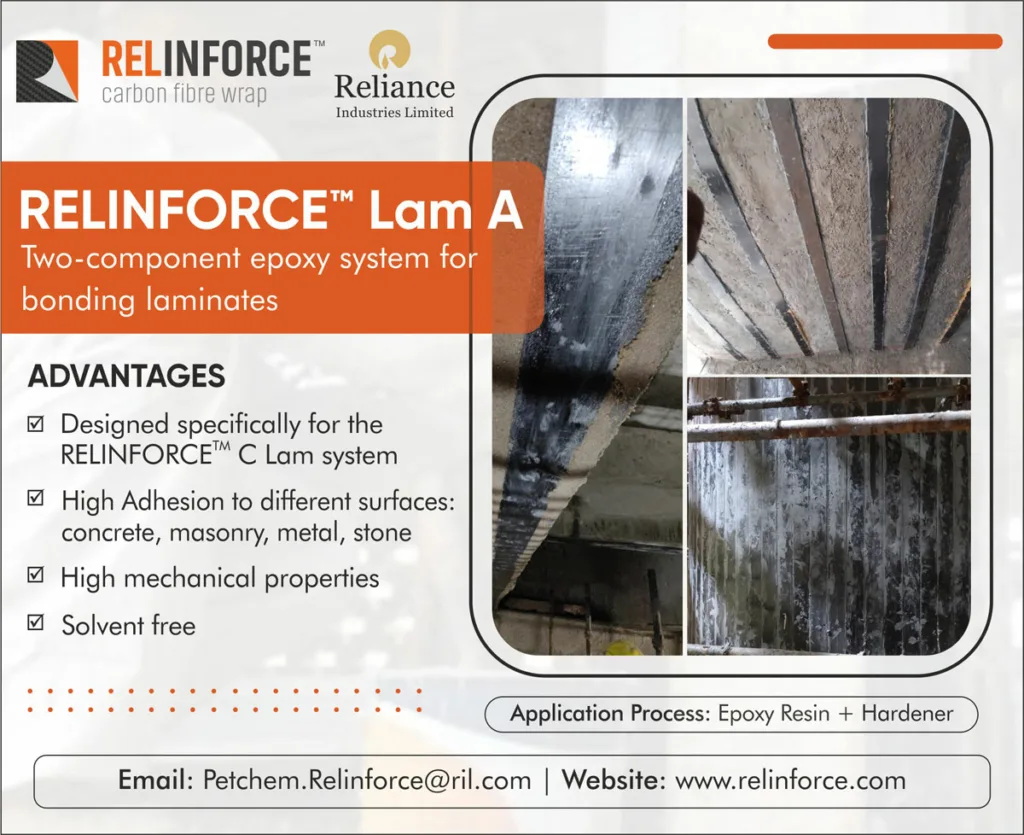

Bonding laminates refers to the process of joining two or more layers of materials, typically thin sheets or panels, to create a composite structure. Epoxy systems are often preferred for bonding laminates due to their unique properties and benefits. Epoxy systems provide excellent bonding strength, allowing for durable and long-lasting bonds between laminates. They can withstand significant loads, including shear, tensile, and impact forces. The epoxy system used for bonding laminates may vary depending on the application requirements and the type of laminates being bonded. The selection of the right epoxy resin system is important for project execution, RELinforce™ Lam A , manufactured by Reliance Composite is one such product. It is a two-component epoxy-filled adhesive system with excellent mechanical properties. The contrasting colour between base and hardener allows easy control of the correctness of the mixing.

RELinforce™ Lam A consists of two separate components: epoxy resin and a hardener. These two components are mixed together in a specific ratio just before application to initiate the curing process. The two components include:

1. Epoxy Resin: Epoxy resin is one part of the two-component system. It is a viscous liquid or semi-solid material that forms the base of the adhesive. The epoxy resin provides adhesive properties, such as bonding strength, adhesion to different surfaces, and chemical resistance.

2. Hardener: The hardener is the second part of the two-component epoxy system. It is a catalyst or curing agent that, when combined with the epoxy resin, triggers a chemical reaction known as curing or polymerization. The hardener initiates the cross-linking of the epoxy molecules, transforming the adhesive from a liquid to a solid state.

When the epoxy resin and hardener are mixed in the prescribed ratio, a chemical reaction begins, leading to the formation of a strong, durable bond between the laminates. After application, the two-component epoxy adhesive cures over time, reaching its full bonding strength.

Advantages of RELinforce™ Lam A

- Designed specifically for the RELINFORCE C Lam system

- High Bond Strength

- Compatible with a wide range of laminate materials

- Controlled Curing Process

- Chemical Resistance

- Temperature and Moisture Resistance

- High mechanical properties

- Easy Application

- Aesthetic Appeal

Applications of RELinforce™ Lam A

- Structural adhesive with high wettability, suitable for bonding pultruded laminates

- Suitable for application on vertical or overhead surface

RELinforce™ Lam A epoxy system provide exceptional bonding strength, resulting in strong and durable bonds between laminates. They offer high shear and tensile strength, ensuring reliable and long-lasting adhesion.

About Relinforce Composite solution

RELinforce™ Lam A is manufactured and supplied under Reliance India’s Composites Solution Division. Reliance Industries Limited is India’s largest private and one of the most profitable private sector companies and the first Indian Fortune 500 company. The company composite division’s product range includes Epoxy Putty, Carbon fiber laminates, Carbon fiber anchor, Carbon Fabric for FRP Structural Strengthening, Carbon fiber Grid, Epoxy Injection Grout etc. used for structural strengthening, repair and rehabilitation.

To know more about the product, visit – https://www.relinforce.com/