As global attention shifts toward reducing operational energy in buildings, materials that enhance passive performance are becoming essential. Phase-change materials (PCMs) are emerging as a highly effective solution because they store and release thermal energy to stabilise indoor temperatures. This blog explores how PCMs work, why they are important for modern construction, their applications, benefits, challenges, and future potential for energy-efficient buildings.

Why Energy Efficiency in Buildings Matters

Buildings account for more than 30% of global energy consumption and contribute substantially to CO₂ emissions, making energy-efficient construction a priority. A large portion of this energy is spent on heating and cooling, especially in regions with fluctuating or extreme climates. Improving a building’s envelope through advanced materials like PCMs can reduce energy demand while enhancing comfort, offering a practical and sustainable alternative to depending solely on HVAC systems.

What Are Phase-Change Materials (PCMs) and How They Work

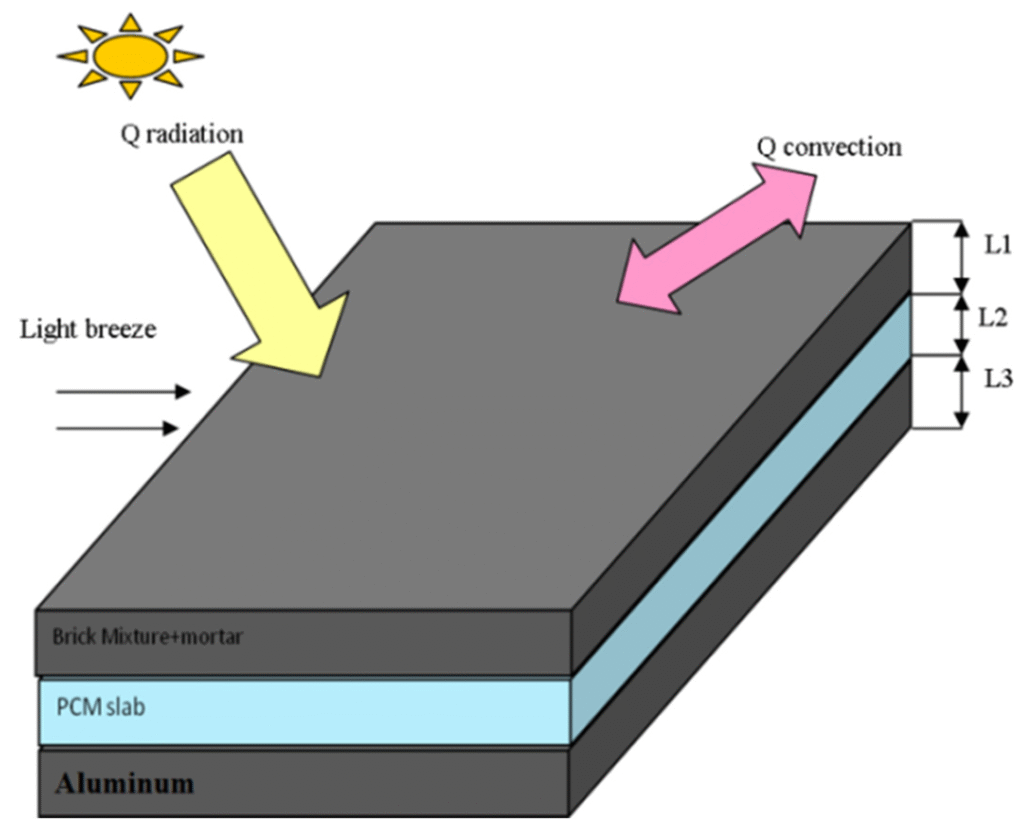

Phase-change materials are substances that absorb or release significant amounts of heat as they transition between solid and liquid states. When temperatures rise, they melt and store excess heat; when temperatures drop, they solidify and release stored energy back into the building. This cyclical behaviour helps maintain steady indoor temperatures, reduces peak loads, and supports energy savings. Key performance factors include melting point, latent heat capacity, thermal conductivity, and long-term durability.

Applications of PCMs in energy-efficient building design

- Integration into building envelope components: e.g., PCM-enhanced gypsum boards, PCM-infused concrete/mortar, PCM in façade elements.

- Glazing and smart envelope use-cases: PCM glazing or smart windows that incorporate phase-change layers.

- Case/data example: A study found that gypsum boards with ~30% PCM achieved up to ~12.8 % reduction in annual energy consumption and ~22.3 % reduction in net annual energy use compared to baseline.

- Mention that PCMs can be used in both hot-climate cooling mitigation and cold climate heating support (depending on design).

- Brief UK/European context: highlight that buildings in the UK/EU are increasingly required to meet stricter energy performance, so PCM solutions align with emerging regulations and sustainability goals.

Benefits and performance outcomes

- Reduced energy consumption (heating/cooling) and peak load reduction. For example, one review indicates PCM integration improved thermal comfort by up to 60 %, heating electricity savings of up to 100 %, and cooling electricity up to 53 %.

- Improved indoor thermal comfort and reduced temperature swings, which can enhance occupant well-being and reduce HVAC runtime.

- Potential for smaller HVAC equipment sizing and lower life-cycle operational costs (if envelope loads are reduced).

- Contributes to sustainability goals by reducing embodied/operational carbon when properly selected.

- The actual performance depends heavily on design, climate zone, PCM selection and integration method.

Challenges & practical considerations

- Material and integration challenges: PCMs often have low thermal conductivity, risk of leakage (if liquid) or volume change, durability concerns.

- Structural property trade-offs: e.g., high PCM content in mortar or concrete may reduce mechanical strength or increase cost.

- Selection of melting temperature: needs to align with building climate and comfort zone; incorrect selection reduces effectiveness.

- Cost-effectiveness: initial cost of PCM materials and encapsulation may be higher; ROI depends on energy cost savings, climate, envelope design.

- Fire safety / regulatory concerns: organic PCMs may be flammable, need to comply with building codes.

- Implementation challenges: retrofits vs new build, integration into building services, behaviour over long term (cycling fatigue).

- Mention UK-specific considerations: climate variability, building regulations (e.g., Part L), occupant usage patterns.

Conclusion

Phase-change materials offer a powerful pathway to improving building efficiency by reducing energy use, stabilising indoor temperatures, and supporting long-term sustainability goals. Their effectiveness depends on selecting the right material, matching it to local climate conditions, and integrating it intelligently into the building envelope. As regulations tighten and environmental awareness grows, PCMs are poised to become a central feature of next-generation high-performance buildings. Encouraging architects, engineers, and builders to adopt PCM-based solutions early in the design phase can amplify energy benefits and deliver long-lasting value.

Info- pmc.ncbi.nlm.nih, , mdpi.com, arxiv.org, sciencedirect.com, sustainenergyres.springeropen.com, energy.gov