Sealants are construction chemicals used to create a barrier or seal gaps, joints, or seams between surfaces. They are applied to prevent the passage of air, water, dust, or other substances through the sealed area. Sealants are also applied to joints in construction, such as expansion joints or concrete joints, to provide flexibility and prevent moisture, air, or contaminants from entering or escaping.Depending on the specific application and requirements, sealants may be formulated to have different properties such as adhesion strength, elongation, curing time, resistance to chemicals or UV radiation, and durability.

Advantages of sealants

Sealants offer several advantages in various applications. Here are some of the key advantages of using sealants:

1. Water and Weather Resistance: Sealants create a watertight barrier, preventing the passage of water through joints, gaps, or seams. They offer excellent resistance to moisture, rain, and humidity, making them ideal for outdoor applications or areas prone to water exposure. Sealants also provide protection against weather elements such as wind, UV radiation, and temperature fluctuations.

2. Flexibility and Movement Accommodation: Sealants are designed to be flexible, allowing them to accommodate movement or expansion between joined surfaces. This flexibility ensures that the seal remains intact even when there are changes in temperature, vibrations, or structural movements. It helps prevent cracking or separation of the sealant, maintaining the effectiveness of the seal over time.

3. Adhesion and Bonding: Sealants exhibit strong adhesion to a wide range of substrates, including metals, concrete, glass, wood, plastics, and ceramics. They create a secure bond between surfaces, providing excellent sealing properties. Sealants help fill gaps or irregularities in the substrate, enhancing the strength and integrity of the joint.

4. Durability and Longevity: Sealants are formulated to withstand harsh conditions and maintain their sealing properties for an extended period. They are resistant to environmental factors such as UV radiation, chemicals, and aging. Sealants offer long-term performance and durability, reducing the need for frequent maintenance or resealing.

5. Versatility and Wide Range of Applications: Sealants have versatile applications across different industries and sectors. They are used in construction for sealing windows, doors, roofing, expansion joints, and concrete joints

6. Aesthetics and Finish: Sealants come in various colors and formulations, allowing them to blend seamlessly with the substrate and provide an aesthetically pleasing finish. Some sealants are paintable, enabling customization to match the surrounding surfaces.

Different types of sealants

There are various types of sealants available, each designed for specific applications and materials. Here are some common types of sealants used in the construction industry:

1. Silicone Sealants: Silicone sealants are widely used due to their excellent flexibility, durability, and resistance to weathering and temperature extremes. They provide a watertight seal and have good adhesion to a wide range of materials, including glass, metal, ceramics, and certain plastics. Silicone sealants are commonly used for sealing joints in windows, doors, facades, and other exterior applications.

2. Polyurethane Sealants: Polyurethane sealants offer good adhesion and elasticity. They provide strong and durable seals, making them suitable for both interior and exterior applications. Polyurethane sealants have excellent resistance to moisture, chemicals, and UV radiation. They are commonly used for sealing expansion joints, concrete joints, roofing, and automotive applications.

3. Acrylic Sealants: Acrylic sealants are economical and easy to apply. They have good adhesion to a variety of porous and non-porous surfaces such as wood, concrete, and plasterboard. Acrylic sealants are typically used for interior applications, including sealing gaps in drywall, baseboards, and trim.

4. Butyl Rubber Sealants: Butyl rubber sealants are known for their excellent water resistance and airtight properties. They have good adhesion to various surfaces, including metal, concrete, and glass. Butyl rubber sealants are commonly used for sealing joints in roofing, gutters, and metal panel systems.

5. Polysulfide Sealants: Polysulfide sealants offer excellent resistance to fuels, oils, and chemicals. They have good adhesion to a wide range of materials, including metals, glass, and masonry. Polysulfide sealants are commonly used in applications where resistance to petroleum-based products or chemical exposure is required, such as sealing joints in fuel tanks, swimming pools, and chemical processing facilities.

6. Hybrid Sealants: Hybrid sealants combine the properties of different types of sealants to provide enhanced performance. They may incorporate elements of silicone, polyurethane, or other chemistries. Hybrid sealants offer good adhesion, flexibility, and weather resistance, making them suitable for various applications, including construction joints, window installation, and facade sealing.

7. Specialty Sealants: There are also specialized sealants available for specific applications. Examples include fire-rated sealants, soundproofing sealants, concrete joint sealants, and underwater sealants. These sealants are formulated to meet specific performance requirements dictated by the application.

Sealant Applications

Sealants play a crucial role in the construction industry and are used for various applications to create effective seals and prevent leakage or intrusion of air, water, or other substances. Some common applications of sealants in construction include:

1. Window and Door Sealing: Sealants are used to seal the gaps and joints around windows and doors. They create a waterproof barrier, preventing air drafts, water infiltration, and noise penetration.

2. Expansion Joints: Expansion joints are designed to accommodate the movement or expansion of building materials due to temperature changes, settling, or structural shifts. Sealants are applied in expansion joints to create flexible and durable seals, allowing the joints to expand or contract while maintaining a watertight and airtight barrier.

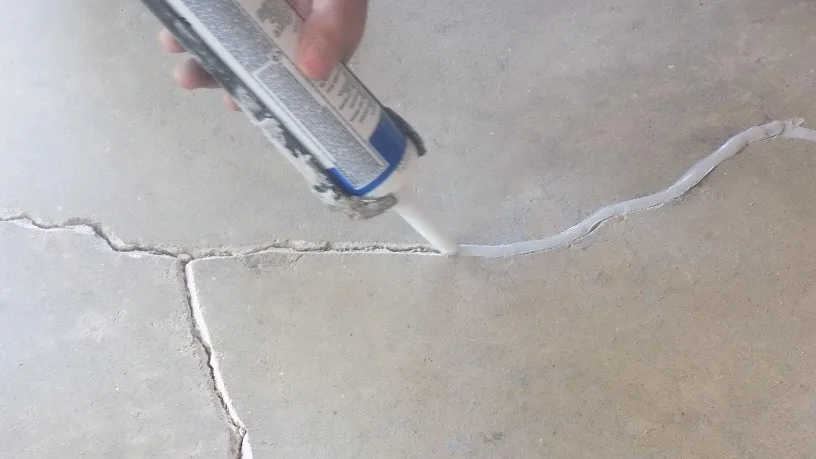

3. Concrete Joints and Cracks: Sealants are used to seal joints and cracks in concrete structures, such as floors, walls, bridges, and highways. They prevent the intrusion of water, chemicals, and debris, which can cause damage and deterioration of the concrete.

4. Roofing: Sealants are applied in roofing applications to create waterproof seals and prevent leaks. They are used for sealing roof penetrations, such as vents, skylights, and chimneys, as well as for sealing joints, seams, and flashing details.

5. Bathroom and Kitchen Sealing: Sealants are used in bathrooms and kitchens to create watertight seals around fixtures, such as sinks, bathtubs, showers, and countertops. They prevent water seepage, mold growth, and damage to surrounding materials.

6. Facades and Curtain Walls: Sealants are applied in facade and curtain wall systems to seal the joints between different components, such as panels, frames, and glass. They provide weather resistance, thermal insulation, and structural integrity to the building envelope.

7. Concrete and Masonry Restoration: Sealants are used in the repair and restoration of concrete and masonry structures. They are applied to fill cracks, gaps, or voids, providing structural reinforcement and preventing further deterioration.

How can sealants be applied?

Sealants can be applied using various methods depending on the type of sealant, the application requirements, and the size and complexity of the sealing project. Here are some common application methods for sealants:

1. Caulking Gun: The most common method of applying sealants is with the use of a caulking gun. The sealant is packaged in cartridges or tubes that fit into the caulking gun. By squeezing the trigger of the caulking gun, the sealant is forced out through the nozzle in a controlled manner. This method allows for precise application and is suitable for sealing joints, gaps, and seams.

2. Brush or Roller: Some types of sealants, particularly those with a more liquid consistency, can be applied using a brush or roller. This method is commonly used for applying sealants to larger areas, such as roof coatings or waterproofing membranes. The brush or roller helps spread the sealant evenly and ensures proper coverage.

3. Spray Application: Spray application is used for certain types of sealants, such as aerosol sealants or sprayable coatings. This method is often employed for larger surface areas or when a thin, uniform coating of sealant is required. Spray equipment, such as airless sprayers or spray guns, is used to atomize the sealant and apply it in a fine mist.

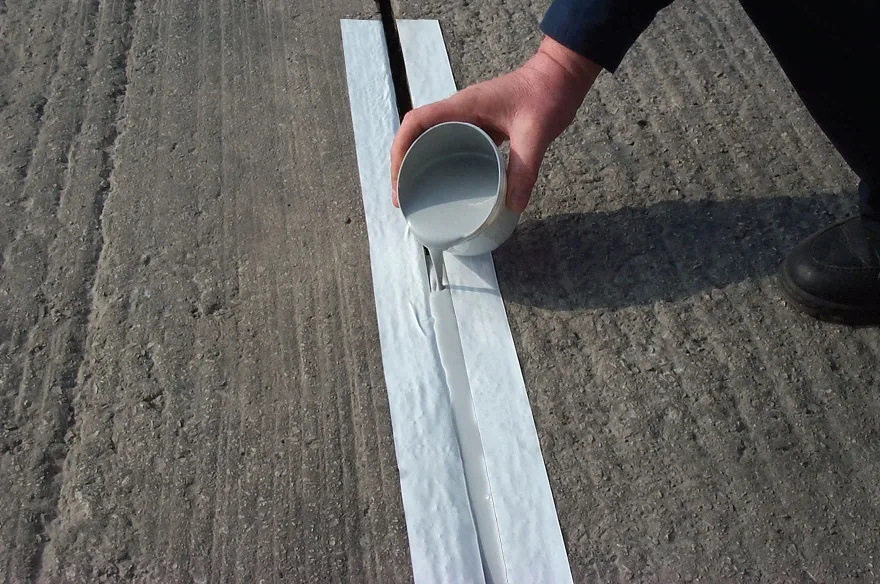

4. Pouring or Troweling: Thicker sealants, such as epoxy or polyurethane-based sealants, may be applied by pouring or troweling. This method is suitable for applications where a thick layer or a specific shape is required. The sealant is poured onto the surface and spread using a trowel or a similar tool.

5. Injection: Sealant injection refers to a method of applying sealants by injecting them into specific areas or cavities. A specialized injection gun or pump is used to inject the sealant directly into the desired area.Once the sealant is injected, it undergoes a curing process to harden and create a durable seal. This method is often employed for concrete crack repair, where the sealant is injected into cracks to fill and seal them.

It’s important to follow the manufacturer’s instructions and guidelines for the specific sealant being used. Proper surface preparation, including cleaning and priming if required, should be done before applying the sealant. It is important to ensure proper adhesion, complete coverage, and sufficient curing time for the sealant to achieve its intended performance.

Conclusion

Sealants have become indispensable in the construction industry for their ability to provide watertight seals, improve energy efficiency, and ensure structural integrity. Their versatility and effectiveness make them essential construction materials used for creating durable and high-performance buildings.