Having the right equipment and systems can make or break any construction project. Using the ideal solutions can increase the productivity, safety, and cost-effectivity of your ongoing and upcoming activities.

Of the various construction processes, handling and storing bulk materials—gravel, sand, cement, and other granular products—is one of the most challenging. Fortunately, advancements in industrial processes, including construction, continue to evolve.But with multiple things to consider, how do you know which one works best for you? Let’s explore the latest technologies in bulk material handling and storage and determine how they can transform your project sites.

Unique Storage Solutions

Before discussing how to get bulk materials flowing, let’s talk about keeping them organized and protected. Here’s where innovative storage solutions come in:

· Advanced Bulk Storage Buildings

Don’t underestimate the power of a well-designed building. Modern bulk storage buildings incorporate features like ventilation systems to control moisture and dust, fire suppression measures for safety, and efficient loading and unloading access for maximized productivity.The latest storage silos also utilize advanced materials like fiber-reinforced polymers (FRPs) for exceptional strength and corrosion resistance. They also boast integrated sensors that monitor material levels, ensuring you never run out mid-pour.

· Collapsible Containers

Need a flexible storage solution? Collapsible containers offer the best of both worlds. When empty, they fold flat for easy transport and storage. But when needed, they quickly pop up into sturdy containers perfect for sand, gravel, or even tools and equipment.

· Smart Stockyard Management Systems

Gone are the days of manually climbing silos to check inventory. Smart stockyard management systems use a network of sensors and cameras to provide real-time data on material levels.

· Automated Inventory Management

Imagine a system that automatically reorders materials when they dip below a certain level. That’s the beauty of automated inventory management systems. These software programs integrate with your storage systems and ordering platforms, eliminating the risk of stockouts and streamlining your purchasing process.These advanced systems minimize material damage and optimize space utilization within your facility. They also promote proactive inventory management. This proactive approach keeps your operation running smoothly and minimizes downtime.

Automated Storage and Retrieval Systems

Instead of having workers manually load and unload materials from storage buildings, silos, or bins, you can have a fully automated system that does all the heavy lifting for you. Automated storage and retrieval systems (AS/RS) use computer-controlled machinery to manage the storage and retrieval of bulk materials efficiently. Here are a few examples of how AS/RS solutions are applied in construction:

· Stacker Crane Systems

These are commonly used at construction sites and building material yards to automatically store and retrieve palletized loads of bricks, blocks, bagged cement, and other palletized materials from multi-level racking systems.

· Vertical Lift Modules (VLMs)

VLMs allow compact, high-density storage of smaller construction materials like tools, fasteners, and electrical components within a minimal footprint on job sites or warehouses.

· Carousel Systems

Enclosed horizontal carousels provide secure, automated storage and dispensing of high-value construction tools, equipment, and supplies at work sites.Automated storage and retrieval systems (AS/RS) can be used for bulk materials like gravel, sand, cement, rebar, and other building supplies. They help maximize bulk density storage, reduce manpower needs, and improve inventory control and accuracy.

Material Transportation

Gone are the days of relying solely on dump trucks, backhoes, and concrete transit mixers to streamline the construction process. A variety of options cater to different materials and site layouts, such as:

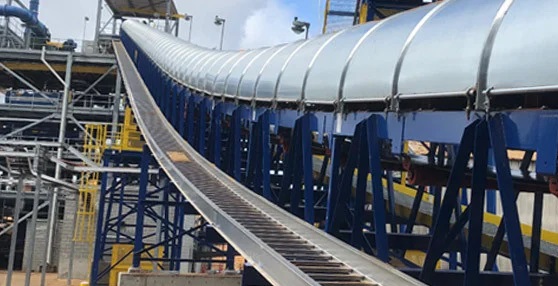

· Conveyor Systems

Imagine a tireless worker tirelessly ferrying bulk materials across your site. That’s the magic of a conveyor system. These come in various forms, from conveyor belts for hefty loads like sand and gravel to screw conveyors for finer materials like cement. Their modular design allows customization, letting you create intricate networks that snake around obstacles and deliver materials precisely where needed.

· Pneumatic Conveying

For those hard-to-reach nooks and crannies, consider pneumatic conveying systems. Pneumatic conveyors use compressed air to propel materials through enclosed tubes—perfect for powdery materials like fly ash or even lightweight aggregates. They offer a clean and efficient solution, especially when dust control is a concern.

· Automated Guided Vehicles (AGVs)

Ever dreamt of self-driving dump trucks? AGVs make that dream a reality. These robotic vehicles and machines navigate pre-programmed routes, autonomously transporting and retrieving bulk materials like gravel, sand, or aggregate stored in dense block stacking patterns around your site. They’re ideal for repetitive tasks, freeing up your human crew for more complex jobs.Using these innovative bulk material handling systems can significantly reduce labor costs and improve safety by minimizing human intervention.

Automation and Data Analytics

Innovation isn’t just about fancy gadgets. It’s also about optimizing automation and data for efficient operations. Advanced monitoring and analytics solutions make this possible by collecting and analyzing data from various sensors and equipment throughout your facility.Imagine being able to track material flow and levels in real-time, preventing costly delays caused by missing or lacking raw materials. Predictive analytics and machine learning algorithms can also monitor equipment performance and maintenance needs while identifying potential bottlenecks or issues before they occur. Having these systems provides invaluable insights and recommendations to help you streamline your operations and make data-driven decisions.

Investing In the Future

Time is money in the construction industry; that’s why efficiency reigns supreme. If there’s one way to future-proof your organization, automated systems, and advanced bulk material handling equipment are your best tools. Using these cutting-edge solutions may entail a significant investment. However, they offer invaluable returns by optimizing construction processes and making your projects more profitable. Investing in these technologies makes you work smarter, not harder. And it’s what keeps you ahead of the curve in the highly competitive construction industry.