Head (Technical & Marketing),

STP Ltd.

The rising demand for waterproofing systems is fuelled by rapid urbanization, infrastructure development. The increasing spending by the government on private and public infrastructure projects, such as roads, power stations, water treatment plants, airports, bridges, hospitals, and schools, is further influencing the demand for waterproofing solutions. As the industry expands, building contractors need to offer their customers longer lasting, high-performance solutions to stay competitive. High-quality waterproofing is essential to preventing structural damage and maintaining a healthy, comfortable environment. To address the growing demand of waterproofing, there has been an advent of different innovative waterproofing solutions in India.

Advents in waterproofing solution in India

Thermo PolyOlefin

Popularly TPO, is an UV stable and 100% recyclable material

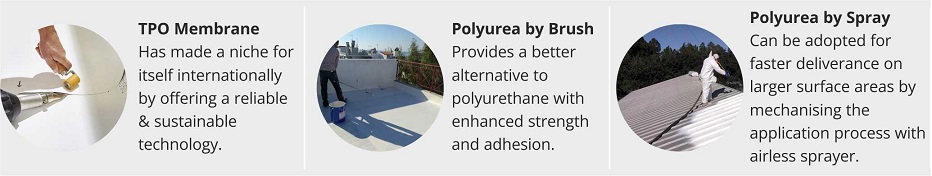

Strict REACH norms of EU and reliability of thermo-polyolefin had in past, established the position of TPO membranes. Off late, it was being imported and always posed an investment challenge to the Asset Owners. Now, as a delight, progressive entrepreneurs have started manufacturing indigenously, and placed its distributed through competent channels. This will surely ensure that structures built today, are able to trend-set a new generation of assets having much higher sustainability standards. Needless to say, product selection is always a marriage between Technology and Affordability.

Anchoring of Membranes

Preformed non-bituminous membranes has long since entered the domain of waterproofers. Laid loosely or fully bonded (top-side or bottom-side), seam joining and proper termination is critical to its success and this asks for skilled manpower equipped with modern accessories. Self-adhesive selvages, Double-side tapes, hot-air welding, mechanical anchoring, chemical / cementitious adhesive, etc. are adopted as many of the joining methods for installation of these pre-formed membranes. To seriously gain from these advanced technologies, it is important that collectively, the construction industry sets a path for skill enhancement of application workers in this sector.

Polyurea

Is obtained by reacting an isocyanate with multifunctional amine

Since long the essence of liquid applied membranes was realised and has gradually started to sideline traditional system of hot applied preformed bituminous sheets. Various varieties of polyurethane has been developed and time-tested. Water-based single component, solvent-based single component, two component aromatic, solvent free two component aliphatic and plethora of formulations are offered by leading manufacturers. Yet, certain inversely related properties cannot be stretched beyond a certain point while dealing within the realms of a given chemistry. Demands for better toughness and substrate bonding without compromising its elongation at break, stretched the imagination of researchers. They explored new hardener chemistries which further extended the polymerisation of isocyanate in order to deliver a much more heavy duty, yet flexible material – Polyurea. For waterproofing applications, it’s strength capability allowed service providers to do away with the requirement of sandwiching a liquid applied waterproofing membrane with fibre-mesh or geotextile fabric, which resulted in simplification and reduction of labour cost.

“Product Selection is always a marriage between Technology & Affordability”

This innovative break-through has ensured that its does not strike hard on the pocket of the asset owner, against offering a system that is much more reliable. Today, several leading project management consultants and capital investors are opting for the brushable grade of polyurea which is easy on the budget, in terms of labour cost. As historically proven, a liquid membrane does not ask for high and specialised skill-set from an application labourer. An experienced and seasoned supervisor is adequate to ensure the an effective, defect-free system is delivered.

About the Author

Anupam Shil is working with Head of Technical & Marketing Services at STP Limited. The author has 25+ years of working experience with several global and indigenous companies offering a wide range of engineering products and services to the Industrial and Infra sector.

His extensive area of expertise incorporates providing protective coating solutions for concrete, metals and pavements for long term durability. Several technical papers and articles written by him have been published in Industry magazines and Engineering Journals. Has delivered technical lectures in conferences organized by IEI, ICI, BMTPC, Govt. & Pvt. Organizations, Educational Institutions to name a few.