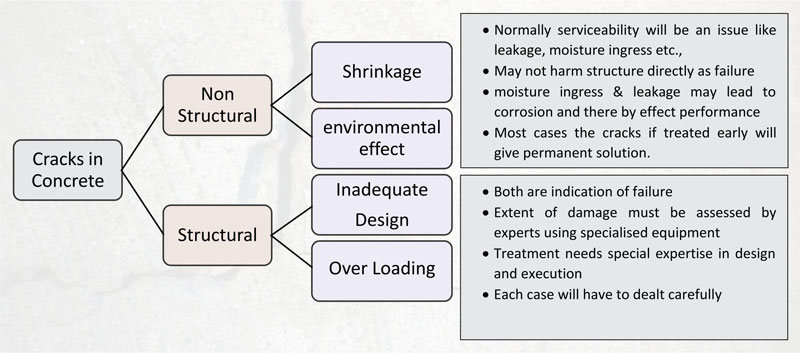

Cracks in concrete slabs are caused by several variables including shrinkage, environmental effect, inadequate design and overloading from seasonal temperature changes, and sun exposure. Concrete cracks can be sorted into two broad classifications, structural and non-structural cracks. In this article we have focused on how non-structural cracks should be monitored and repaired, so they don’t get worse.

Non-structural cracks in concrete slabs

Typically, non-structural cracks appear during the green state of concrete or during early stages of hardening. Different types of non-structural cracks include;

Plastic Shrinkage Cracks

Plastic shrinkage occurs in freshly mixed concrete, with loss of water by evaporation from its surface, after placing and before hardening of the concrete.

This can lead to Plastic Shrinkage Cracking if the rate of evaporation is higher than that of the bleeding water rising to the surface of the concrete.

If the volume of fresh concrete (V), Vol. of Cement (VC), Vol of aggregates (VA), Volume of water (VW) and part of Water V’W

V = VC + VA + VW

Let us say part of VW will be evaporated let us say (∆VW) now the volume of concrete will be

V1 = VC + VA + VW – ∆VW

It is obvious that the new volume of concrete V1 < V

That means concrete has reduced in its volume, this is the shrinkage in volume concrete will initiate cracks in concrete.

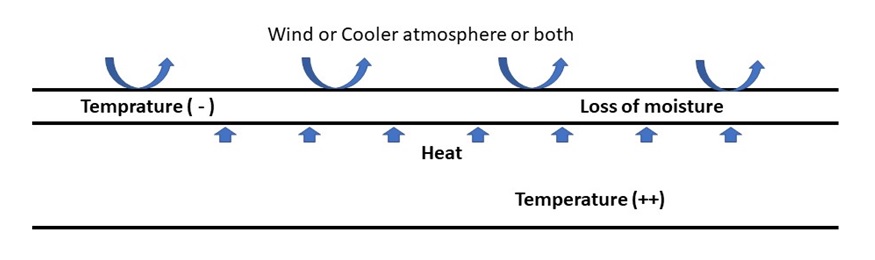

These cracks start appearing when the concrete is moving towards a hardening state – concrete will become soft. They start appearing slowly irregularly in most cases starting at surface level then may go deeper. High ambient temperatures, wind blowing across the surface of the slab & heat of hydration will influence these crack formations. As cement content increases in concrete the possibility of shrinkage cracks may increase due to heat of hydration. Basically any influence that evaporation of moisture will be the reason behind plastic shrinkage.

Thermal Cracking of Concrete

Thermal cracking occurs due to excessive temperature differences within a concrete structure or its surroundings. The surface contraction due to cooling is restrained by the hotter interior concrete that doesn’t contract as rapidly as the surface. This results in the cracking of concrete.

Higher temperatures within the concrete mass due to any reason would trigger moisture loss on the surface of freshly laid concrete slabs, it appears slightly later than 2 – 4 hours after concreting when enough heat is accumulated due to heat of hydration. The possibility of Thermal Cracking is observed more in the slabs made with higher cement content or the concrete that are designed for very early strength. Thermal cracks are also observed often when concreting is happening on a night where ambient temperature is very low and the temperature difference between the middle of slab thickness & top surface goes higher. Natural phenomenon the heat tries to radiate towards lower temperature. These types of cracks are observed more often in construction of Rigid Pavement, as concrete there will normally M45 or so with cement content not less than 390KG along with that there would be a higher depth of concrete.

The other place we may see this kind of cracks are the raft foundation.

Methods of Handling early cracks in Concrete

There are Preventive Measures for early handling cracks in concrete, each of them is given below.

- Curing

Start early curing as early as 3 hours in summer and about 5 hours in other months. However, in RMC please ensure that there is some bleed water on top of the Concrete surface – in case it is not found we should spray some water.

- Wind barrier

Having physical barrier around the slab being done to a height of around 750MM to 900MM all along the edge of Concrete slab being done. It could be Metal sheet fixed vertically around the edge of the slab or it could be 75% agricultural shade net all around so that it would break the wind speed. Special care should be taken when we are using metal sheets as wind barriers as there would be lateral pressure developed and proper support against lateral sway should be given.

- Secondary Compaction

This is a process in which we compact the concrete after about 60 to 90 minutes so that the initiation of plastic shrinkage is nullified.

How to do it?

- The fresh concrete should be compacted properly and finished.

- Wait till the bleed water is dried up or the concrete becomes firm enough for a lightweight person to walk on it without sinking his/her foot.

- Then from the area of fist pour of concrete the person should mildly tamp the concrete so that a little cream of cement slurry comes out. This tamping should be done in lines with a small overlap of tamping marks.

Please note: a) if the concrete is too dry we can sprinkle a little water and tamp. b) if we observe cracks forming, we need to use dilute cement slurry to reactivate binding to pack the cracks that are forming.

The details of a tamping tool and the key sketch of tamping rows, you can view the video-

These days Electric operated plate vibrators are also used. Care should be taken on the frequency of vibration and the formwork stability.

What to do after Non-Structural Cracks have appeared?

The immediate solution to sort out Plastic Shrinkage cracks or Thermal Cracks are the same.

There are 2 stages of handling this problem.

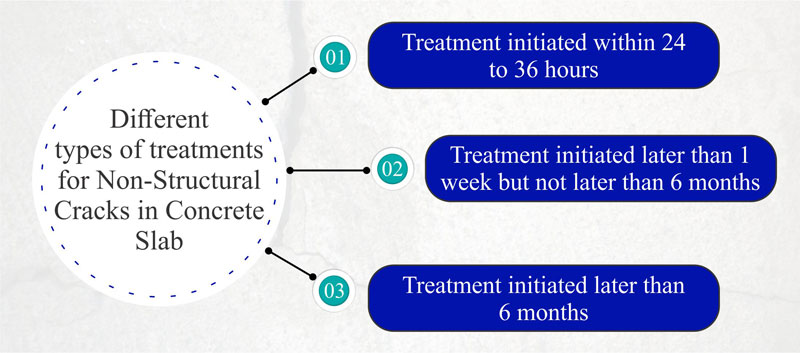

- The cracks are observed, and treatment starts with 24 to 36 Hours.

- The Cracks are observed and treatment initiated later than a week or 10 days or more.

Different types of treatment and steps to execute them are discussed below.

Case 1. Treatment initiated within 24 to 36 hours.

Note: Cleaning of the cracks with soft brush, allowing the diluted SBR solution to percolate into the crack followed by tamping and finishing will be very critical to get good results. Details of Latex SBR are given at the end of this document.

Case 2. Treatment initiated later than 1 week but not later than 6 months.

Note: Cleaning of the cracks with Hard brush, allowing the diluted SBR solution to percolate into the crack followed by tamping and finishing will be very critical to get good results. If the crack is wider we can use very fine sand that can be mixed with the slurry to ensure the hardened material is durable. Details of Latex SBR are given at the end of this document.

This crack treatment is for mother slab only if the cracks are on screed concrete (weather proofing course) the cracks need to be widened to about 5-6mm and mortar made with diluted Latex solution to be applied at the end, finishing is done.

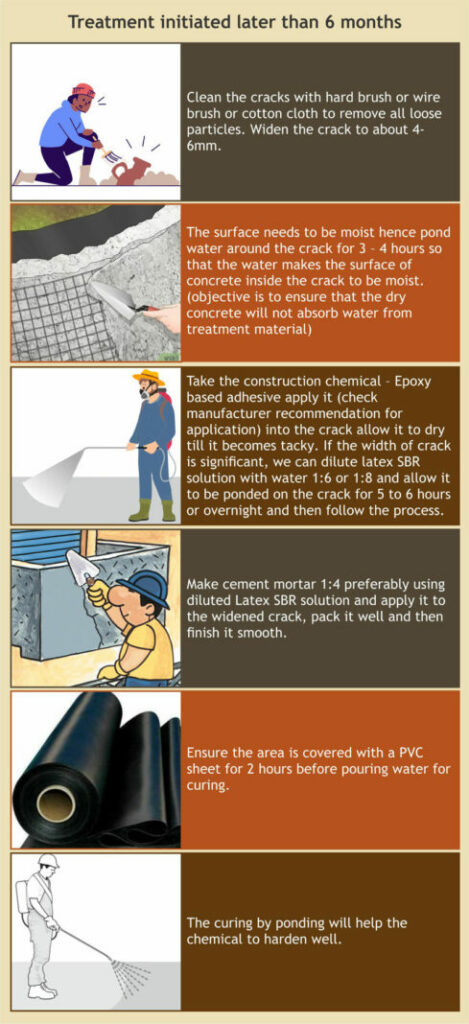

Case 3. Treatment initiated later than 6 months.

Details about Latex SBR

The term SBR stands for Styrene-Butadiene Rubber when the source of this is from the rubber latex it is called LATEX SBR. This is a polymer that;

- induces Better adhesiveness to mortar.

- Improves the cohesiveness of mortar

- Improves the flexural behaviour of the mortar.

The Latex SBR is available in the market supplied by many Construction Chemical companies.

Conclusion

Complete guidance on the type and prevention treatments of non-structural cracking is given above. Following these details, you could improve the durability and wear of a surface, reduce permeability and prevent a corrosive environment from developing in the concrete slab.

Authored by – ConCroc