For more than 40 years, glass fibre reinforced concrete (GFRC) has been a substantial advancement in the technology, economy, and aesthetics of the global building sector. For architects and engineers, GFRC is one of the most adaptable building materials available. Its unique structure causes it to have more complex qualities than regular concrete. Numerous factors affect the qualities and behaviour of GFRC as well as the precision of the production process.

These factors include the water-cement ratio, porosity, composite density, inter-filler content, fibre content, orientation and length, and type of cure. GFRC weighs significantly less than conventional pre-cast concrete products since it can be made as thin as 6 mm. The utilisation of premix, spray-up, and hybrid GFRC technologies, along with the advancement of 3D printing technology may create intricate architectural forms and entire buildings with exceptional dependability. The GFRC has been impacted by the cost and popularity of self-cleaning, ecologically friendly panels for industrial building. Recently there has been an increase in the usage of glass fibre in the High-Performance Concrete (HPC) class, which is known for its exceptionally high mechanical performance, durability, workability, and aesthetics. International standards developed in Europe, America, Asia, and Australia, govern the design and production of GFRC products. More than 100 countries produce GFRC.

METHODS

There are two primary methods for producing GFRC, spray-up and pre-mix being the most widely used. The mortar is created independently of the fibres throughout the spray-up procedure, and the two are only combined at the spray gun’s jet. The glass fibre strands are chopped inside the spray cannon to the desired size which is typically between 25 and 40 mm and accounts for 4-5 percent of the weight of the mixture in total. Spraying produces a thin coat that is as thin as feasible using a fibre-free matrix. To ensure integrity the following layers of matrix with fibres are placed swiftly. It receives the mixture to toughen after the majority of the GFRC is layered on top of it. The typical thickness of the covering layer varies based on the kind of surface treatment between 3 and 5 mm. Approximately 4-6 mm of material is deposited with each spray gun pass; however, corners and intricate designs require careful application of an appropriate layer thickness. In order to remove any air that was retained in the mixture and to impregnate the fibres within the mortar, the construction was finally compressed using a cylindrical roller or a float. Layer thickness is measured using a depth gauge or template in order to ensure that GFRC is the minimum required. Pre-cut glass fibres ranging in weight from 2-4 percent (often 3.5% to 6%), are mixed with cement matrix in the pre-mixture and casting process of producing glass fibre reinforced composites. Pre-cut fibres are typically 6 to 12 mm long however longer fibres limit the workability of the mixture. For maximum workability chopped fibre strands are introduced into the matrix through a low-speed mixing regime after the matrix is created in a high-shear mixer. This makes it easier for them to disperse at the maximum volume content that is practical while causing the least amount of fibre damage. Pre-mix GFRC production can include a number of processes, including pressing, shotcreting, and injection and vibration.

Spray up process

Pre–mixture and casting process

CURING

The curing stage of conventional concrete technique is essentially the same. Furthermore, the negative consequences of incorrect water curing are far more noticeable in the GFRC product. Increased drying and a decrease in strength may result from the GFRC’s low thickness and larger surface area. Long-term moist curing is frequently not necessary due to the polymer concentration. The fresh mixture retains its internal moisture content due to the small concentrations of acrylic polymers that inhibit its evaporation. To guarantee that the GFRC develops sufficient strength for the element to be securely removed from a mould, sudden and rapid drying-out or significant temperature changes must be avoided. GFRC components are usually stripped between 16 and 24 hours after casting, usually the next day. Although better concrete will always result from longer cure times most concrete tends to strip shortly after casting.

PROPERTIES

The composite’s structure affects the characteristics of fibre-reinforced cementitious materials. Therefore, an internal structure analysis of these composites is necessary in order to forecast their performance under different loading circumstances. The following three factors need to be taken into account:

- The structure of the bulk cementitious matrix.

- The shape and distribution of the fibres.

- The structure of the fibre–matrix interface.

MATRIX

There are two forms of bulk cementitious matrix: paste/mortar (cement/sand–water mix) and concrete (cement–sand–coarse aggregate–water mix), which are distinguished by the particle filler (aggregate) that they include. The thin sheets that are primarily used for cladding are often coated with glass fibre reinforced concrete pastes or mortars. The main reinforcing element in these applications is fibre which typically makes up 5–15% of the total volume. Such composites must be manufactured using specialised production techniques.

FIBERS

Reinforcing arrays can be broadly classified into two categories: discrete short fibres, typically less than 20 mm long, that are incorporated into the matrix by means like spraying and mixing and continuous reinforcement in the form of long fibres that are incorporated into the matrix by means of filament winding or the lay-up of layers of fibre mats. Depending on how the fibres are distributed within the matrix, the reinforcing array can be further divided into random 2D and 3D categories. Three-dimensional (3D) random reinforcement is the first type. This happens when concrete is combined with fibres and then poured into shapes. Fewer fibres are genuinely able to withstand tensile loads that arise in a particular direction due to the random and 3D orientation. This degree of fibre reinforcement requires extremely high fibre loads and is highly inefficient. Only 15% of the fibres are usually orientated appropriately. The second level consists of two-dimensional (2D) random reinforcement. This is the content of spray-up GFRC. Within a narrow plane the fibres are arranged randomly. The fibres lay flat once they are sprayed into the moulds, reinforcing their shape. In most cases, between 30 and 50% of the fibres are orientated properly.

THE STRUCTURE OF THE FIBRE–MATRIX INTERFACE

In the area of the reinforcing inclusion, cementitious composites exhibit an interfacial transition zone where the paste matrix’s microstructure differs significantly from the bulk pastes, further away from the interface. Depending on the fibre type and production method, this transition zone’s characteristics might vary greatly over time. A bundled filament should be created when taking into account how the microstructure is developing in the transition zone. With bundled filaments, only the external filaments typically have direct access to the matrix.

MECHANICAL PROPERTIES OF GFRC

COMPRESSIVE STRENGTH

Fibres added to concrete mixtures have been shown to boost the compressive strength of the material however additional fibre addition has been shown to gradually diminish certain characteristics of strength.

MODULUS OF ELASTICITY

The behaviour of the composite’s elastic modulus is determined by the density and properties of the transition zone in heterogeneous and multiphase materials like concrete. The elasticity modulus of concrete remains unaffected by the addition of fibres, as demonstrated by the results of the laboratory tests. According to reports, there is generally only a slight decrease in the concrete’s modulus of elasticity when the glass fibre percentage is minimal. STRESS–STRAIN CURVE

Many factors including the type of aggregate, loading rate, and fibre lengths, might influence stress-strain behaviour. The climbing component of the stress-strain curve is significantly impacted by GFRC as shown in Figure while the descending part of the stress-strain curve is crucial under compression loads.

FLEXURAL STRENGTH

The increase in flexural strength of concrete is influenced by glass fibres. When comparing plain concrete specimens to those with increased fibre content, Figure shows that the flexural strength of the concrete increased albeit not significantly. The fibres help to strengthen the concrete’s load carrying capacity by preventing cracks from spreading and reducing the likelihood of a sudden collapse of the building.

PHYSICAL PROPERTIES OF GFRC

DRYING SHRINKAGE

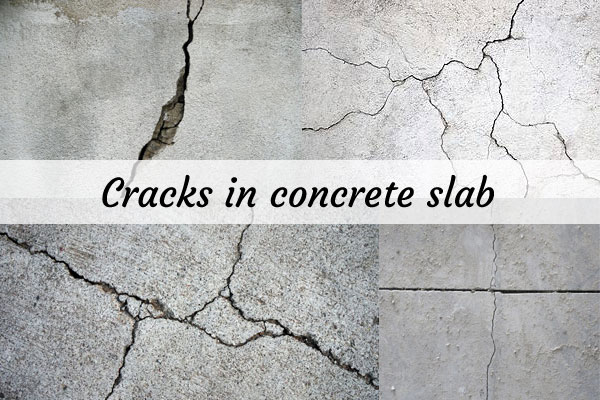

Drying shrinkage significantly impacts the concrete’s durability and structural performance. Although the process of cementitious material shrinkage is complicated, the amount and kind of aggregate as well as the water to cement ratio mostly determine overall shrinkage. These factors also affect drying and contribute to the simultaneous spread of numerous microcracks. In addition to causing corrosion and freezing damage, shrinkage in concrete structures can also significantly reduce the service life of concrete. Alkali resistant glass fibres encourage multiple cracks and narrow crack widths while effectively reducing constrained shrinkage cracking in concrete.

CREEP

Concrete has a low tensile strength and poor strain capacity making it a fragile material that is easily cracked. Because they let in hostile agents these fissures can shorten a structure’s lifespan. As a result, the way that crack openings change over time affects how long concrete will last. The method of applying GFRC must be considered in terms of creep and shrinkage. Glass fibre is added to mortar mixtures by pneumatic spraying and this results in a notable alteration to the compositions involved in binder consumption during pouring. There may be a creep strain resulting from this.

POROSITY, CHLORIDE PENETRATION RESISTANCE AND ELECTRICAL RESISTIVITY

Migrating ions allow the many micropores in concrete a multi-phase material to be transmitted. Thus, measuring resistivity provides a conclusive method of examining the microstructure of concrete. The water-to-cement ratio, the composition of the concrete, the admixtures, the curing conditions and the humidity all affect how resistive the concrete is. All of these effects could thereby raise the possibility of steel rebar corrosion in concrete. Figures make this impact quite evident. Furthermore, electrical current and corrosion risk can both rise when chloride is present in a concrete building. Alkali resistance less chloride seeps into concrete according to GFRC improving corrosion resistance. When compared to a plain concrete specimen Figure shows that a rise in fibre content significantly decreased the chloride permeability of the concrete. As a result, one of the most crucial qualities of concrete is its durability can be enhanced while concrete constructions are in use.

APPLICATIONS AND LATEST DEVELOPMENTS OF GFRC

The unique structure of GFRC gives it more complex qualities than regular concrete. It has an appropriate moulding and a sturdy long-lasting construction because of its structural qualities. Furthermore, it is inexpensive due to its quick installation time, ease of handling and portability. It is eco-friendly and has the ability to scatter or absorb sound. One of the most important outcomes of these attributes has been the adaptability of GFRC. GFRC is extensively and consistently utilised in engineering (i.e. permanent formwork, utilities, acoustics, bridges and tunnels, highways, water and drainage) architecture (i.e. cladding, mouldings, landscaping), and building (i.e. roofing, walls and windows, rehabilitation, foundations and floors). For the first time ever, self-cleaning, ecologically friendly panels for an industrial structure were created in Turkey using a special glass fibre reinforced concrete technology. Given that the building is located in the centre of a refinery, self-cleaning GFRC panels will be subjected to the toughest environmental conditions, including emissions of NOx and SOx.

FINAL COMMENTS

For engineers and architects, GFRC is one of the most adaptable building materials available. The building business has benefited greatly from its substantial contributions to economy, technology, and aesthetics. To better understand the mechanical and physical features of GFRC a thorough review that examined popular techniques of GFRC production and the compatibility of emerging technologies was conducted. In general, adding glass fibre raises the compressive strength however adding too much fibre reduces the strength because of decreased workability. The addition of modest volume fraction fibres to the concrete does not significantly increase its modulus of elasticity. Due to a rise in the aspect ratio of the fibres which causes an increase in pull-out and energy absorption of the GFRC, glass fibres have a beneficial influence on the stress-strain curve of GFRC and flexural strength. In general, GFRC has a longer service life than conventional concrete because it reduces permeability, corrosion (particularly AR-glass fibre corrosion), and the spread of micro cracks. GFRC weighs between 50 and 70 percent less than conventional concrete. Self-mixing, however is challenging (special substance required). Because of the fibreglass, additives, and acrylic co-polymer, it is more expensive than regular concrete but, as technology advances, this disparity may be significantly altered. In engineering, construction, and architecture applications, GFRC is often and consistently utilised. In addition, digital technologies can be used to create intricate forms, ornamental materials, and entire structures. An additional valuable resource is glass fibre reinforced composite (GFRC) which is used in high-performance concrete applications readily dyeable surfaces and self-cleaning environmentally friendly panels. As such, there exists a large body of practice-based GFRC applications but very little research to back them up. Further research can be conducted to improve the properties of GFRC in order to meet the growing requirements for its use in practical applications.

About the author

The author is the Managing Director at Skanda Group of Constructions. He is an experienced Civil Engineer with a demonstrated history of working in the construction industry. He is skilled in AutoCAD, Construction, Management, Concrete, and Structural Analysis.