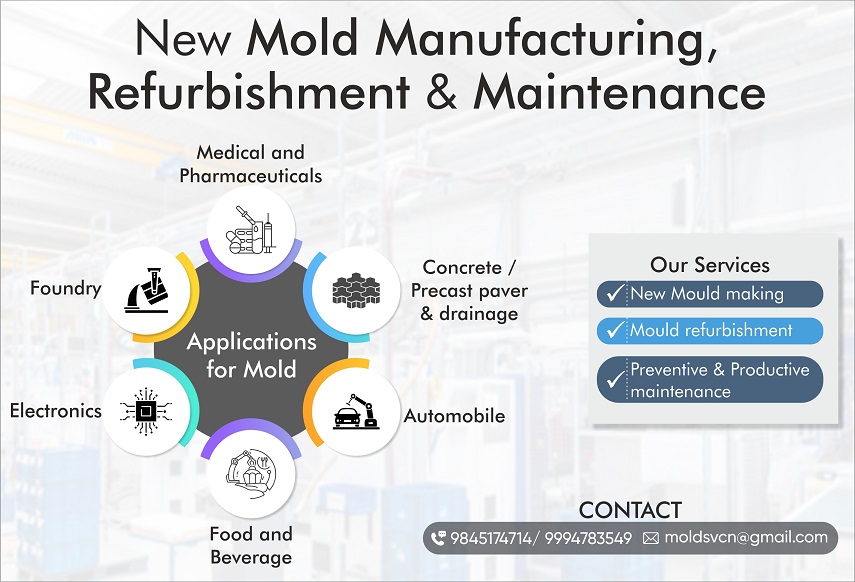

Mold manufacturing repair and refurbishment are essential processes to maintain and extend the lifespan of machinery and tools. Over time, molds can experience wear, damage and performance issues due to factors like repeated use, harsh operating conditions, or improper maintenance. Mold maintenance can help prevent these. Mold maintenance involves regular inspections, cleaning, lubrication, repairs, and adjustments to ensure the mold’s functionality, accuracy, and longevity. SVCN provides mold manufacturing, refurbishment and maintenance services to get the mold back in working order by using a multitude of machines and tools.

Our services

Mold manufacturing

We undertake mold manufacturing for concrete and precast which involves creating customized molds. These molds or forms are used to produce concrete components with specific shapes, sizes, and surface finishes. Concrete mold manufacturing is crucial in various construction and architectural applications. We manufacture customized Concrete paver mold, Concrete panel mold, Precast concrete mold and Precast drainage mold.

Mold refurbishment

We measure the mold’s alignment features, comparing them to their baseline “new” condition, and refurbishing them as necessary. We repair and replace worn-out components. Proper alignment and fit of mold components are crucial for maintaining part quality and ensuring smooth operation. Technicians verify that all components are correctly aligned and fit together precisely to avoid issues like flash, dimensional inaccuracies, or excessive wear. Our services include;

- Parting line repair

- Alignment

- Cavity/core repairs

- Venting repairs

- Hot runner repairs

- Ejector system repairs

- Complete mold refurbishment

Preventive Maintenance

In addition to regular maintenance, we take preventive measures to identify potential problems before they escalate. Our services include checking mold function, identifying signs of wear or damage, and implementing corrective actions to prevent issues from worsening.

We can do an on-site evaluation of your mold refurbishment needs before they reach a critical stage which will provide you with the planning tools necessary to expedite the work and reduce the possibility of lost production due to unforeseen mold service problems. Upon receiving the mold at our facility, we will present you with a detailed analysis of the mold based on a complete teardown and inspection.

For more details contact;

Email – moldsvcn@gmail.com, Phone – 9845174714 / 9994783549