Today, power tools are so ubiquitous that most of us take them for granted. However, the reality is that these tools have not always enjoyed a pervasive stature. Prior to their invention, in the 1800s, ancient people didn’t have efficient tools. It has gone through evolution. Power tools include a wide range of devices for fabrication, assembly, construction, and repair. It is actuated by an additional power source and mechanism other than the solely manual labour used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed air are also commonly used.

Construction tools are used to improve work efficiency and reduce labor costs. If you want to reduce overall construction costs which include labor and material then you have to avail construction estimating services.

Power Tools are basically the type of tools that are powered or run by electricity. This type of tool is used for a variety of purposes which include plumbing, electricity, construction and industrial jobs. These Power Tools are known to have multiple users in both homes and industrial establishments. In comparison to other types of tool powered tools have many added advantages. Power tools are classified as either stationary or portable, where portable means hand-held. Portable power tools have obvious advantages in mobility. Portable power tools have obvious advantages in mobility. Stationary power tools, however, often have advantages in speed and precision.

It’s important to keep in mind that many tools can be quite dangerous when used incorrectly or without the right amount of knowledge or skill. Even with proper training, even the most expert tradesmen can still have an accident. A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labour used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed air.

Trends in power tools

Cordless power tools are gaining extensive acceptance and implementation in both home and workplace. Cordless power tools include a wide range of battery-powered tools, such as hammer drills, impact wrenches, and circular saws, as well as nailers and staplers. These sorts of cordless tools are ideal for sanding, welding, metalworking, cutting, and other applications. This is propelling the market growth. However, the high maintenance cost along with regular price fluctuations in raw materials of power tools are limiting the growth of the power tools market. In terms of tool type, the power tools market is segmented into drilling and fastening tools., demolition tools, sawing and cutting tools, material removal tools, routing tools, air-powered tools and others. Based on mode of operation, the power tools market is segmented into electric, pneumatic, and hydraulic. Companies have been implementing research and development (R&D) efforts in order to bolster tool strength and life span.

Advantages of power tools.

It is known to have multiple users in both homes and industrial establishments. In comparison to other types of tool powered tools have many added advantages. Some of them are given below.

- It is most effective for repair and construction tasks. That’s because you can get your work done without causing much disruption a disturbance at the work site

- It is not restricted in construction works only, it is used in the garden, for housework tasks such as cooking, cleaning, and around the house for purposes of driving (fasteners), drilling, cutting, shaping, sanding, grinding, routing, polishing, painting, heating and more.

- It is impossible to drive screws or nails into concrete with hand tools, but with the right tools, concrete anchors can be driven into anchor walls to concrete floors

- With the help of these tools, you can get your work done at high speed. This is especially important for all those time-consuming tasks that may take you hours to complete

- It is much more powerful than hand tools and have motors, a power source, battery and electricity, on which they run

- Using itis safer as they have controlled range of noise and vibration, which are specified according to each product

- Getting a perfect finish is not possible with a handheld tool, but a power tool helps in giving the desired finish

- With it, you can have a clear estimation of capacity, overall and power input which simplifies the job for workers

- Working with power tools may also get your work done faster. This is one of the main reasons that workers these days prefer to use power tools instead of hand tools so that they can save their time. This way the workers can also focus on the quality of their work rather than wasting that time

- Effective for repair and construction tasks. That’s because you can get your work done without causing much disruption at the work site. The use of power tools ensures that the work is done hassle free

- By considering these advantages, you’ll better understand the importance of power tools in construction. Moreover, it‘d be best to source thesetools from reliable manufacturers and merchants to ensure high-quality and effective products.

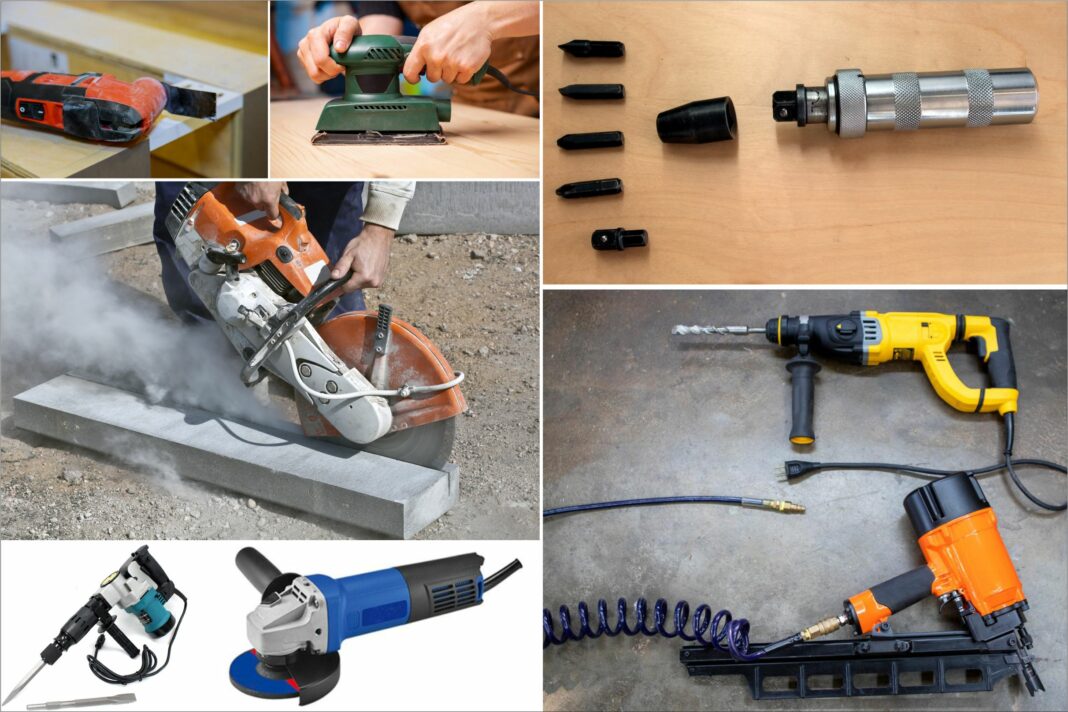

Different types of power tools

Power tools have long been convenient resources for various industries, aiding workers from all sorts of disciplines. With special features like electric motors, power tools help eliminate strenuous, manual labor. In what had begun as a poor decade in terms of power tool sales, financial stability within the construction and automotive industries is giving way to new innovations in the tool market. Different types are discussed below.

Cordless Jigsaw

A cordless jigsaw is a small power tool that is used to cut curved lines on a wooden piece. While regular saws are meant for cutting straight lines on wooden materials, a cordless jigsaw is used for curving out complicated and curved lines. Depending on the height and tooth count of the blade you attach, you can use a jigsaw blade for multiple purposes. From wooden pieces to even metal materials, a cordless jigsaw can be used to make cuts on a variety of materials. The basic format of the jigsaw is the blade moves upward and downwards to make the cuts. With the speed control option, you can control how fast the blade moves while you are cutting.

Cordless mini circular saw

A circular saw is a power tool that features a toothed disc blade in the middle. The disc blade rotates on its axis and eventually cuts through the wooden piece you are applying it on. From plastic to wood and even metal – this power saw can cut almost any materials that come in front of it. As you can tell, there are two versions of a circular saw – a regular one and a mini one. While the regular one can be used to cut heavy-duty materials, a mini circular saw can be used for cutting laminated wood or softwood for household purposes.

Cordless Drill

A cordless drill is actually what you know as a drill machine from the past. It’s just got wireless. This battery-powered electric drill can be used to make holes in different parts of a wooden structure. It comes with a number of attachments on the front that are known as bits. Bits have different sizes and diameters to punch different sizes of holes. Another benefit that you can get from a cordless drill is to fasten screws and nails. Using the proper drill bit, you can use it to fasten any screw on any surface, just like that.

Electric Demolition Jack Hammer

The jackhammer is used when you are working on construction sites, you need to break solid stones or concrete bricks at times. An electric demolition jackhammer is the only pal you have that makes the job easy. It comes with some attachment known as a chisel. Different chisels come in different shapes – some come in bull-point, some come in a flat design. Depending on what you are breaking apart, you need to attach the related chisel to the hammer.

Nail Gun

An electric cordless nail gun is the latest development and upgrade to the age old hammer. The nail gun is used to nail nails on wooden models and structures. All you need to do, is simply point the gun head towards the point you need to nail and pull the trigger. Just like a typical gun, it will fire a nail at the target area and literally nail it.

Concrete Saw

A Concrete Saw is an advancement from the regular circular saw we had seen earlier. It’s designed the same way, but a bit larger in size and more powerful. The rotating disc blade on the saw is quite powerful to cut through concrete blocks and bricks. So, basically, a concrete saw is a mixture of a circular saw and a demolition jackhammer. It looks like a circular saw but acts like a demolition hammer.

Reciprocating Saw

Contrary to a jigsaw, a reciprocating saw has a blade at the front of it. The blade acts the same way as a jigsaw, but the movement of it is back and forth. It’s basically a jigsaw held at a 90-degree angle. This saw is mainly used in cutting down the wood pieces and other materials where you can’t put your hands in. Other than construction sites, a reciprocating saw is used to cut windows and other parts of places where emergency rescue is due.

Side Grinder

Side grinders are a handheld power tool which cut, grind, and polish metal and non-metal objects. A compressed tool, petrol engine, or an electric motor is required to power these tools. They are available in both corded and cordless forms and can be used for cutting and smoothing out hard edges and materials like stone, metal, wood, etc.

Biscuit Joiner

Often labelled as a plate joiner, biscuit joiners are used for joining two pieces of wood together. A plate joiner consists of a rounded saw blade that helps cut small-sized holes to join wood pieces.

The compressed biscuit is then glued together to stay apiece. Depending on the project, you can use the compressed biscuit where you need them. Generally, it is used in joining sheet goods like plywood, particleboard, and medium-density fiberboard.

Power Sanders

Sanding is a crucial aspect of carpentry as it removes dents, mill marks, and other flaws from an object. Many types of sanders are used to carry out this purpose; the most useful and largest of all is a belt sander. It features an electric motor, a pair of cylinders, and sandpapers, helping in trimming and finishing wooden objects. They are also used for the purpose of smoothing rough surfaces, leveling out and shaping objects.

Orbital Sander

Orbital sanders are a specialized tool that features a vibrant sanding surface. As the name implies, this sander is circular in shape and functions in a rotating motion. The tool operates by an electric motor which runs at a super high speed. The sanding disk spins in a circular way, making it easier to get into edges and corners. Orbital sanders are used for a variety of projects, especially those that need a light sanding. It helps prepare a surface for painting, refinishing, or sealing. The finishing of a surface is not possible without orbital sanders which are a part of the reason why they are also called “finish sanders”.

Oscillating Multi-Tool

Multi-tools have interchangeable heads so that they can be used for many kinds of applications. An oscillating multi-tool can be used for trimming, sanding, pipe cutting, paint removal—you name it. Many oscillating tools come with a variety of attachments including, wood blades, metal blades, sanding pads and adapters.

Angle Grinder

The angle grinder is a spinning disc that moves at extremely high RPMs. Angle grinders are used for many different applications–it all depends on the disc you choose. Buffering discs can polish metals. A grinding wheel is used for cutting metals or sharpening metal edges. Dry-cut diamond wheels are used for cutting tiles, ceramics and other masonry substrates.

Impact Driver

These tools are made to drive screws quickly and efficiently even through the toughest of materials. Impact drivers use a hammer-like gear that adds torque through the driver’s rotation; this is similar to a hammer drill but with the extra force being rotational rather than linear. They also tend to be smaller, lighter and require less effort from the user, so they are ideal for contractors who spend most of the day with a drill in their hands.

Pneumatic Tools

Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders. There are several dangers associated with the use of pneumatic tools. First and foremost is the danger of getting hit by one of the tool’s attachments or by some kind of fastener the worker is using with the tool. Pneumatic tools must be checked to see that the tools are fastened securely to the air hose to prevent them from becoming disconnected. A short wire or positive locking device attaching the air hose to the tool must also be used and will serve as an added safeguard. If an air h

Conclusion

Power tools are primarily used to cut, wrench, saw drill and polish materials. The growing impetus of the global power tools market is attributed to factors such as growing application of power tools in the construction industry and rising adoption of cordless power tools globally. You can convert JPG to PDF with PDF Software .With constant developments in the construction industry, the demand for construction machinery and advanced tools & equipment has increased. Appropriate personal protective equipment such as safety coveralls, goggles, and gloves must be worn to protect against hazards that may be encountered while using power tools. Power tools must be fitted with guards and safety switches; they are extremely hazardous when used improperly. You can also convert JPG to PDF with PDF Software from PDF4sure.You can Protect PDF Documents with yabbra.