cloth material facilitates ease of installation- fabric can be hung vertically, laid in trenches, or cut and formed into shapes to create a durable layer of concrete.

Applications of Concrete Cloth

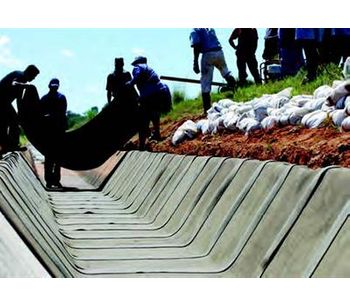

The unique structure of Concrete Cloth GCCM makes it easy to install for a variety of applications, such as channel lining, slope protection and containment. It can be hung vertically, laid in trenches or cut and formed into irregular shapes. Unlike regular concrete, Concrete Cloth materials can be installed in the rain and other wet conditions, which virtually eliminates project rescheduling. It has a low alkaline reserve and a low wash rate for a minimal ecological impact.

Channel lining

Concrete Cloth can be rapidly unrolled to form a ditch or channel lining. It is significantly faster, easier and less expensive to install than conventional concrete channel lining and requires no specialist equipment.

Slope protection

Concrete Cloth can be used to protect slopes from surface erosion. Compared to shotcrete it is typically faster to install, more cost effective, requires less specialist plant equipment, and eliminates the risks associated with rebound and debris.

Bund lining

Concrete cloth provides a cost-effective alternative for lining secondary containment bunds. It acts as an effective weed suppressant, reducing maintenance costs as well as providing additional levels of impermeability. Its ability to be installed quickly reduces time on site, whilst the availability of man-portable rolls allows for installation in areas with reduced access.

Remediation

Concrete cloth can be used to rapidly re-line and refurbish existing infrastructure suffering from environmental degradation and cracking. CC lined structures can be returned to operation in 24hrs from installation. Unlike structures are-lined with traditional concrete, the internal volume of CC lined structures is maintained ensuring that the channel design flow capacity is preserved.

Culvert lining

Concrete cloth can be used to extend the durability of new build culverts and to upgrade existing structures, preventing the need for asset replacement. The speed, ease and flexibility of CC offers significant technical and financial advantages, whilst offering a durable means of providing erosion protection. CC is used to replace, pour or spray concrete and bitumen coatings.

Erosion and weed control

One of Concrete Cloth’s greatest strengths is that it can be easily laid uniformly over slopes to quickly and effectively provide a simple but strong ground cover. Available in 3 thicknesses (5cm, 8cm, 13cm) it can be used in light and heavy traffic areas and can even be used to improve erosion at cattle feeding points into rivers. Because the outer surface of CC is a cloth it will naturally attract verdigre over the years and green up but because it is a cloth it can be painted in-situ to instantly camouflage it or it can be covered in honeycomb and turfed or seeded where a natural look is required.

Gabion Reinforcement

Gabions are in common use these days for embankment protection of railway cuttings, tunnel entrances and motorways to name but a few. They have many attractions because of teh size they can be built to and their relatively good appearance but when they start to reach the end of their design life they can be difficult to repair. In places where leeching of pullutants (or water) through the stones is an issue Concrete Cloth can be an answer. Simply attahing a layer of CC to the front using rings and hydrating will address any damage issue and a single layer on the slope before the gabions are installed will address any leeching issues. The water or pollutants can be diverted into a ditch using more CC and directed out of harm’s way.

Slope Protection

Slope weather protection is important to control soil erosion down slope as a result of direct rainfall and surface runoff. Protection can be a permanent slope covering or a temporary measure until the excavation has been backfilled. Uncovered slopes undergo surface ravelling and gulleying, leading to instabilities and safety concerns. Soil erosion is normally prevented by applying a thin concrete skin.

Deployable shelters

Concrete cloths can be used as a thin-walled concrete shelter for robust and lightweight deployability of hardened shelters that require only water and air for construction. The concrete canvas use as a shelter. Concrete Canvas Shelters provide much better environmental protection, increased security, saving effort and cost in long term as compared to conventional tent shelters.

Conclusion

The unique structure of Concrete Cloth makes it easy to install in a range of applications, such as channel lining, slope protection and containment. It can be hung vertically, laid in trenches, or cut and formed into irregular shapes. Unlike regular concrete, Concrete Cloth materials can be installed in the rain and other wet conditions, which virtually eliminates project rescheduling. It has a low alkaline reserve and a low wash rate for a minimal ecological impact.

Info source- reaearchgate, concrete canvas, nilex.com, geosolution.com, titanenviros.com, cs-nri.com, nilex.com, hynds.co.nz, newcivilengineer.com, environmental-geosynthetica.com, pintrest.com, concretecanvas.com, fostersupply.com, titanenviro.com, shotcrete.co.uk, alfreih.com.sa, expert.com.