It has become a necessity to expand and upgrade national highways due to the increased traffic and the extension of the logistics networks. Basically, most of the current stretches of highways were planned a long time ago when these were two-lane roads, and now they carry a heavier traffic of passenger and freight vehicles. Road widening projects are instrumental in the solving of traffic capacity problems, in the reduction of the travel time, in the making of a road safer, and in the preparation of the corridors for the future.

Just one addition of lanes is not the only point of road widening. Along with that, the work involves changing the horizontal and vertical geometry, strengthening the pavement layers, upgrading the drainage, modifying the structures, and integrating the safety systems.The step demands joint planning, engineering evaluation, and the employment of mechanized construction systems.

Challenges in Highway Widening

Widening projects encounter several problems that affect the design and the planning of the construction.

1. Limited Right-of-Way (ROW)

There are highways passing through the city areas, farmlands, or even the environmentally sensitive zones. ROW restrictions limit the possibility of symmetrical widening and, therefore, usually imply selective widening or realignment.

2. Traffic Handling

The widening should be done with the continuation of the traffic flow. The safety of the work zone, the limited space for the work, and the high number of vehicles make it more difficult to carry on operations.

3. Pavement Condition Variability

Often, the existing pavements have uneven structural capacity. They must first be strengthened, and then new layers can be put on top.

4. Utility Congestion

There is a need for the relocation of water pipeline, electrical poles, and telecom cables and drainage network before the construction can take place.

5. Structural Modifications

The change of the support, the widening, or the entire rebuilding of the bridges, culverts, and underpasses, which are at the side of the carriageway, is necessary.

6. Environmental Compliance

Cutting trees, controlling dust, managing noise, and disposing of the excavated materials require following the environmental standards.

Stages of Road Widening and Upgrading

Widening is carried out through sequential phases, following MoRTH, IRC, and project-specific guidelines.

- Survey, Investigation and DPR Preparation

- Detailed preliminary studies determine the widening strategy.

a. Traffic Survey

- Classified volume count

- Origin–destination survey

- Axle-load data to predict pavement strengthening needs

b. Pavement Condition Survey

- Roughness index

- Deflection tests (BBD/FWD)

- Rut depth and crack assessment

c. Topographical Survey

Digital surveying tools such as Total Stations, drones, and LiDAR are used to map alignment, structures, and obstructions.

d. Geotechnical Investigation

- Boreholes

- Soil testing

- CBR value estimation

- Foundation stability checks for structures

e. Inventory Mapping

- Record of existing culverts, bridges, retaining walls, safety furniture, and utilities.

- The survey phase decides whether the widening will be symmetric, asymmetric, or require realignment.

Land Acquisition and Utility Shifting

Where ROW is inadequate, land is acquired under relevant regulations. Utility shifting is coordinated with departments handling:

- Electricity

- Water supply

- Gas lines

- Telecom

- Irrigation channels

Proper planning helps avoid delays during construction.

- Traffic Diversion and Work-Zone Management

- Widening in live traffic conditions demands careful management.

Methods Used

- Temporary diversions and bypass roads

- One-way controlled movement

- Barriers and reflective signage

- Night-time construction in urban stretches

- Safety marshals and flagmen

Earthwork and Foundation Preparation

Earthwork forms the base of road widening.

a. Excavation

Excavators and dozers remove soil on the widening side. In rolling terrain, cutting slopes are stabilized with turfing or geosynthetics.

b. Embankment Formation

Where widening requires filling, embankments are built using approved soil. Each layer is compacted to achieve densities specified in MoRTH standards.

c. Subgrade Preparation

- Minimum required CBR

- Layer-by-layer compaction

- Use of soil improvers or geotextiles when needed

Soft patches are removed and replaced before structural layers are added.

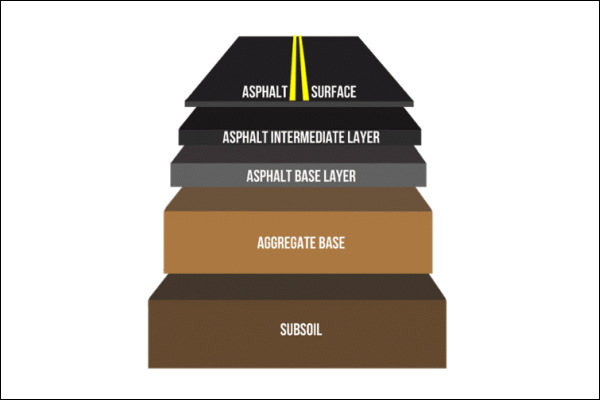

Pavement Layer Construction

Widening of pavement involves granular and bituminous layers.

a. Granular Sub-Base (GSB)

Placed layers using pavers and compacted with rollers. Grading selection follows MoRTH specifications.

b. Wet Mix Macadam (WMM)

Mixed using WMM plants and laid with uniform moisture control. Compaction ensures required stability.

c. Bituminous Layers

Based on traffic load, typical layers include:

- Dense Bituminous Macadam (DBM)

- Stone Matrix Asphalt (SMA) in heavy-load corridors

- Bituminous Concrete (BC)

Modified binders (PMB/CRMB) are used to enhance durability.

d. Milling the Existing Surface

Old bituminous layers are milled to ensure bonding with new layers and maintain profile.

Geometric Improvements

Upgrades ensure the highway meets design speed and safety norms.

- Improving horizontal curves

- Adding superelevation

- Removing steep gradients

- Increasing sight distance

- Realignment of sharp bends

- Removal of roadside obstructions

Drainage Enhancement

Drainage is one of the necessary elements of pavement longevity.

a. Longitudinal Drains – They are built along the shoulders in order to stop the water from accumulating.

b. Cross-Drainage Works – Installation or replacement of pipe culverts, slab culverts, and box culverts is done.

c. Sub-surface Drains – Their usage is limited to stretches of road that have a high water table and poor natural drainage.

d. Median Drains – They are typical in six-lane and eight-lane corridors.

Good drainage lessens the chances of pavement damage and saves maintenance cost.

Equipments Used in Widening Projects

Highway widening relies on mechanized construction for efficiency.

Earthwork Equipment

- Hydraulic excavators

- Dozers

- Backhoe loaders

- Motor graders

Compaction Equipment

- Vibratory rollers

- Pneumatic tyred rollers

- Mini-compactors in constrained zones

Pavement Equipment

- Hot mix plants

- WMM plants

- Sensor-based bitumen pavers

- Tandem rollers

- Milling machines

Conclusion

Widening and upgrading of national highways is an integrated engineering activity involving surveys, land acquisition, traffic management, earthwork, pavement construction, structural extension, and safety system installation. The process requires alignment with IRC and MoRTH standards and careful coordination between stakeholders. Modern construction technologies, mechanized equipment, and improved materials help deliver faster and more reliable outcomes. As India expands its logistics and economic corridors, highway widening projects will continue to play a key role in strengthening connectivity and supporting national development.