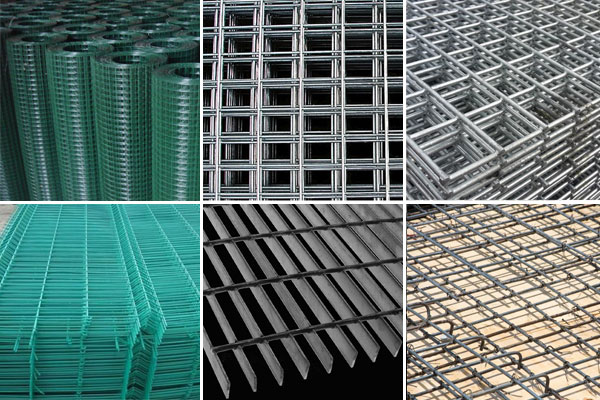

Welded wire mesh is made of intertwined wires which are welded together at regular intervals with equal gaping, thereby forming a barrier. Welded wire mesh is used in arrays of small to large projects. It strengthens the integrity of concrete structures. The welded wire mesh acts as a durable core for the concrete. The concrete will eventually become brittle and crumble but the wire mesh greatly extends the performance life of the concrete. They are ideal for temporary or permanent partitions. Depending upon the application, welded wire meshes are created in different types and styles. Based upon the welding process and the different types of materials used in its construction, these wires may be divided into categories. They can also be customized as per need and requirement.

Different types of welded wire mesh

PVC Welded Wire Mesh

This type of mesh is coated with fine PVC powder for corrosion resistance. The plastic coating protects the underlying metal as well as imparts color to the finished products. These kinds of mesh provide good corrosion resistance and qualities that are not usually found in average wire meshes. Wire mesh panels made of PVC welded have characteristics of their fine qualities, sturdiness and durability. PVC coated and sprayed welded wire mesh comes with corrosion resistance, aging resistance, sunshine resistance and weather resistance. It can be used in farming, construction, transportation and mining for the protection of structures, safety segregation, keeping of poultry and livestock, and decorations, etc.

Galvanized Welded Wire Mesh

Galvanizing can occur either before or after wire mesh is manufactured – both in woven form or welded form. After the welding or weaving is completed, the mesh is dipped into a bath of molten zinc. The zinc bonds to the wire’s surface, thoroughly sealing it and protecting it from rust and corrosion. It can be done through Electrogalvanizing in which uses electricity to bond zinc to the underlying metal wire or hot-dipping in which the product is dipped in a galvanization tank full of molten zinc at a temperature of around 450°C. One of the main benefits of a galvanized wire mesh is that it tends to offer a wide variety of opening sizes and diameter wires. It is used on wire meshes for a variety of applications of the finished product. From beautification of the fence to heavy industrial area

Welded Stainless Steel Wire Mesh

This type of mesh is created by welding stainless steel together at the intersections to form a uniform steel barrier. It provides strength and longevity to its users. Stainless steel welded wire mesh is uniform in appearance. It is one of the most popular forms of wire mesh out there. Its wires are joined by resistance welding, rather than a filler metal, creating a strong, consistent product. It can be cut down to smaller sizes, like rectangles, squares or discs. The stainless steel wire mesh filters are widely used because it never reacts with fluids and hence this enhances its longevity and performance. It is widely used in transportation, agricultural, mining, horticulture, entertainment and other service sectors.

Welded Wire Fencing

This type of meshed wire is available in rolls or panels which is used for fencing. They are pre-constructed before application. It is available with or without galvanization. The non-galvanized version comes for a lower cost. They’re easy to install, especially when remodeling a deck on your building. Rolls are custom-made to your specifications, need minimal to no cutting and can typically be installed by one to two people who are skilled. Wire fence rolls are perfect for jobs that have larger linear footage to cover which may require work crews and professional installers. There are also additional materials like posts, rings, pliers and everything else you need to install a fence. Panels are pre-constructed in set shapes and sizes to fit the structure it is being used. It can be dismantled and reused easily.

Welded wire fencing cannot be cut by traditional standards, as it is a thick gauge steel fence that requires torches and labor to penetrate. Welded wire fencing is one of the most stable fence structures on the market, as it is constructed from steel, and the actual posts that hold it up are mounted into the ground equally as deep with cement footings. It is used in residential commercial, agricultural and industrial areas.

Welded Steel Bar Gratings

Welded steel grating is produced through automatically resistance welded steel. The bearing bars and crossbars are resistance welded under high heat and pressure to form a permanent joint. This technology can not only ensure the rugged structure of welded steel grating but also can retain a smooth and flat surface, which is easy and free to walk. Welded steel grating can be made of various materials, such as carbon steel bars, aluminum steel bars and stainless steel bars. Welded steel bar grating is resistance welded to create a rugged, one-piece constructed panel. The bearing bars are automatically resistance welded at the contact point with the crossbars and under a combination of high heat and pressure, are fused to form a permanent joint. Welded Steel Bar Grating is the most popular of all grating types due to its strength, cost-efficient production and ease of installation. It is used in most general industrial plants as well as commercial buildings, it has wide applications as walkways, platforms, safety barriers, drainage covers and ventilation grates. Welded steel grating has an anti-slip surface, corrosion resistance, good drainage function, high strength and load capacity.

Welded Wire Fabric for Slab Reinforcement

The fabric when reinforced to the slab increases tensile strength compared to steel which is extremely strong in tension. Welded Wire Fabric (WWF) is a prefabricated reinforcement consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. The welding of the wires is achieved by electric resistance welding with solid-state electronic control and all the spacing is controlled by an automatic mechanism of high reliability. The wires used in the fabric are cold drawn from controlled quality mild steel wire rods with carbon content generally less than 0.15%. The cold drawing through a series of tungsten carbide dies results in high tensile strength and increased yield strength material of accurate dimensions. The mechanical interconnections established via welds to cross-wires are responsible for stress transfer from concrete to steel and vice-versa in the case of welded wire fabric. It can be used in slabs and ferrocement works.

Image Source: fenceandconcertina.com, gads.in, leehills.ie, indiafence.com, mcnichols.com, depositphotos.com