Carbon Fiber Reinforced Polymer (CFRP) wrapping, is strengthening and retrofitting techniques used to reinforce and improve the load-bearing capacity of structural components such as columns, beams, walls etc. This process involves applying layers of CFRP composites to the surface of the structure, creating a strong and durable bond that improves its structural integrity.

Unlike traditional repair and retrofitting techniques that require demolition and reconstruction of part or whole failing structures, Carbon wrap goes right over the existing substrate. This technique reduces disruptions during repairs and results in substantial savings in terms of installation time and costs. The carbon wrap technology utilizes carbon fiber that has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members.

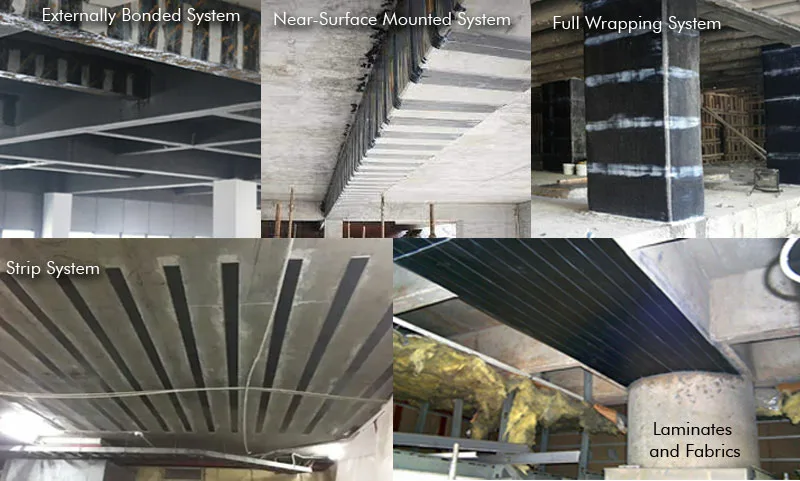

Different types of Carbon Fiber Reinforced Polymer (CFRP) wrapping systems

There are several types of Carbon Fiber Reinforced Polymer (CFRP) wrapping systems used for strengthening and retrofitting various structures. These systems differ in terms of their application methods, materials, and intended outcomes. Here are some common types:

- Externally Bonded System: This is the most common type, where carbon fiber sheets are bonded to the exterior surface of the structure using epoxy resin. It’s often used for increasing the load-bearing capacity of beams, columns, and slabs.

- Near-Surface Mounted System: Similar to the externally bonded system, this involves attaching carbon fiber strips to grooves cut into the structure’s surface. It’s effective for flexural and shear strengthening.

- Full Wrapping System: This system entails wrapping the entire cross-section of a structural member with multiple layers of carbon fiber sheets. It’s particularly useful for seismic retrofitting of columns and beams.

- Strip System:Carbon fiber strips are applied in a specific pattern to enhance the structural integrity and load-carrying capacity of the element.

- Laminates and Fabrics: Different types of carbon fiber laminates or fabrics can be used in combination with epoxy resin to reinforce various structural elements.

Applications of Carbon Fiber Reinforced Polymer (CFRP) wrapping systems

Carbon Fiber Reinforced Polymer (CFRP) wrapping, also known as carbon fiber wrapping or strengthening, is a versatile technique used to enhance the structural performance of various types of infrastructure. Here’s an overview of its applications:

1. Buildings:

- Strengthening Columns and Beams: CFRP wrapping is used to reinforce and upgrade the load-bearing capacity of columns and beams in existing buildings, especially those that were designed before modern seismic codes.

- Shear Strengthening: It’s applied to increase the shear capacity of structural elements like walls and slabs.

2. Bridges:

- Flexural Strengthening: CFRP wrapping is used to enhance the bending and flexural capacity of bridge girders, especially in cases where the bridge needs to carry higher loads than originally designed.

- Shear Strengthening: CFRP is used to improve the shear resistance of bridge components.

3. Infrastructure:

- Seismic Retrofitting: CFRP wrapping can be applied to enhance the seismic performance of various infrastructure elements, including buildings, bridges, and even pipelines, by increasing their ductility and energy dissipation capabilities.

- Repair of Corrosion-Damaged Structures: CFRP wrapping is effective for rehabilitating concrete structures that have suffered from corrosion-induced deterioration.

4. Historical Structures:

- Preservation and Strengthening: CFRP wrapping is employed to reinforce historical structures while maintaining their original aesthetics and architectural integrity.

5. Marine Structures:

Repair and Strengthening: CFRP wrapping is used in marine environments to rehabilitate and strengthen structures like piers, wharves, and seawalls that are exposed to harsh conditions.

6. Industrial Structures:

- Tanks and Silos: CFRP wrapping can be applied to strengthen cylindrical structures, such as storage tanks and silos.

7. Pipeline

- CFRP wrapping is used to repair and reinforce pipelines, both onshore and offshore, that may have sustained damage or deterioration.

Conclusion

The CRPF wrapping system emerges as a game-changer in the realm of building and structural applications. Its cutting-edge technology, coupled with its adaptability and precision, offers a revolutionary approach to enhancing repair, rehabilitation and strengthening processes. From reinforcing concrete to stabilizing structures, the CRPF wrapping system showcases its versatility across various construction scenarios. As the industry continues to emphasise efficiency, safety, and sustainable practices, embracing this advanced technology can pave the way for more streamlined construction workflows and improved project outcomes.