Self-drilling screws have a fluted tip, almost like a drill bit, to dig into the material before its threads drive through it. They also come with a variety of options for the head, tip and other characteristics. The self-drilling screws are what you need to penetrate thicker metal such as 22 gauge.

Self-drilling screws are used for many metal applications but weren’t intended to go from metal to wood. Most of the time, it is this type of screw that makes the deck-to-building connection in a deck-construction project. These types of screws have tips numbered one through five, which refers to the thickness of the metal it can penetrate without a pilot hole.

Screws are the weakest link between the metal sheets and the structure. Compromise in quality leads to failure and costly repairs.

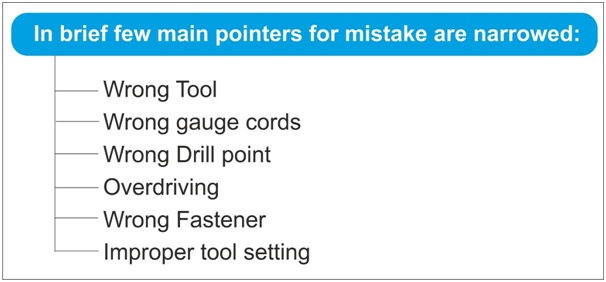

The instances for the wrong installation:

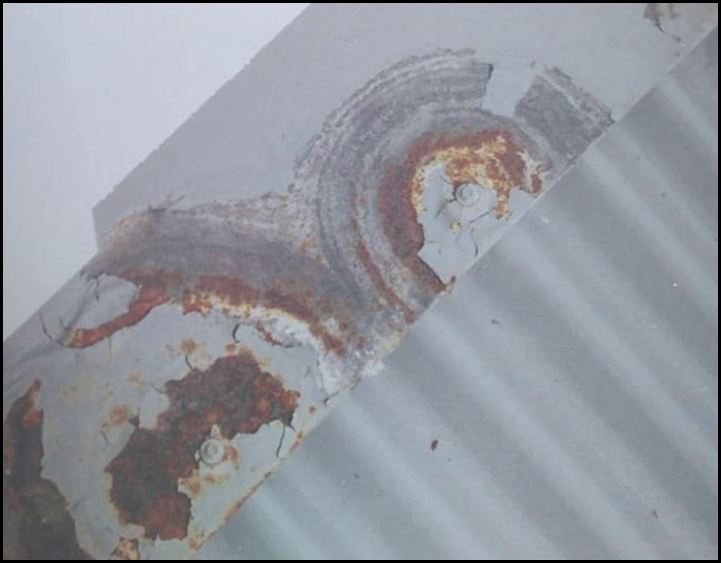

1 – Screws wrongly fixed in the valley. Failure/Corrosion on sheets due to poor quality.

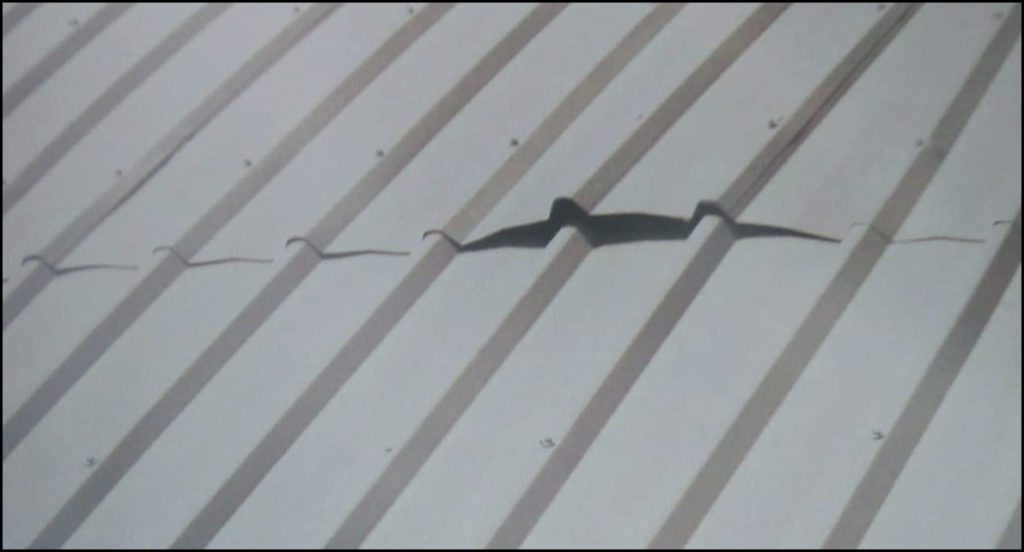

2 – New metal sheets installed with self-drilling fasteners, sometimes may be given way due to screw stress, installation becomes a challenge.

3 – Washers that are conductive leads to corrosion. Corrosion leads to stains on the building.

4 – Stains and corrosion might occur on cladding due to poor quality fasteners.

5 – Number of fasteners need to adequate or else sheets might flow away

6 – Reputation is rusted over a stained roof.

7 – Corrosion on the roof might occur due to fasteners.

8 – Screws, when not installed correctly, might loosen up which might occur due to lack of holding the purlins

The overview of issues faced;

Creating Awareness

There is a lack of awareness for self-drilling screws in general which results in economical; and structural loses. Given instances above are the prime causes for such mishaps. There is a general need for guidelines and standards that needs to be followed. Coating and size awareness are a few of the primary matters that need to be checked and standardized.

Australian & International Standard AS3566 Class (March 2002) is perhaps the best guideline we have at present.

Tender Specifications of Self Drilling Screws

Self Drilling Screws Drill their own hole and taps the thread and hold the metal roof to the Secondary membrane. The Screws provide high pullout strength, shear strength & maximum thread engagement and positive fastening in structural steel.

Self Drilling Screws Meeting the Australian & International Standard AS3566 Class (March 2002) which details as follows:

- Salt Spray Test Certificates (ASTM B117) for 800 Hrs.

- 15 Cycles of Kesternich Test in accordance to DIN 50018. (Condensing the atmosphere containing Sulphur dioxide at level SFW 2.05.)

- Relative Humidity in accordance with ASTM D2247 for 1000 Hours.

- Test Cycle of 4 Hours of UltraViolet Radiation as per ASTM G154 for 2000 Hrs.

Language Self Drilling Screws Hexagon Flange Head With a Drilling Capacity of 12mm Thick Hot Rolled Steel with Fine Thread Low Carbon EPDM Seal with a Blue Mark with RustShield Coating 3 (Electro PolySeal V E-coating) Coated Screws and a Separate METAL Bonded EPDM Washers:

The steel sheet shall be valley fastened with nominal 20 μm zinc coated or nominal 25 μm zinc- E-Coating, Hexagon Flange head, self-drilling screw as per AS 3566-2002 Class 3 fasteners of approved make (ROOFIX or equivalent) with Blue Strip EPDM washer as per the requirement considering the profile shape and design load. The fastener size shall be calculated as per the design or manufacturers recommendations. The profile sheet, fastener size etc. shall be approved by the concerned authority the measurement shall be based on finished/covered surface area. Fixing of sheets with imported 12g. -24 tpi self tapping self drilling screw, EPDM washers, applying poly sulphide sealant on all screws and rivets to make the screw holes water- proof and corrosion proof etc.

Closing Note

The guidelines are very important for screwing issues. Neglecting these might cause disastrous effect. In the most basic sense, the benefits of rules and regulations in business are that they protect the company. Following rules and regulations help experts understand what is expected of them and what will happen if they violate the rules. It makes for a stable office environment where people feel safe to come to work, to be themselves and to go about their business. Choosing experts who abide by rules is the key here.

Author: Hitesh Parmar, MD, REALM INTERMEDIATES PVT LTD.

Website: – www.realmindia.com