Construction relies on a diverse range of handheld or powered tools used for concrete waterproofing, flooring, repairing, and maintaining structures. These tools play an important role in enhancing efficiency, precision, and safety, enabling construction workers to complete tasks quickly and accurately, ensuring work quality. They serve various purposes, from applying waterproofing materials precisely to crafting perfectly installed floors, ensuring structural accuracy, and maintaining concrete quality. In this article, we will explore different types of tools vital for waterproofing and flooring.

Waterproofing tools;

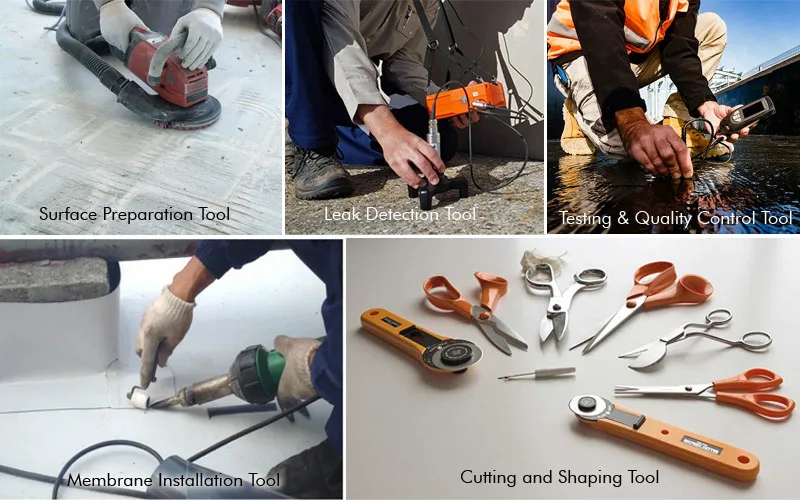

Waterproofing is a crucial process in construction to prevent water infiltration and protect structures from water damage. Various tools and materials are used in waterproofing applications. Here’s an overview of different tools commonly used for waterproofing:

1. Surface Preparation Tools:

- Wire Brushes: Used to remove loose debris, rust, and contaminants from surfaces. This prepares the surface for proper adhesion of waterproofing materials.

- Scrapers: Comes in various shapes and sizes and are used to remove old paint, coatings, or adhesives from surfaces. They help create a clean, smooth substrate.

- Grinders: Equipped with abrasive discs or wheels are used to level uneven surfaces, remove surface imperfections, and provide a clean, textured surface for waterproofing.

- Pressure Washers: Used to clean surfaces by blasting away dirt, grime, and loose material. They are effective for preparing large areas for waterproofing.

2. Application Tools:

- Rollers: Come in different nap lengths and are used to apply liquid waterproofing coatings evenly. They are commonly used on horizontal and vertical surfaces.

- Brushes: Various types (stiff or soft) are used for applying coatings to corners, edges, and irregular surfaces that rollers cannot reach.

- Trowels: Made of steel or plastic, are used for spreading and smoothing cementitious waterproofing compounds such as mortar or render.

- Caulking Gun: Used for applying waterproof sealants or caulks to joints, cracks, and gaps. This helps prevent water penetration in specific areas.

- Pressure Sprayers: Used to apply waterproofing coatings or sealants to large surfaces such as roofs or decks. They typically come with a hose and a spray gun, and they use compressed air to apply the coating evenly.

- Power Mixers: Used to mix waterproofing coatings or sealants quickly and efficiently. They come in various sizes and power levels, and they can be used with different types of mixing attachments.

3. Leak Detection Tools:

- Moisture Meters: Handheld devices measure moisture levels in materials like wood, concrete, or insulation. They help identify areas prone to leaks or dampness.

- Infrared Thermography Cameras: Detect temperature variations that may indicate hidden moisture or water leaks. They are particularly useful for identifying leaks behind walls.

- Ultrasonic Leak Detectors: Use sound waves to locate leaks by detecting the high-frequency noise produced by escaping water. They are useful for finding hidden leaks behind walls or within structures.

4. Membrane Installation Tools:

- Hot Air Guns: Used for heat welding seams in thermoplastic membranes like PVC or TPO. They ensure a watertight seal at seam connections.

- Hot Wedge Welders: Designed for fusing thermoplastic membranes together. They use a heated wedge to create a strong, waterproof bond.

- Seam Rollers: Used to press down and eliminate air bubbles or wrinkles in membranes, ensuring a secure and uniform bond.

5. Testing and Quality Control Tools:

- Hygrometers: Measure humidity levels in structures to assess potential moisture-related issues that may affect waterproofing.

- Pull-Off Testers: Assess the adhesion strength of coatings and membranes to surfaces, ensuring they adhere properly and won’t fail prematurely.

6. Safety Tools:

- Protective Clothing: Includes gloves, suits, and boots to shield workers from potential hazards.

- Respirators: Essential to protect against fumes, dust, and chemical exposure.

- Safety Goggles: Protect the eyes from splashes, fumes, and debris generated during waterproofing tasks.

7. Cutting and Shaping Tools:

- Utility Knives: Essential for precise cutting of membranes, flashings, or other materials during waterproofing projects.

- Scissors: Offer precision in cutting membranes and flashings with accuracy and ease.

- Saws: Depending on the project’s requirements, circular saws, reciprocating saws, or jigsaws may be used for cutting various materials like wood, plastic, or metal during waterproofing tasks.

- Crack Chasers: Designed to cut and widen cracks in concrete surfaces, preparing them for sealing and creating a waterproof barrier.

8. Accessories :

- Sealant Guns: Handheld devices used to apply sealants and adhesives, sealing joints and gaps in structures to prevent water infiltration.

- Backing Rods: Foam or synthetic rods are placed in joints before sealing to provide support and control the depth of sealant application.

- Caulk and Sealant Tubes: Ready-to-use cartridges contain waterproofing sealants, making them convenient for various applications like sealing joints, cracks, or gaps.

- Crack Injection Kits: Used to fill and seal cracks in concrete or masonry structures. They typically include epoxy or polyurethane injection materials and tools.

Flooring tools

Flooring tools play an important role in achieving professional and precise results when installing or maintaining various types of flooring materials. An overview of different types of flooring tools are given below.

1. Measuring and Layout Tools:

- Tape Measure: A flexible ruler used to measure the length and width of the flooring area accurately.

- Chalk Line: A tool for creating straight and precise guidelines on the floor surface.

- Carpenter’s Square: A right-angled tool for ensuring accurate 90-degree corners and straight cuts.

2. Cutting Tools:

- Utility Knife: A versatile cutting tool used for trimming and cutting various flooring materials like vinyl, carpet, and underlayment.

- Tile Cutter: Specifically designed for cutting ceramic, porcelain, and other types of tiles.

- Jigsaw: Ideal for making intricate cuts in wood, laminate, and engineered flooring.

3. Installation Tools:

- Floor Nailer/Stapler: Used to fasten hardwood and engineered wood flooring to the subfloor securely.

- Tapping Block: Protects the edges of flooring during installation and helps to tap boards into place.

- Flooring Spacers: Maintain consistent expansion gaps between flooring planks.

4. Adhesive and Fastening Tools:

- Adhesive Trowel: Used to apply adhesive evenly on subfloors, ensuring proper bonding.

- Caulking Gun: Dispenses adhesive, sealant, or caulk for various flooring applications.

- Staple Gun: Used to secure underlayment, carpet padding, and other materials.

5. Leveling and Smoothing Tools:

- Floor Scraper: Removes old adhesive, flooring material, and debris to prepare the subfloor.

- Concrete Screed: Levels and smooths freshly poured concrete surfaces during flooring installation, ensuring a flat and even finish.

- Power Trowel: Used for achieving a polished finish on large concrete surfaces such as floors and driveways, saving time and effort in finishing.

- Hand Float: Used for smoothing and compacting concrete surfaces during the initial finishing stage, removing imperfections and creating a smooth surface.

6. Finishing and Trimming Tools:

- Miter Saw: Used for cutting precise angles in baseboards for a professional floor finish.

- Trim Router: Trims the edges of laminate or wood flooring for a polished look.

- Edging Tool: Achieves clean edges on carpet, vinyl, and other flooring materials.

7. Safety Gear:

- Knee Pads: Protect your knees from strain and injury during flooring installation.

- Safety Glasses: Shields your eyes from debris, dust, and potential hazards.

- Respirator: Filters out harmful fumes and dust particles, ensuring safe working conditions.

8. Maintenance and Repair Tools:

- Flooring Repair Kit: Contains putty, markers, and tools for repairing minor damage in flooring materials.

- Wood Floor Polisher: Restores the shine to hardwood floors and other finished wood surfaces.

- Grout Cleaning Kit: Removes dirt and stains from tile grout, maintaining the appearance of tiled floors.

9. Specialized Tools:

- Flooring Nibbler: Used to make curved cuts and notches in flooring materials.

- Moisture Meter: Measures moisture levels in subfloors to prevent potential issues with flooring materials.

- Undercut Saw: Trims door casings and other obstacles for a seamless fit of flooring materials.

10. Removal Tools:

- Flooring Pull Bar: Safely removes planks without damaging them or surrounding flooring.

- Flooring Scraper: Tears up old flooring materials and adhesive, preparing the subfloor for replacement.

- Tile Chisel: Designed for the removal of stubborn tiles and tile adhesive.

Conclusion

Discussed above are different types of tools used for waterproofing and flooring. We will delve into other tools used for structural work, concrete repair, concrete testing tools in an upcoming article.