Picture a tower crane idling while your crew studies a glass panel chipped at the corner. Re-ordering triggers penalties, schedule slips, and another day’s margin evaporates.

Packaging failures drain about $60 billion from U.S. companies each year—roughly $4.7 billion hits construction alone. Most boxes are built for retail, not rebar or glazing, so they buckle under forklift jolts, soak up rain, or leave parts rattling.

We can fix it. Below, we rank nine high-impact packaging options—scored for protection, ROI, sustainability, and practicality—and include a discreet link to proven custom help when you need it. Ready to shield every shipment like the project depends on it? Let’s dive in.

How we ranked the solutions

We judged every packaging option with the same yardstick so you can compare apples to apples. Protection came first; if a crate or insert cannot stop cracks and dents, cost and eco claims do not matter.

Next we weighed return on investment: upfront spend, lighter freight, and the rapid payback firms see once breakage drops.

Sustainability ranked third. Regulations are tightening, so materials that recycle easily or cycle back for reuse scored higher and keep you landfill-light.

Practicality followed. A clever design that needs a PhD to assemble never leaves the warehouse, so we favored gear crews can use with the tools and training they already have.

Versatility and speed rounded out the list. Job sites juggle odd shapes and tight timelines, so packaging that adapts to many parts and arrives quickly earned extra credit.

The scorecard below shows how each of the nine solutions stacks up across these six factors. Use it as a cheat sheet while you read the deeper dive that starts with Solution #1.

Professional custom packaging design & engineering

The big idea is simple: when packaging is engineered around your product—weight, weak points, route, and handling gear—damage drops and savings rise.

Specialist teams map every step of the trip and model shocks, vibration, and climate swings. The result is tailored crates, precise foam densities, and load paths that standard boxes cannot match. One mid-size supplier recorded an 87 percent fall in damage claims in a single quarter after adopting a bespoke design.

Sticker shock fades once the math is clear. A crate that adds two hundred dollars to freight often saves ten times that by preventing one replacement panel and the overtime that follows.

Industry voices agree. “Hire a packaging engineer at the very beginning; those decisions pay for themselves,” advises consultant Ernie Schlitt in DC Velocity.

One provider that manages the entire workflow under one roof is California-based studio Zenpack. Its custom packaging program connects strategy, design, manufacturing, and logistics so nothing gets lost between the drawing board and the job site. The team then runs new crate concepts through free-fall drop and vibration cycles in its ISTA-certified lab and uses a Kongsberg X22 cutting table to deliver full prototypes in as little as 24 hours, giving site managers a chance to vet lift points and lock specs before a production run.

Zenpack custom packaging program for construction materials

Custom work also lets you specify recyclable boards or right-size inserts, meeting sustainability goals without extra labor. Once the blueprint is set, crews pack faster because every piece has an obvious, snug spot.

Bottom line: purpose-built packaging acts as insurance that pays dividends from day one and keeps goodwill intact shipment after shipment.

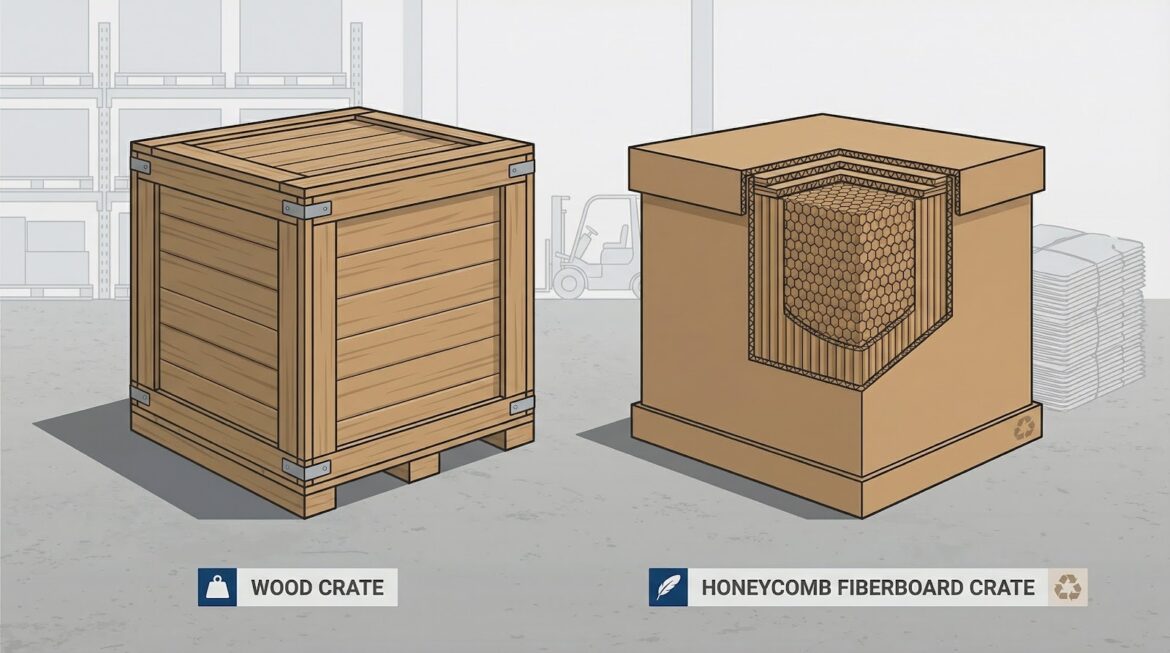

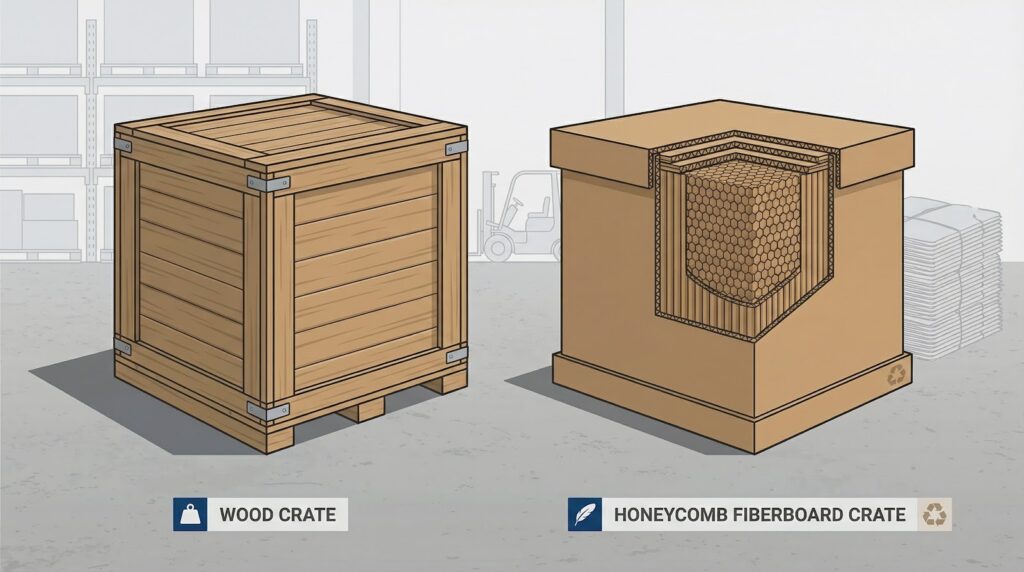

Heavy-duty corrugated crates and honeycomb fiberboard panels

Wood has long ruled the job-site crate, yet modern paper engineering now beats it at a fraction of the weight. Triple-wall corrugated boxes and honeycomb-core panels shrug off impacts that splinter pine, then move straight into the recycling stream once unpacked.

Strength is measurable. Double-wall sheets rated at 48 edge-crush test routinely survive forklift bumps and vertical loads above a thousand pounds. Add the hexagon honeycomb core and you gain a stiffness-to-weight ratio that rivals plywood while staying exempt from ISPM-15 export rules.

Lighter packaging cuts freight bills and improves safety. Crews fold a flat crate, drop in molded inserts, and load without nails or a saw. On one ceramic-tile lane we tracked, switching from wood to honeycomb trimmed 15 percent from shipment weight and ended splinter injuries during unpacking.

Sustainability follows. These fiber packs arrive with high recycled content, leave as clean OCC bales, and keep polystyrene foam out of landfills. When one material scores on protection, cost, and green metrics at once, it earns our number-two spot.

Reusable bulk packaging systems (crates, pallets & racks)

Picture a steel A-frame that carries glass panels across the country, folds flat for the ride home, then returns loaded the following week. That is reusable packaging in action.

Reusable bulk packaging racks and A-frames for glass and construction materials

A returnable rack or molded-plastic tote costs more upfront than single-use wood, yet spread over fifty trips the expense drops to pennies per shipment while landfill fees vanish. One HVAC supplier reached breakeven after nine cycles and now saves thousands of dollars each quarter on crate lumber.

Durability seals the deal. Heavy-gauge steel, high-density plastic, and aluminum rails shrug off rain and forklifts, so fragile cargo stays secure. Barcodes or RFID tags track each asset, reducing loss and tightening schedules.

The sustainability case is even stronger. Construction already sends mountains of disposable packaging to the dump. Reusables cut that waste by as much as eighty percent, a target circular-economy experts at IOM3 say the sector must meet to stay competitive.

For stable supply loops from factory to site and back, reusable systems lower cost, risk, and waste in one move.

Foam-free protective inserts (molded pulp and other bio cushions)

Expanded polystyrene once dominated interior cushioning, but landfill bans and customer pressure have shortened its runway. Molded-pulp trays and other plant-based cushions now match foam’s shock absorption while passing every recycling program in North America.

The chemistry is straightforward. Recycled paper slurry is pressed into rigid, shape-hugging shells that cradle fragile sinks, lights, and tile corners. Unlike foam, pulp does not stay compressed during long hauls, so protection remains consistent from factory dock to 40-story hoist.

Costs balance out. Tooling is an upfront bite, yet per-piece prices drop quickly at moderate volumes. When the insert heads to the blue bin instead of the dumpster, you avoid disposal fees and earn sustainability credits—a target IOM3 flags as essential for cutting construction-packaging waste.

Crews like the change too. No static-cling peanuts or flaky EPS shards blowing across the site. Just tip the pulp into the recycle skip and get back to work.

Swap a few foam blocks this quarter and watch breakage stay flat while waste and headaches fade. It is an easy upgrade that keeps regulators, clients, and the planet on your side.

Inflatable dunnage bags and smart void fill

A trailer turns, pallets slide, and brittle panels meet the floor. Most transit damage starts with simple movement, not catastrophic drops, so load-stabilising gear earns its place here.

Inflatable dunnage bags slip into gaps between crates or against container walls, then expand to lock every stack in place. Five dollars of air cushion can save five thousand dollars in scrap. Drivers brake hard, yet the freight stays still.

Inflatable dunnage bags securing construction pallets inside a trailer

Inside cartons, on-demand air pillows or paper cushions work at smaller scale. They fill empty space so parts cannot rattle, rub, or crush. Crews make only what they need, cutting material waste along with breakage.

Speed seals the deal. Bags inflate in seconds with a compressor already on the dock. No nails, no awkward strapping. DC Velocity reports that proper void fill and corner boards sharply reduced claims when freight costs spiked. The lesson stands: secure the load, secure the profit.

IoT shock and tilt sensors keep everyone honest

Data changes behaviour. The moment a bright red ShockWatch label appears on a crate, handlers lift with extra care. Add a Bluetooth tracker that logs every jolt and you gain proof, accountability, and a quick way to fix weak links.

IoT shock and tilt sensors on construction crates with tracking app

Sensors do not cushion cargo, yet they still slash incidents. When one glass fabricator placed impact indicators on every outbound rack, claims fell by double digits in a month. Carriers knew drops would be visible, so drops stopped.

Real-time units go further. A tilt alert at 2 am lets you call the driver before a fallen crate becomes broken glass. Later, you mine the data, spot patterns, and tighten standard procedures. Improvement compounds over time.

Cost stays modest. Basic indicators cost only a few dollars, reusable trackers a bit more. Compare that with one ruined HVAC skid and the return speaks for itself. As DC Velocity noted, spending pennies on monitoring helps avoid dollars lost to damage.

For fragile, high-value loads, a sensor sticker delivers inexpensive peace of mind.

On-demand box making trims cost and damage in one cut

Every inch of empty space inside a carton invites trouble. Parts slide, corners crush, and carriers bill you for shipping air. On-demand packaging machines solve all three headaches in one pass.

Feed flat corrugated sheets into a cutter, key in product dimensions, and out comes a made-to-measure box. No guesswork, no aisles stacked with the “closest” size. Crews add a few paper cushions, seal, and load.

On-demand box making machine creating right-sized cartons for construction parts

Right-sizing pays fast. Packsize told DC Velocity that demand for its machines spiked when cardboard prices and freight rates climbed, because shaving even one inch from a box cuts both material and dimensional-weight charges. One hardware distributor reduced void fill by forty percent and saw parcel damage fall nearly a third after installing a unit on the shipping line.

Speed helps too. A technician can shape dozens of custom cartons an hour, keeping pace with mixed picks headed to the job site. The software flags heavy loads and boosts board strength automatically, so protection never slips.

Upfront investment limits this tool to moderate or high-volume shippers, yet when you send varied parts daily, the math works: less corrugate, less filler, tighter packs, and fewer claims.

Compliance-ready pallets and crates prevent border and job-site setbacks

A crate that fails customs or strains a labourer’s back can cost more than a broken part. Smart shippers choose packaging that meets rules and respects handling limits before the first board is cut.

For exports, wood must carry the ISPM-15 stamp that proves pests were heat-treated out. Skip the mark and a port inspector may sideline your shipment for fumigation or even refuse entry. Many builders avoid the risk by switching to plywood panels (often exempt) or to the corrugated and honeycomb options discussed earlier.

Weight and lift points matter just as much. Keep single packages under safe manual-handling limits, or design fork pockets and sling hooks into larger skids. Clear labels such as “This side up,” centre-of-gravity arrows, and load weight help crews move with confidence instead of guesswork.

Compliance features act as low-cost insurance. They prevent avoidable delays, fines, and injuries while protecting the materials inside.

FAQ

Below is additional information many shippers ask about construction packaging. (No specific questions have been published yet.)

Conclusion

The construction sector ships fragile, oversized, and high-value components every day, yet most still rely on packaging designed for retail goods. By adopting any combination of the nine solutions above—backed by data and real-world results—builders can cut damage rates, curb waste, and protect profit margins. Whether you invest in custom-engineered crates, switch to lighter honeycomb panels, or add IoT sensors for accountability, thoughtful packaging pays for itself on the first project and every one that follows.