Picture this: you’re driving down a familiar road, the hum of tyres harmonising with the rhythm of the journey. But suddenly, you feel a jolt as your vehicle dips into an unexpected pothole. As you navigate around this pavement imperfection, have you ever wondered what causes such road distresses to emerge so unannounced? The answers lie within the intricate layers that make up our roads – the subgrade, sub-base, base course, and surface course.

What is road pavement failure?

Road pavement failure refers to the deterioration and degradation of a road’s surface and underlying layers, resulting in compromised structural integrity and functionality. It encompasses various distresses and defects that make the road unsafe or unsuitable for smooth transportation.

Signs of road pavement failure;

Signs of road pavement failure can manifest in various ways, and recognizing these signs is essential to address issues before they escalate. Here are some common signs of road pavement failure:

- Potholes: Depressions or holes in the pavement surface caused by the disintegration of the asphalt or other road materials. Potholes are typically formed due to water infiltration and traffic loads.

- Cracks: Long, narrow openings in the pavement surface. Different types of cracks, such as transverse, longitudinal, and block cracks, can indicate distress in the pavement layers.

- Rutting: Visible wheel paths or grooves in the pavement caused by repetitive heavy traffic loads. Rutting can lead to poor drainage and pavement instability.

- Alligator Cracking: A pattern of interconnected cracks resembling the scales of an alligator’s skin. This type of cracking indicates structural failure and distress in the pavement layers.

- Ravelling: Detachment of aggregate particles from the surface of the pavement, leaving a rough and loose texture. Raveling is usually a result of poor pavement material or inadequate construction.

- Bleeding or Flushing: The presence of a thin layer of asphalt on the pavement surface caused by excess bitumen rising to the surface. This can lead to reduced skid resistance and hazardous driving conditions.

- Depressions or Settlements: Sunken areas in the pavement surface, often caused by inadequate support from the subgrade or sub-base layers.

- Deteriorating Joints: Cracks or separations between adjacent pavement sections or slabs. Failing to maintain or repair joints can lead to further pavement degradation.

- Faded Markings: Worn-out pavement markings and road signs due to weathering and traffic wear.

- Uneven Surfaces: Irregularities in the road surface, including bumps and waves, which can cause discomfort to drivers and affect vehicle stability.

If any of these signs are observed, it is essential to conduct a thorough pavement inspection and assessment to determine the extent of the failure and plan for appropriate repairs or rehabilitation. Early detection and timely action can help prevent further damage and ensure the safety and longevity of the road infrastructure.

Causes of road pavement failure; Road pavement layer is the culprit

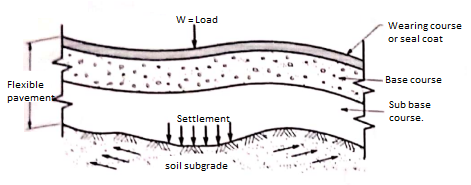

Road pavement failure occurs when one or more pavement layers become compromised, leading to distresses and defects that affect the overall structural integrity of the road.When one or more layers fail, it can create a domino effect, as the weakened layers are unable to withstand the stresses imposed by traffic loads and environmental factors. The failure of one layer can result in excessive load transfer to the adjacent layers, causing further distress and accelerating the deterioration process.

Discussed below are different types of road pavement failure that can occur in each layer of the pavement.

1. Subgrade Layer:

The subgrade is the natural soil or compacted material beneath the pavement layers, providing support to the pavement structure.

– Types of Failure:

- Subgrade Rutting: Excessive traffic loads and poor drainage can cause permanent deformations or rutting in the subgrade, leading to surface irregularities and reduced stability.

- Subgrade Settlement: Inadequate compaction during construction or weak soil conditions can result in subgrade settlement, causing depressions on the pavement surface.

– Causes:

- Inadequate Soil Strength: Weak subgrade soils unable to withstand traffic loads lead to settlement and deformation.

- Excessive Moisture: Poor drainage or prolonged exposure to water softens the subgrade, reducing its load-bearing capacity.

- Poor Compaction: Inadequate compaction during construction results in a weak and unstable subgrade.

2. Sub-base Layer:

The sub-base is a layer of material placed above the subgrade and below the base course, providing additional support to distribute loads evenly.

– Types of Failure:

- Sub-base Rutting: Excessive traffic loads, inadequate thickness, or poor material quality can cause rutting in the sub-base layer.

- Sub-base Degradation: Poor quality materials or contamination can lead to sub-base degradation, reducing its load-bearing capacity.

– Causes:

- Inadequate Thickness: A thin sub-base layer may not adequately distribute loads, leading to localized failures.

- Improper Material Selection: Using unsuitable or low-quality materials compromises its load-bearing capacity.

- Poor Compaction: Insufficient compaction results in reduced stability and support for the overlying layers.

3. Base Course Layer:

The base course is the layer above the sub-base, providing further load-bearing capacity and distributing loads from the surface course.

– Types of Failure:

- Base Course Rutting: Inadequate thickness, poor material quality, or excessive traffic loads can lead to rutting in the base course layer.

- Base Course Cracking: Insufficient thickness or poor material properties can cause cracking in the base course.

– Causes:

- Insufficient Thickness: A thin base course may not handle traffic loads, leading to structural failure.

- Poor Material Quality: Low-quality materials may deteriorate faster under traffic and environmental stresses.

- Environmental Factors: Freeze-thaw cycles and moisture infiltration can weaken the base course.

4. Surface Course Layer:

The surface course is the topmost layer of the pavement visible to road users, providing smoothness and skid resistance.

– Types of Failure:

- Surface Cracking: Fatigue from traffic loads, environmental stresses, or poor mix design can cause cracking in the surface course.

- Surface Distress: Surface distress may include potholes, raveling, bleeding, flushing, and other surface defects.

– Causes:

- Repetitive Loading: Fatigue from traffic loads causes surface cracks and distress.

- Environmental Stresses: Extreme weather conditions, UV radiation, and moisture deteriorate the surface course.

- Inadequate Thickness: A thin surface course wears out faster and may not withstand traffic loads.

- Poor Mix Design: Improper asphalt or concrete mix design affects durability and performance.

5. Joint and Crack Failures:

Joints and cracks are critical elements in pavement design that accommodate thermal expansion and contraction.

– Types of Failure:

- Unsealed Cracks and Joints: Unsealed cracks and joints allow water infiltration, leading to subgrade saturation and structural damage.

- Faulting: Differential settlement or movement at joints can cause faulting, creating uneven surfaces and roughness.

– Causes:

- Lack of Maintenance: Failing to seal cracks and joints allows water to penetrate, causing further pavement distress.

- Inadequate Design or Construction: Poor joint design or construction practices can lead to premature failure and faulting.

- Addressing these different types of road pavement failure requires specific strategies tailored to each layer’s characteristics and underlying causes.

Mitigating road pavement failure

Addressing different types of road pavement failure in each layer requires specific strategies tailored to the characteristics and causes of the distresses. Here’s how to address various types of pavement failure in each layer:

1. Subgrade Layer:

– Subgrade Rutting:

- Improve Drainage: Proper slope design and installation of subsurface drains can prevent excessive moisture from weakening the subgrade.

- Compaction and Stabilization: Ensure the subgrade is adequately compacted during construction, and consider using stabilizing additives like lime or cement to enhance its load-bearing capacity.

– Subgrade Settlement:

- Compaction: If subgrade settlement is due to inadequate compaction, reinforce the subgrade by recompacting the affected area during maintenance or rehabilitation.

2. Sub-base Layer:

– Sub-base Rutting:

- Improve Material Quality: Use high-quality materials suitable for the intended purpose and traffic loads in constructing the sub-base.

- Compaction Control: Ensure proper compaction during construction to achieve the desired density and strength.

– Sub-base Degradation:

- Contamination Management: If sub-base degradation is due to contamination, remove and replace the affected material with suitable material during rehabilitation.

3. Base Course Layer:

– Base Course Rutting:

- Design Considerations: Ensure the base course is designed with adequate thickness and suitable materials to withstand expected traffic loads and environmental conditions.

- High-Quality Materials: Use durable and high-strength materials for the base course construction.

– Base Course Cracking:

- Mix Design: Use appropriate mix design with suitable materials to resist expected traffic loads and environmental conditions.

- Regular Maintenance: Conduct regular inspections and perform timely repairs, such as crack sealing and patching, to prevent base course cracking.

4. Surface Course Layer:

– Surface Cracking:

- Mix Design: Use appropriate mix design with suitable materials to resist expected traffic loads and environmental conditions.

- Regular Maintenance: Conduct regular inspections and perform timely repairs, such as crack sealing and patching, to prevent surface cracking.

– Surface Distress (e.g., Potholes, Raveling, Bleeding, Flushing):

- Timely Repairs: Address identified surface distresses promptly with appropriate repair techniques during regular maintenance to prevent further deterioration.

5. Joint and Crack Failures:

– Unsealed Cracks and Joints:

- Crack Sealing and Joint Maintenance: Regularly seal cracks and maintain joints to prevent water infiltration and subsequent structural damage.

– Faulting:

- Joint Repair: Address differential settlement or movement at joints by repairing or rehabilitating the affected joints during maintenance or rehabilitation.

General Measures for All Layers:

- Regular Inspection: Implement a routine inspection program to identify distresses and defects in the pavement layers promptly.

- Data-Driven Decision Making: Use data from inspections, performance evaluations, and tests to make informed decisions about maintenance and rehabilitation strategies.

- Quality Construction: Ensure proper construction practices are followed during the initial construction phase, including adequate compaction and material selection.

- Effective Drainage: Implement proper drainage systems to prevent water from accumulating and weakening the pavement layers.

By applying these specific strategies, road authorities and engineers can effectively address different types of road pavement failure in each layer, prolong the life of the pavement, reduce maintenance costs, and ensure a safe and efficient transportation network.

Importance of addressing road pavement failure in India

Addressing road pavement failure in India is crucial for several reasons. First and foremost, it affects public safety as deteriorating roads can lead to accidents and injuries. Secondly, it impacts the economy by increasing vehicle maintenance costs and causing transportation delays, hindering trade and productivity. Moreover, improving road infrastructure can boost tourism and overall economic development. Additionally, it plays a vital role in reducing air pollution and carbon emissions by promoting efficient transportation. By addressing pavement failures, India can enhance its overall infrastructure, connectivity, and quality of life for its citizens.

Conclusion

As we navigate the labyrinth of our modern roadways, let us not forget the tireless battles beneath our wheels. Road pavement failure is a reminder that our infrastructure is an ever-evolving canvas, one that requires constant care, attention, and ingenuity to keep us connected and secure. In our pursuit of smoother, safer journeys, we must never underestimate the complexity of the world beneath our tyres.