Roofing sheets are used as envelopes in building structures. These are durable and can be easily installed. These are resistant to rust and require very little maintenance. You must select the one that is appropriate for your circumstances. Not every roofing sheet is made equal, and some are better suited to certain projects than others. Your roof is as strong as your material choice. The roofing sheets market has undergone change owing to more industrial applications and a move towards newer material rather than conventional ones.

Given below are popular roofing sheet types and their application areas.

Different Types of Roofing Sheets

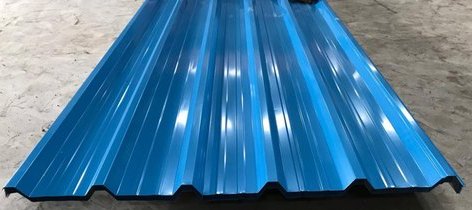

Corrugated roofing sheets

Corrugated roofing is highly durable and it is because of its shape. These sheets require the support strips to stabilize the material since the screws for fastening do go through the peak of the ribs. The curvature of the ribs and valleys prevents the screws from sealing adequately in the valleys. Because of the special corrugated shape, flimsy and lightweight metals like aluminum can also be equipped to undergo decades of weather beating. The most popular corrugated sheet is a galvanized steel sheet, which is used mostly as the base material.

Application – These roofing sheets are ideally used for protecting garages, porches and sheds.

Polycarbonate roofing sheets

Polycarbonate roofing sheets are available in a variety of qualities and thicknesses. They are much lighter in weight, yet durable, and resistant to breakage and cracks. They can be easily handled and can be fixed with the help of screws and support rods, or can be easily welded. Also, these sheets can be easily cut with the help of sharp-edged scissors and circular saws without the need for any additional tools and machinery. Polycarbonate roofing sheets being so strong and flexible helps the structures it is used to be more creatively designed. One of the most beneficial features of polycarbonate is that it lets in maximum sunlight while keeping out the harmful UV radiation. Therefore, it is the ideal choice when you want maximum light to come in without being harmful.

Application – Polycarbonate roofing sheets are widely used in industrial and large-scale commercial buildings.

Corrugated polycarbonate roofing sheets

Corrugated polycarbonate roofing sheets are available in a range of choices for light transmission and possess fire-resistant properties. These roofing sheets are manufactured with precise specifications to find an apt use in industrial roof illumination and daylight cladding. The use of corrugated polycarbonate roofing sheets is greatly beneficial in enhancing daylight harvesting. With growing concern over the environment, these types of sheets are perfectly fitting.

Application – These sheets are used for commercial establishments, industrial applications, and warehouses.

Metal roofing sheets

Metal roofing sheets is a popular option as they come with great insulating properties. They are made of Zinc, Aluminium, Copper and Tin. Metal roofing provides many advantages, including the ability to withstand nearly any type of weather condition. Metal roofing comes in many different colors and finishes including the look of natural cedar shakes or stone. It has greater fire resistance and the ability to withstand a storm without damage.

Application – These sheets can be applied in garden buildings, garages, household cladding and industrial roofs.

Cladding metal roofing sheet

Cladding metal sheet roofing acts as a covering building material with a ‘protective layer’ to provide several practical and aesthetic advantages. They are composed of aluminum or steel. These types of roofing sheets shield the internal building materials from the harsh elements and increase the mechanical stability of the structure. The cladding protects from changes in temperature, wind, water absorption, sunlight and pollution, all of which can damage the structural integrity of a building and its aesthetics.

Application – These types of sheets are used in storage buildings.

Plastic roofing sheets

Plastic roofing sheets are light in weight, making them easy to carry, transport, and install. They are durable and cost-effective as compared to metal sheets. These sheets are easy to clean and are resistant to chemicals and corrosion.

Application – They are mainly used as garden sheds or for covering temporary structures.

Installing roofing sheets

Conclusion

With evolving times there has been significant development in the use of various materials for roofing sheets. Pre-painted ZINCALUME steel, Galvalume Steel, and Zinc Aluminium alloy coated Steel have foreseen great demand. The usage of RCC roofs, GI roofing sheets, Unplasticized Polyvinyl Chloride Roofing Sheets, and asbestos-cement sheets has also increased predominantly. There are so many options nowadays that sometimes it can be overwhelming. Take expert help on deciding what type would be befitting for your project needs.

Image Source: supremewolf.com, windventilators.net, tuflite.com, shribalajiroofing.in, bushburycladding.co.uk, pintrest, yarkermetalroof.com.my