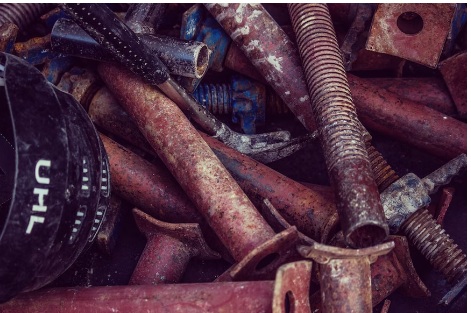

Rust inhibitor primers are a game-changer in terms of protecting metal surfaces from corrosion and ensuring their longevity across numerous industries. Offering an effective barrier against the onset of rust, these versatile coatings have become indispensable in fields such as automotive manufacturing, marine applications, construction projects, and industrial equipment production.

Dive into the world of rust inhibitor primers to discover how they work, their common uses, and why these essential treatments can make a lasting difference in preserving metal assets.

What Are Rust Inhibitor Primers?

Rust inhibitor primers, in essence, are coatings applied to metallic surfaces to provide protection against rust. Much like other corrosion protection methods, these primers form a barrier, preventing moisture and oxygen from coming into contact with metal surfaces.

Industries such as automotive, marine, construction, and industrial equipment manufacturers make use of these primers to prolong the life of their products and reduce corrosion-related issues.

How Do They Work?

Rust inhibitor primers consist of special chemical substances such as zinc or epoxy, which form an adhesive, durable layer that helps impede the rusting process. Their application helps in safeguarding metals from degradation.

5 Common Uses of Rust Inhibitor Primers – and When They Are Essential

1. Automotive Industry

Rust inhibitor primers are a must in the automotive industry as they help protect car parts from corrosion, thus increasing longevity. They’re essential during the manufacturing process when metal parts are exposed to moist environments, and prone to causing rust. A rust inhibiting primer will safeguard key components, ensuring long-term durability and enhanced performance.

2. Marine Applications

Boats and ships operate in harsh, saline environments where metal surfaces require extensive protection from oxidation. Using a rust inhibitor primer on these surfaces is paramount to prevent deterioration due to saltwater exposure. It’s an essential step during both the manufacturing and maintenance processes for any watercraft, securing their structural integrity.

3. Buildings, Bridges, and Infrastructure

In construction projects involving metal structures – such as bridges or buildings with metal exterior cladding – rust prevention primers become crucial for preventing premature wear or failure of crucial components. They’re especially important in areas with high humidity or proximity to saltwater bodies like coastal regions since their corrosive nature makes protecting infrastructure a priority.

4. Outdoor Furniture and Equipment

Garden furniture, playground installations, or outdoor sports equipment often use metallic frames. These can rust easily when left exposed to the elements without proper protection provided by a primer specifically designed for such purposes. Applying rust inhibitor primers can help extend their lifespan by keeping corrosion at bay while preserving both functionality and visual appeal.

5. Industrial Equipment Manufacturing

Industries that rely on machinery and equipment made of metal components also benefit greatly from using rust-inhibiting primers during production because these devices are often subject to heavy wear or exposure to aggressive chemicals in factories or other workplaces that can evoke the corrosive process faster than normal.

In summary, rust inhibitor primers are a crucial component to have in your arsenal when working with metal in various projects and industries. They play a vital role in shielding various metallic surfaces against corrosion, which could otherwise compromise their strength and performance over time. They also help keep the metal surfaces where they are applied aesthetically pleasing throughout their lifespan.

Bottom-line

It’s important to use a rust inhibitor primer whenever working with metal surfaces that are vulnerable to corrosion, especially in moist or saline environments. Key examples include automotive components, marine applications, infrastructure projects, outdoor furniture and equipment, and industrial machinery manufacturing.

By carefully applying these primers during manufacturing, construction, or maintenance processes, you can significantly prolong the life of metal assets while maintaining their structural integrity and visual appeal.