Wheel loaders are four-wheel-drive earthmoving machines used primarily to load loose materials with a front-mounted bucket. A left-arm assembly raises and lowers the bucket. While mobility and enlarged bucket provide wheel loader high production output and add on high cycle times. The structural build-up of wheel loaders is an added advantage. There are different types of wheel loaders for different applications and uses, which are discussed below

Types of wheel loaders

Compact wheel loaders

Modern compact wheel loaders feature high-tech components that fully comply with modern construction practices and adhere to the strictest quality requirements. The machines have built-in environmental benefits such as low emission engines and many of the parts can be recycled.

Small wheel loaders

Modern small wheel Loaders set the standard for productivity and feature the optimized Loader Linkage to handle loads with precise control, the all-around visibility from the comfort of the heated, air suspension seat inside the cab, as well as the standard fuel savings Eco Mode. The intuitive controls and compact size of this machine make it quick and easy to operate in tight spaces.

Medium Wheel Loaders

Medium Wheel Loaders are designed to handle a variety of jobs on your worksite from material handling and truck loading, to general construction, to stockpiling. With a spacious cab and low effort controls, operators will be in a comfortable and productive working environment. The reliability, durability and versatility built-in result in front loaders that are better built to meet your needs.

Large Wheel Loaders

Large Wheel Loaders are designed with durability built-in, ensuring maximum availability through multiple life cycles. With optimized performance and simplified serviceability, our machines allow you to move more material efficiently and safely at a lower cost per ton.

Technological developments in wheel loader models

Wheel loaders-More power and Smart Driving

The new wheel loader model is equipped with a 28.5 kilowatt / 38.8 engine as standard. The exhaust after-treatment is carried out by DOC and DPF. Smart Driving PRO is also optionally available for the all-wheel steer loader. This is a new feature with three different operating modes that support and relieve the operator in the respective applications whilst being fuel-efficient. In the Power Mode, the complete engine output is available. This provides an ideal basis for fast loading cycles and also for work in excavated material. In comparison to the Power Mode, the machine drives the same travel speed in Eco Mode with reduced engine speed. To reduce the noise level and to save fuel, this operator mode is above all suitable for stacking work in which the full system power is not required.

Wheel loaders-Machine design for versatile application

The quick coupler system continues as standard for efficient work when frequently changing attachments. The large lift and tear out force, in addition to precise parallel guidance throughout the total height can be achieved through the loader unit with Z-kinematics. The visual position display for bucket and fork is an immense benefit to inexperienced operators or those constantly changing in plant hire businesses or large operations. The compact wheel loaders are therefore ready for application as an all-rounder – no matter whether in use with a snowblower, mulching device, plate compactor or a cultivation device.

Wheel loaders-Modern cab design

Modern wheel loaders are coming service access with two tanks; as a result of this: the excellent distribution of weight and stability, as well as the modern cab design, have set new standards in the compact wheel loader-segment, these, in turn, ensure the additional benefit of comfort and operator-friendliness, whereby functionality and ergonomics are at the forefront. The wide entry includes additional steps, thus ensuring a comfortable and above all safe entry and exit. The optionally available, tilt-adjusting steering column is likewise helpful in this and also enables the individual steering adjustment for the operator.

Wheel loaders-Open Canopy

Ideal for rental businesses, agriculture, supply yards, warehouses, and other applications where open-cab units are preferred/acceptable, the new rugged four-post ROPS/FOPS-compliant canopy option offers excellent visibility to all sides of the machine and includes the same new upgraded electro-hydraulic controls as the enclosed-cab configuration. Modern compact wheel loaders provide operators with more reach, lift capacity, visibility and comfort compared to other light equipment.

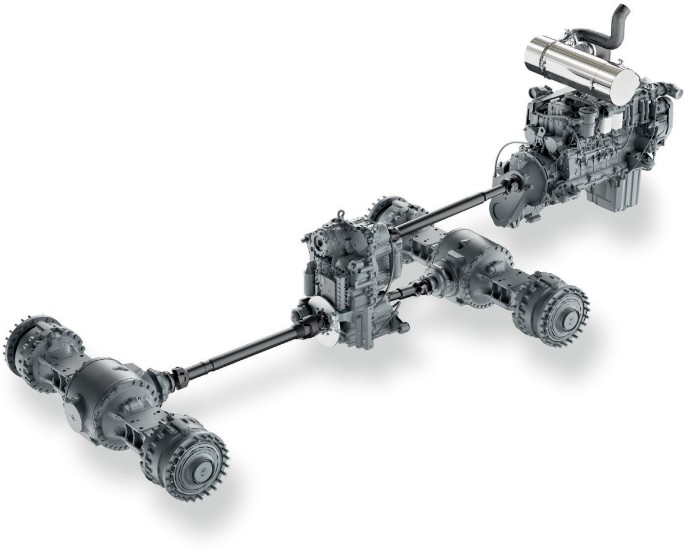

Wheel loaders-Hydraulic and drive train technology

Using innovative hydraulic and drive train technology and rock-solid quality, Modern loaders are satisfying the toughest quarry and mining production demand. The wheel loader’s Independent Work Equipment Control simplifies operation and further reduces fuel consumption, says Komatsu, by separating the accelerator pedal from the speed of the work equipment. Operating environment changes include floor-to-ceiling glass, ergonomically designed switch layouts, and a fully-adjustable five-axis console.

Conclusion

Advancements in attachment offerings over the last decade have complemented the productivity and versatility of compact wheel loaders. Today, they are commonplace in construction sites and landscaping projects, given their optimum size, new attachment options, and low-fuel consumption. Compact track loaders offer the benefits of better maneuverability, lifting abilities, and multiple attachments compatibility. As such, manufacturers are profoundly investing in them. Although they are cost-intensive, they are the best bet, especially in the regular application in rough conditions.

Image Source: volvoce.com, rocktoroad.com, cat.com, deere.com, oemoffhighway.com, pintrest.com, wackerneuson.be, komatsuindia.in, springernature.com