Bamboo is widely used for construction of houses/structures, foot-bridges, scaffolding walls etc. in bamboo rich countries. Several countries in Asia and South America depend upon bamboo as an important building material for construction of houses and low-rise buildings. As bamboo by nature is a highly perishable material, its use in construction has always been considered temporary and not surprisingly bamboo is replaced almost every year in most of the rural constructions. bamboo does not enjoy official recognition and patronage of contemporary engineers as it is with brick, steel, concrete or timber. There may be several reasons for this situation such as – low durability of bamboo, lack of technical know-how or facilities for preservative treatment, lack of authentic design data on various species, lack of information on design and reliability of jointing techniques and detailing. These factors might have led to resistance in using bamboo in their projects.

Another major reason for not including bamboo in construction projects appears to be due to the difficulty in procuring the right quality (grade) and species required in large quantities as demanded by housing projects, and bamboo not being included in specifications and schedules approved by government agencies. Besides, engineers normally trained in modern building materials like Reinforced Concrete (RC), steel generally hesitate to use natural building materials like bamboo in the absence of specifications and schedules approved by government agencies. Like most vernacular techniques, skill sets needed to sustain such techniques are also depleting rapidly.

There are about 75 genera and about 1250 species of bamboo. India’s bamboo resources (both variety and distribution) are the second largest in the world, with the first being China. Techniques of using bamboo for construction have been developed over years by local craftsmen, who recognize advantages of bamboo such as high strength / stiffness, easy workability and flexibility. When forest cover is fast depleting and availability of wood is increasingly becoming scarce, the research and development undertaken in the past few decades have established and amply demonstrated that bamboo could be a viable substitute of wood and several other traditional materials for the housing and building construction sector.

Important Characteristics of Bamboo

Main characteristic features, which make bamboo as a potential building material are

- High tensile/bending strength comparable to that of mild steel and wood

- High strength to weight ratio and high specific load bearing capacity

- Requires less energy for production compared to material like steel, plastics, aluminum etc.

- Physical-mechanical properties of bamboo which grows to maturity in 4 to 5 years compares favorably with that of hardwood which requires 40 to 50 years to attain maturity.

Bamboo species are generally hollow, but the size of the internal cavity depends upon the species, soil and climatic conditions. The outer skin of bamboo contains a small amount of silica, which improves its natural durability as well as the strength. Comparing the cost of bamboo and its behaviour under mechanical stresses, the choice of bamboo as a vernacular material for semi-permanent rural houses is justified. A programme of testing of bamboo for their physical and mechanical properties has been taken up at Forest Research Institute, DehraDun (Rajput et al., 1992 and Sanyal et al., 1988) and methods of testing have been formulated and standardized for about of 20 important species of bamboos.

Bamboo Standards

National Building Code of India (NBCI, 2005) has included a section for structural design of timber and bamboo. The code gives safe working stresses of bamboo for structural design. The safe working stresses for 16 species of bamboo are given in Table 1(NCBI, 2005). The code also mentions the factor of safety to be within 4-8 for bamboo based housing systems. The code also includes that with the decrease in the moisture content, the strength of the bamboo specimen increases exponentially and bamboo has an intersection point (fiber saturation point) at around 25 per cent moisture content depending upon the species.

Although bamboo was traditionally used for different construction works, especially housing in many areas throughout the world, scientific investigations established bamboo as a structural material and relatively not so old. India was one among the countries to recognize the need for generating a database on physical and mechanical properties of different species of bamboo. Indian standard methods on testing bamboo for evolution of physical and mechanical properties were developed in 1973 & 1976. (IS 6874: 1973 method of tests for round bamboos and IS: 8242- 1976 – method of test for split bamboo).

Selection, Sourcing and Grading of Bamboo

Bamboo being a biological material there is not much choice for Engineer/Designer to select a specified section (diameter, wall thickness) of his choice, in contrast to RCC, Steel, Timber, where there is a lot of choice and sections can be manipulated by processing or design. One normally selects a bamboo species based on availability and local experience. As there is no established scientific grading rule as with timber, the task of selecting the right bamboo grade could be tricky. Grading of bamboo may have to be carried out on the basis of outer diameter, wall thickness and permissible material defects like taper and crook, sourcing of bamboo of required grade may become critical for the specifier, especially when materials are required in large quantities. Selection and grading of bamboo continues to be based on local experience of craftsmen. Attempts have been made by researchers to grade bamboo on the basis of diameter (Rajput 1992 et.al) although wall thickness also limits the use of bamboo for structural application. Density of bamboo also determines the strength of bamboo (Rajput 1992 et.al, Janssen 2000).

Most of the sourcing in India is done through either Forest Departments, through contractors, societies and corporations to meet the needs of a particular craft including housing. Houses are also built in rural areas using homestead grown bamboo. Without proper grading rules it becomes difficult to implement large-scale housing projects.

Traditional Bamboo Construction

Bamboo houses are not wholly unknown to India. Villagers living in the vicinity of bamboo forests often construct them and live in them. It is hence known as poor mans material.

Bamboo houses in North-Eastern parts of India:

The general characteristics of the house in north-eastern parts of India are houses on the plains and those on the hills. The houses of the plains are simpler, mostly with mud plaster on walls and with mud floor. The houses on the hills are mostly on the ground with a plinth.

Bamboo house with thatch roof:

The most economical of its kind. Easy availability of bamboo and thatch makes it cheaper. Planning is confined to rectangular shape because of limitations of the construction system. Walls both inner and outer are of woven bamboo. Doors and windows are of wooden or even bamboo frames. The thatch is of straw.

Riang Bamboo House:

Riang tribals of Tripura build their houses with bamboo used as the primary material for construction. In some cases, even the thatched roof is made of bamboo leaves. These houses are typical hill dwellings, constructed on bamboo slits to create a large horizontal platform, the floor of the house. Bamboo posts are arranged on a square grid and inclined whole bamboo members strengthen these. A required number of posts extend above the surface of the floor platform to support the roof structure.

The plan of the Riang house is normally a long rectangle, with a covered verandah in front and an open verandah at the back. A large enclosed room is located between these verandahs. A single roof covers the front verandah and the room. The roof slopes downwards on either side.

Boards made of flattened bamboo culms are used to cover the floor of the room and to make the walls and doors. The floor of both verandahs are made from either whole bamboo or longitudinal halves placed side by side and bound to the beam structure below the floor. A single log, which is notched, forms the short ladder at the front of the house.

Bamboo Reinforced mud wall:

Mud wall gives protection against heat and cold. Now a days mud walls are constructed by reinforcing these with quartered split bamboo culms properly treated with hot bitumen. Properly kneaded mud mixed with rice husk, cinder and a little lime and water are applied layer by layer keeping the bamboo grid in the center which is later plastered and smoothened and finally white washed.

An experimental house constructed in 1973:

Interesting observations made by Bipul Kumar Das on an experimental house constructed during 1973, at Guwahati, a part of Assam in India reveals that the condition of the bamboo strips that were used for 25 years inside the structure was good without any proper treatment. The bamboo strips were used for both the roof and wall construction. Bamboo used were not chemically treated but taken from the lot that were river transported. This proves that the bamboo promises a very long lasting period provided that the conditions are conducive.

An experimental house with bamboo strips constructed during 1973

Bamboo houses in southern parts of India:

Generally, the houses in these parts can be grouped into thatched and tiled houses. In both the types, bamboos are invariably used for making roof structure. In certain houses, especially thatched houses, in addition to the roof, bamboos are used for walls, windows, doors and even partitioning.

Thatched bamboo house:

The thatched bamboo houses are small in size. In Kerala state, the average plinth area of thatched house and the average plinth area per person are 39 m2 and 8 m2 respectively (P K Murlaeedhara et. Al. 1999). The corresponding figures for Karnataka are 31 m2 and 7 m2. The average plinth area of thatched houses was found to be higher in highland areas than in mid and lowland areas of both states, as bamboos are available at a low price in the highland areas. The basement of bamboo houses in Kerala and Karnataka is predominantly made of low quality materials like mud and sand and only in a few houses are brick and rubble used. This is attributed partly to the poor economic conditions and partly to its small size.

Many houses in the highland areas in Karnataka have bamboo reinforced mud walls. This structure is very cheap and lasts for more than ten years. Wood is the preferred material for windows and doors in the majority of the bamboo houses. The Roofs of all the selected houses are constructed with bamboo. Grass, straw and coconut leaves are used as thatching materials, of which the latter is used in the majority of the thatched houses in both the states. This may be due to the abundance of coconut trees and easy availability of thatching leaves from them.

Tiled Houses:

In Kerala, the average plinth area of the tiled house is 58 m2 and plinth area per person is 14 m2. Of the study conducted on a total sample in the State, tiled bamboo houses constitute only 8 per cent. Around 35 per cent of the total samples in Karnataka are tiled houses with an average plinth area of 72 m2. The average plinth area of the tiled houses in Karnataka varies between 82 m2 in highland areas and 51 m2 in lowland areas.

In Karnataka and Kerala, 80 to 85 percent of tiled houses have their basement made of brick. Wood is widely used for windows and doors in both the states. Bamboo is used as roof frame in all the sample houses that are taken for study. In highland areas, where very thick bamboos are available, they are used even as the main and lateral supporting beams. But in other areas, some houses have used wood or Casuarina poles as main or supporting poles.

Bamboo Composites

Bamboo boards and panels developed earlier at FRI and now perfected, demonstrated, standardized as well as taken to industrial level by IPIRTI have enormous potential in the building industry.

IPIRTI has developed cost effective technologies for manufacture of bamboo composites which have been commercialized. These technologies are not only environment friendly but also people friendly as they have immense employment generation potential particularly for women in the bamboo growing area. Use of bamboo composites will lead to reduction of pressure on non renewable building materials, reduce pollution and lead to substantial energy conservation. The Institute has brought out specification for all the three bamboo composites developed i.e. IS: 13958 Bamboo Mat Board for General Purpose, IS: 14588 Bamboo Mat Veneer Composite for General Purpose and IS:15476 Bamboo Mat Corrugated Sheet as roofing material. These products are well accepted in the market and there is a great demand.

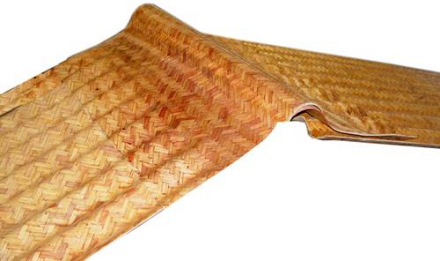

Bamboo mat board [BMB]: BMB is essentially a layered composite comprising several layers of woven mats of herringbone pattern, having excellent internal bond strength, and are resistant to decay, insects and termite attack. They have physical and mechanical properties on par with waterproof plywood and are fire resistant. Their mechanical properties depend upon the species of bamboo used for mat making, the weaving pattern and the adhesive used for bonding. BMB has high in-plane rigidity and hence high racking strength and is more flexible than equivalent plywood. This property of BMB can be advantageously used in many engineering applications.

Bamboo mat veneer composite [BMVC]: In BMVC, wood veneers are placed in between the layers of bamboo mats. The properties of BMVC depend on the type of construction in addition to the species of veneer and type of adhesive used. The strength of a panel made by plantation timber is substantially enhanced when made in combination with bamboo mats. BMVC can be used for structural applications similar to plywood.

Bamboo mat corrugated sheet [BMCS]: [BMTPC-IPIRTI TECHNOLOGY]

BMCS is made of four or more bamboo mats bonded with an adhesive and pressed in a specially designed sinusoidal platen dies. They have very high potential as eco-friendly roofing material. The load deflection curves of various corrugated roofing materials indicate the comparative advantage of BMCS over other corrugated materials. The load bearing capacity of BMCS is comparable to that of ACCS and CGI sheets and much superior to ACS. BMCS being light in weight possesses high resilience.

BMCS is water proof and resistant to decay, termites/insects and fire. The thermal conductivity of BMCS(0.1928 Kcal/m°c) is lower compared ACCS.(0.3422 Kcals/ m°c) and provides better thermal comforts compared to houses having ACCS or CGIS as roofs.

Bamboo Mat Ridge Cap (BMRC):

The size of the Bamboo mat ridge cap is 1.05 m x 0.43 m with a thickness between 3.5 to 3.7 mm. having a weight of 2.0 kg. Bamboo mat ridge cap is dimensionally stable and compatible with BMCS and suitable for a wide range of roofs.

IPIRTI-TRADA Bamboo Based Housing System

Bamboo based housing systems have very high potential for mass housing, housing in disaster prone areas and for earthquake resistant structures/houses and other applications. The low mass of the bamboo based building is an advantage under earthquake conditions as compared to masonry structures. The buildings constructed in bamboo using this method are able to withstand the highest levels of earthquake loading likely to be experienced in India. The test building of 2.7m2 resisted seven repetitions of a typical Zone 5 earthquake, the highest in India and equivalent to 7 on the Richter scale, as well as a replication of the notorious Japanese Kobe earthquake (Richter 7.8), without any damage whatsoever.

Characteristics of the Bamboo Based Housing System

The system has following unique characteristics:

- Affordability: Foundations are minimized, wall panels are non-load bearing and can be reduced in thickness, basic components like bamboo, binding wire, bolts, chicken mesh etc are inexpensive and available locally.

- Sustainability and environmental impact: Bamboo is available in commercial quantities using the established supply system. It is a renewable resource with a short rotation period and can be grown on degraded lands. The bamboo is treated using environment friendly preservatives. The usage of high energy embodied materials like cement steel is minimized.

- Cultural Acceptability: The system offers traditional materials in a modern engineering context. The result is homely with a feel of permanence.

- Durability and Safety: All bamboo components are effectively treated with safe preservatives to give extended life, the structure is engineered to resist wind and earthquake forces and other imposed loads.

- Improved jointing techniques: nailing of bamboo is eliminated therefore splitting is prevented. Wiring, bolting and strapping provides the positive connections.

- Modular construction: suited to either prefabrication or fabrication in situ i.e., all components like infill grids, roof trusses are designed to be prefabricated or prepared on site.

- Ease of Assembly: only basic carpentry and masonry tools and skills are required to undertake the construction.

Differences from Conventional Bamboo construction practices

The IPIRTI -TRADA Bamboo Housing system differs significantly from conventional bamboo construction practices in many ways viz. –

(a) Use of round bamboo as columns, rafters and trusses as main load bearing element,

(b) Use of split bamboo grids/chicken mesh and plastered with cement mortar to act as shear walls for transmitting wind loads and to provide overall stability to the structure,

(c) Application of appropriate preservative treatment to bamboo depending on the degree of hazard and service conditions,

(d) Use of BMB as gussets in combination with mild steel bolts for load bearing joints in roofing structure, and

(e) Use of BMCS as roof cladding.

Construction Techniques

Treatment of components with preservatives

Since bamboo is prone to attacking several insect pests, treatment of round/split bamboo used as such in housing through appropriate methods is now essential.

Bamboo columns can be treated either by internodal injection with creosote or by the Boucherie process using Boron. This process can be used for fresh green bamboo only. Portions of bamboo columns which are in direct contact with soil and below the soil can be treated by hot and cold creosote treatment. In other words, no elaborate equipment, like a pressure impregnation plant is required for treatment. Only storage tanks/sheet metal tanks are enough for dipping and hot or cold treatment.

Split bamboo slivers used for infill wall panels plastered with cement mortar can be treated by diffusion process using boron chemicals. This technique has been found to be very effective.

Trusses, rafters and purlins, whether made from whole culm or split culms are protected from direct wetting and can therefore be treated using the boron dip diffusion method.

Foundation

The bamboo building system developed by IPIRTI-TRADA is very light compared to usual trial/masonry structures. As such extensive foundation work is not required and is limited to individual footings 400 x 400 x 600 mm deep for each bamboo column.

Columns

Treated bamboo culms 80 – 100 mm dia. and a wall thickness of 10 – 12 mm, spaced at an interval of 1.2M and set in concrete footings provide the basic load bearing framework for the building. A wooden wall plate 100 x 40 mm sawn plantation timber is fixed to the top of the columns by skewering into wooden inserts that ties the columns at top and distribute dead loads due to weight of trusses, purlins and sheet roofing. The columns are pierced by steel dowels at 150mm centers to provide connection to the bamboo grid infill.

Plinth and Flooring

The Plinth consists of a few courses of concrete block/size stone/brick raised to a height of 40 – 45 cms and filled with compacted earth and topped with brick bats and skidded with 20 mm of cement mortar.

Wall infill panels

The wall infill is non-load bearing and comprises a grid of split bamboo (19 mm x 9 mm) tied together with MS binding wire to form a 150 mm x 150 mm grid. The grid is tied to steel dowels passing through the columns. Chicken wire mesh is fixed on the outside face of the grid. A 1:3 mix cement mortar is applied on both sides of the grid to a finished thickness of about 50 mm. The same principle can be extended to the construction of gables. Alternatively gables may be formed with bamboo mat boards.

Although the walls are basically non-load bearing and only 5 cm thick, they are capable of withstanding racking loads due to wind normally prevailing in India and is taken to be 100 kg/m2. A wall of 2.4M height showed no sign of failure with racking deflection of only 0.35 mm when a racking load of 500 kg was applied at the top. The walls are also capable of withstanding soft and light body impact and hard body impact tests as per British Standards. It is also capable of resisting shocks due to a 30 kg filled spherical leather bag as per Indian Standards without damage.

Hence, bamboo reinforced cement mortar walls for a maximum height of 2.4M is capable of transmitting lateral loads due to wind to the bamboo columns and in turn to the foundation.

Roof structure

Traditionally timber trusses or rafter-purlins have been in vogue for sloping roofs from time immemorial. Bamboo trusses offer a good substitute for supporting roof loads and transmitting them to the foundation through columns. Bamboo trusses are fabricated using culms having an outer diameter of 75-100 mm. When the top and bottom chords and strut members are properly jointed by suitable fastening devices, a truss can resist compressive and tensile forces conglomerately and as such act as a stronger supporting component even in earthquakes compared to rafter-purlin system The roof comprises of 300 pitch trussed rafters (collared trusses] spaced at 1.2M fixed to the wall plate (over columns) using purpose made steel strips. The truss members are 80 – 100 mm dia. bamboo and joints are gusseted using 6 mm BMB and 8 mm dia. bolts. The trusses are designed for a maximum dead load of 10 kg/m2 due to purlins and roof covering and a live load of 40 kg/m2. The bamboo mat gusset provides excellent connection between chord and collared members and detailed tests have shown that joints have failed due to bearing of BMB and not due to shearing or splitting of bamboo with enough factor of safety.

Roof Covering

Bamboo Mat Corrugated Sheets currently developed and produced at Institute offers a convenient alternative to existing roof cladding materials like asbestos cement, CGS. 3mm BMCS with a pitch of 7.5 cm and depth of 3 cms has a load bearing capacity of 5 N/mm for a span of 1M. These sheets have been used for the houses and fixed to 25 mm dia. purlins spaced at 1M using standard J-bolts. Purlins are tied to the trussed rafters using MS bolts and binding wire.

Door and Windows

Frames are made of 75 x 60 mm sawn plantation timber like silver oak and shutters consists of single skinned BMB infill panels stiffened with silver oak rails and styles. Door and window frames are tied to the grids through nails driven into the outer perimeter of door and window frames as fixing points.

Finishing

Infill walls can be finished outside either with cement paint or usual lime wash inside finished with distemper. Exposed bamboo and wood work have been successfully and economically finished with semi transparent CNSL based varnish. Interior ceiling also can be finished with colourless cardinal based varnish. Alternatively, bamboo and wood work would have also been finished with synthetic enamel paint available in the market.

Bamboo Trusses

Trusses offer a number of advantages over traditional forms of construction, including more economic and efficient use of materials, the ability to span large distances, the use of shorter components (counteracting effects of bow, crook and taper) and the use of prefabrication

The previous works that have been carried out in this area are limited to traditional joinery (using bamboo/jute rope for connections). Limitations of these studies are relative weakness of the joints and bamboo in compression perpendicular to its length. In addition, much of the deflection of a loaded truss has been found to be due to deformation at the joints. Traditionally timber trusses or rafter-purlins have been in vogue for sloping roofs from time immemorial. Bamboo trusses offer a good substitute for supporting roof loads and transmitting them to the foundation through columns. Bamboo trusses are fabricated using culms having an outer diameter of 75-100 mm. Bamboo trusses supporting the roof are shown in Figure. 2 and bamboo truss while testing is shown in Fig. 3.

Conclusion

Development of bamboo structures depends upon availability of graded & standardized raw material; Access to design information like standards & codes, design procedures to engineers/ Architects; Availability of eco friendly preservatives and preservative facilities; trained man power in bamboo carpentry & joining methods; Participation of NGO’s and Government in encouraging wider use of bamboo building; development of standard designs and Do-it-yourself kits.

About the author;

Dr. Jagadish Vengala is currently a National Governing Council Member, of the Bamboo Society of India. He works as Convenor, Institute Innovation Council and Associate Professor, Department of Civil Engineering, PVP Siddhartha Institute of Technology, Vijayawada. He was a former scientist at IPIRTI, Bangalore.

He completed his Ph.D. in “Seismic Response Study of bamboo-based Constructions” from VTU, Belgaum, in 2015, for which he was conferred with INAE Innovative PhD Thesis by the Indian National Academy of Engineering (INAE). He is the recipient of the 5th CIDC Viswakarma Award – Under the category of Achievement Award for Scientist for the year 2013 from the Construction Industry Development Council (CIDC), established by the Planning Commission, Government of India and Construction Industry for the work carried out in the area of bamboo housing.

He also visited the USA to avail BOYSCAST Fellowship by DST, Government of INDIA, and worked under Prof. John Vande Lindt, at Colorado State University, USA to study the seismic behaviour of a bamboo-based housing system from March to September 2008. He delivered over 100 Important Keynote sessions on bamboo in more than 16 states.

Reference

- Rajput, S.S., Gupta, V.K. and Sharma S.D. Classification and grading of bamboos for structural utilisation and their safe working stresses, Journal of Timber Development Association(India), 38(2):19-32

- Sanyal, S.N., Gulati, A.S., and Khanduri, A.K. Strength properties and uses of bamboos A review, Indian Forester 114(10) : 637-649.

- National Building Code of India

- Janssen, Jules. “Designing and Building with Bamboo.” Technical University of Eindhoven

- Bipul kumar das, ‘Bamboo in the field of construction in North east India’, Technical Report No.1, CBTC.

- H G Reddy, H N Jagadeesh and K Shyamasundar “Testing of a bamboo-based wall system” DFID KAR project R7140, Report Number: TEO/F98002/05.

- IPIRTI Research Report, “Bamboo Housing Construction Techniques, Do-it-Yourself”

- ‘Building with sustainable forest products’ The Structural Engineer PP. V81/1.

- ‘IPIRTI, Status of bamboo housing technology developed at IPIRTI, IPIRTI Miscellaneous Report, (13pp.)

- IS 6874, Methods of test for round bamboos, Bureau of Indian Standards, New Delhi

- IS 8242, Methods of tests for split bamboos, Bureau of Indian Standards, New Delhi.

- IS 9096, Code of practice for preservation of bamboos for structural purposes, Bureau of Indian Standards, New Delhi.

- IS 13958, Specification for bamboo mat board for general purposes, Bureau of Indian Standards, New Delhi.

- IS 14588, Specification for bamboo mat veneer composites for general purposes, Bureau of Indian Standards, New Delhi.

- IS 15476, Bamboo Mat Corrugated Sheets – Specification, Bureau of Indian Standards, New Delhi.

- Bansal, A.K., Pandey, C.N. and Nath, S.K. “Bamboo Composites- IPIRTI Technologies”, IPIRTI, Bangalore.

- K. Shyamasundar and Jagadish Vengala ‘Promotion of bamboo housing system & recent developments’, World Bamboo and Rattan, PP 5-10, Vol.4 No.2

- J.Vengala, H.N. Jagadeesh & C.N. Pandey “Development of Bamboo structures in India” PP 51-63, Modern Bamboo structures – Xiao et al.,(eds) © Taylor & Francis group, London, ISBN 978-0-415-47597-6

- Jagadish Vengala and S. Ragunath” “Sustainable Bamboo Housing for the Earthquake Prone Areas ” IOP Conference Series: Materials Science and Engineering, Vol. 955.

- Jagadish Vengala, B. N. Mohanty and S. Raghunath “Seismic performance of Bamboo housing– an overview” Proceedings of 10th World Bamboo Congress, Korea, PP 389-407, ISBN: 978-1-5108-1326-7, ISSN: 2150-1165

- Jagadish Vengala, C N Pandey, “ Construction Techniques of Bamboo based Housing” pp. 154-165, Proceedings of the National Seminar on Recent Advances in Bamboo Propagation, Management and Utilization – Pankaj K. Aggarwal et al., organised by IWST, Bangalore, ICFRE, Dehradun, ISBN:81-89650-25-4