ESD protection plays a vital role when working with sensitive electronic components and assemblies. ESD stands for electrostatic discharge and refers to sudden releases of built-up static electricity. The discharge of static electricity can cause damage to electronic equipment, including microchips, circuit boards, and other electronic components. Even a small electrostatic discharge that is imperceptible to humans can generate enough energy to disrupt or destroy sensitive electronic devices, leading to malfunctions, data loss, or complete failure.

How does electrostatic discharge occur?

ESD stands for Electrostatic Discharge. It refers to the sudden flow of electric current between two objects that have different electrical potentials. Static electricity is generated when certain materials are rubbed or separated, causing an imbalance of electric charges on their surfaces. When two objects with different electrical potentials come into close proximity or make contact, the built-up static charge can be discharged in the form of an electric current, resulting in an electrostatic discharge.

Causes;

- Static electricity

- Electrostatic induction

Impact;

- Electrostatic Shock

- Fire and Explosions

- Latent defects

ESD can occur in various facilities and can have both harmless and damaging effects. In everyday life, minor ESD events are common and often go unnoticed, such as the small shock you may experience when touching a doorknob after walking on a carpet. However, in industries and environments where sensitive electronic components are present, ESD can be a serious concern.

To mitigate the risks associated with ESD, various measures are implemented, including the use of ESD flooring products manufactured to dissipate static charges.

What is ESD flooring?

ESD flooring, also known as Electrostatic Discharge flooring, is a specialized type of flooring designed to control and prevent the buildup and discharge of static electricity. It is commonly used in environments where sensitive electronic components, equipment, or devices are present, such as laboratories, manufacturing facilities, cleanrooms, data centers, and server rooms.

Static electricity can be generated through various activities, such as walking or moving objects, and it can pose a significant risk to electronic devices. When an electrostatic discharge occurs, it can damage or destroy electronic components, leading to malfunctions, data loss, or even fires in extreme cases. ESD flooring helps to dissipate static electricity safely, preventing such damage.

ESD flooring typically consists of a conductive or static-dissipative material that allows the controlled flow of electric charges. It provides a path for static electricity to move safely to a ground point, preventing static buildup on people or objects. ESD flooring can be made from various materials, including vinyl, epoxy, rubber, or carpeting, each with its own electrical properties and suitability for different environments.

There are two main types of ESD flooring:

1. Conductive Flooring: This type of flooring has a lower electrical resistance, typically less than 1 million Ohms (Ω). It allows for the rapid and direct dissipation of static charges to the ground. Conductive flooring is commonly used in environments where there is a high risk of flammable or explosive materials, as it ensures the quickest discharge of static electricity.

2. Static-Dissipative Flooring: Static-dissipative flooring has a higher electrical resistance, typically in the range of 1 million to 1 billion Ohms (Ω). It controls the flow of static electricity at a slower rate, reducing the risk of sparking or discharges that could damage sensitive electronic devices. Static-dissipative flooring is commonly used in environments where static-sensitive equipment or components are present.

ESD flooring offers several advantages in environments where electrostatic discharge control is crucial. Here are some key advantages of ESD flooring:

1. Electrostatic Discharge Protection: ESD flooring is designed to control and dissipate static charges, preventing electrostatic discharge. It helps to maintain a controlled environment with low static electricity levels, reducing the risk of damage to sensitive electronic components and equipment.

2. Equipment Protection: By minimizing or eliminating electrostatic discharge, ESD flooring safeguards sensitive electronic equipment from potential damage. It can prevent malfunctions, data loss, or complete failure of electronic devices caused by ESD events.

3. Enhanced Safety: ESD flooring improves safety in the workplace by reducing the risk of electrical shocks to personnel. It provides a controlled path for static charges to dissipate safely, minimizing the chances of electrostatic shocks that could cause injury.

4. Consistent Performance: ESD flooring maintains its effectiveness over time, providing a long-term solution for electrostatic discharge control. The materials used in ESD flooring are durable, resistant to wear and tear, and can withstand heavy foot traffic and equipment movement, ensuring reliable performance.

5. Cleanroom Compatibility: ESD flooring is commonly used in cleanrooms and controlled environments where maintaining low particle levels is crucial. Many ESD flooring options are designed to be easy to clean and resistant to chemicals, making them suitable for cleanroom applications.

6. Versatility and Customization: ESD flooring is available in various forms, such as tiles, sheets, or coatings, offering flexibility in design and installation. It can be customized to meet specific requirements, including different levels of conductivity or dissipative properties, color options, and surface textures.

7. Regulatory Compliance: ESD flooring helps organizations comply with industry standards and regulations related to electrostatic discharge control. Depending on the industry and application, there may be specific requirements for ESD protection, and implementing ESD flooring can contribute to meeting those standards.

It’s important to note that the effectiveness of ESD flooring depends on proper installation, maintenance, and the implementation of complementary ESD control measures such as grounding systems, wrist straps, and ESD-safe practices. Consulting with professionals who specialize in ESD control is recommended to ensure optimal performance and compliance with industry requirements.

Requirements for selection ESD flooring products

When selecting ESD (Electrostatic Discharge) flooring products, there are several important criteria to consider. ESD flooring is designed to prevent the buildup and discharge of static electricity, which can be harmful to sensitive electronic components and equipment. Here are some key factors to consider when choosing ESD flooring:

1. Electrical Performance: The primary purpose of ESD flooring is to control static electricity. Look for flooring products that provide consistent and reliable electrical conductivity or resistance within the acceptable range. This is typically measured in Ohms (Ω) and depends on the specific requirements of your environment and the equipment being used.

2. Compliance with Standards: Ensure that the ESD flooring product meets relevant industry standards and guidelines, such as ANSI/ESD S20.20 or IEC 61340-5-1. These standards define the requirements for ESD control programs and provide guidelines for the performance of ESD flooring.

3. Durability and Lifespan: Consider the durability and expected lifespan of the flooring product. ESD flooring should be able to withstand heavy foot traffic, rolling loads, and frequent cleaning without compromising its electrical properties. Look for products with high wear resistance and long-term performance guarantees.

4. Maintenance and Cleanliness: ESD flooring should be easy to clean and maintain to ensure its long-term effectiveness. Look for products that are resistant to chemicals, abrasion, and stains. Smooth, non-porous surfaces are typically easier to clean and maintain compared to textured or porous options.

5. Compatibility with Surrounding Environment: Consider the specific requirements of your facility or environment. For example, if you have a cleanroom or controlled manufacturing area, the ESD flooring should be compatible with the air cleanliness and hygiene standards of the space. In healthcare or laboratories, resistance to chemicals and disinfectants may be crucial.

By considering these selection criteria, you can choose an ESD flooring product that best suits your specific needs and ensures effective static control in your environment. It is recommended to consult with ESD flooring experts or professionals to help you make an informed decision based on your unique requirements.

Neocrete ESD flooring products

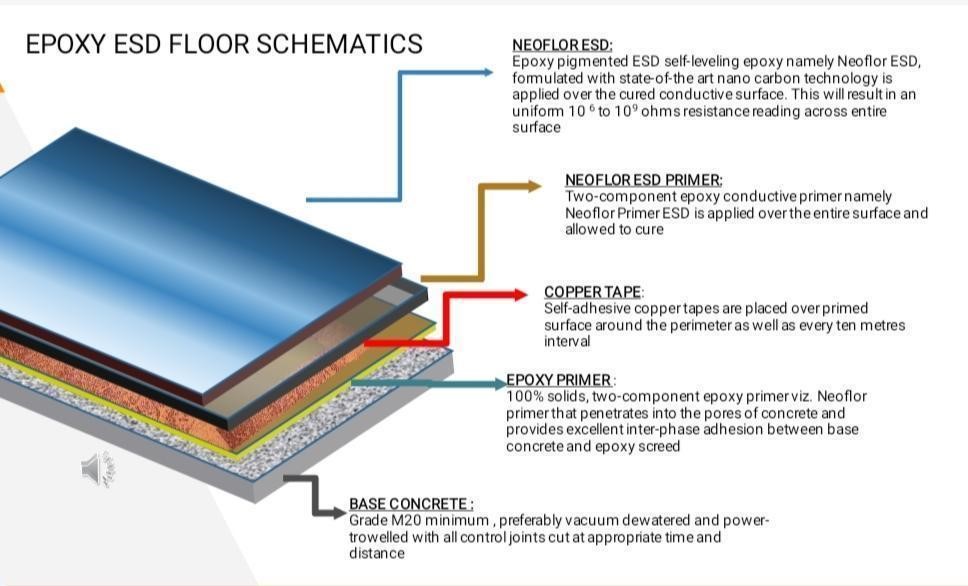

Neocrete Technologies Pvt Ltd has a wide range of specialty ESD coating products to help address the static electricity on various surfaces. Its “Ground-Breaking” ESD coating products are manufactured using carbon nanotube technology which ensures uniform distribution and durability.

ESD flooring product range;

- Neoflor ESD Primer: two-component, solvent-free epoxy primer that needs to be coated prior to the application of Neoflor ESD or Neoflor ESDC 20 Kg unit

- Neoflor ESD: four-component, solvent-free, epoxy self-levelling ESD floor topping that can be designed either as conductive or dissipative surface.

- Neoflor ESDC: two-component, solvent-free, epoxy self-levelling ESD coating that can be designed either as a conductive or dissipative surface.

- Neostatic HDT: PU concrete floor that provides dissipative surface coupled with high abrasion and impact resistance

Application

ESD flooring finds application in various industries and environments where electrostatic discharge control is essential. Here are some common applications of ESD flooring:

1. Electronics Manufacturing: ESD flooring is widely used in electronics manufacturing facilities, including assembly areas, testing areas, and cleanrooms. It helps protect sensitive electronic components and equipment from damage caused by electrostatic discharge, ensuring the production of high-quality electronic products.

2. Server Rooms and Data Centers: ESD flooring is crucial in server rooms and data centers where critical IT infrastructure is housed. It prevents electrostatic discharge that can harm servers, networking equipment, and other sensitive electronic devices, ensuring the reliability and performance of data center operations.

3. Laboratories: Laboratories, particularly those involved in research and development, often deal with sensitive equipment and electronic devices. ESD flooring is used to create a controlled environment that minimizes the risk of electrostatic discharge, ensuring accurate experimental results and preventing damage to delicate instruments.

4. Aerospace and Defense: ESD flooring is employed in the aerospace and defense industries where strict ESD control is necessary. It is used in manufacturing facilities, maintenance and repair areas, and other locations where sensitive electronic systems and components are handled, ensuring the safety and reliability of aerospace and defense equipment.

5. Healthcare Facilities: ESD flooring is used in healthcare facilities, including hospitals and medical device manufacturing areas, to protect electronic medical equipment from electrostatic discharge. It helps prevent disruptions in medical equipment functionality and ensures the accuracy of diagnostic and treatment procedures.

6. Pharmaceutical and Biotechnology: In pharmaceutical and biotechnology environments, where precise measurements and control are essential, ESD flooring is utilized. It helps maintain the integrity of electronic instruments and devices used in research, development, and production processes, ensuring accurate and reliable results.

7. Automotive and Automotive Electronics: ESD flooring is used in automotive manufacturing plants and automotive electronics production facilities to protect electronic components and sensitive automotive systems from electrostatic discharge. It helps maintain the quality and reliability of automotive electronics and electrical systems.

Conclusion

When considering ESD flooring options, it is important to assess the specific needs of the industry and facility. Factors such as the level of electrostatic protection required, the type of environment, installation considerations, and budget should be taken into account. Consulting with ESD flooring experts or specialists can help in selecting the most appropriate flooring solution for the specific application.

If you want ESD flooring products for your facilities, visit- https://www.neocrete.co.in/product/esd-floorings/