Roof welding is the method of using heat to join or seal roofing materials, typically involving thermoplastic membranes or modified bitumen. One of the important aspects of this process lies in selecting the appropriate tools. The correct tools offer precision and control throughout the welding procedure, facilitating accurate seam creation and minimizing the risk of errors. Moreover, they enhance efficiency, streamline the welding process, and reduce the time and effort required for completion.

Different tools used for roof welding

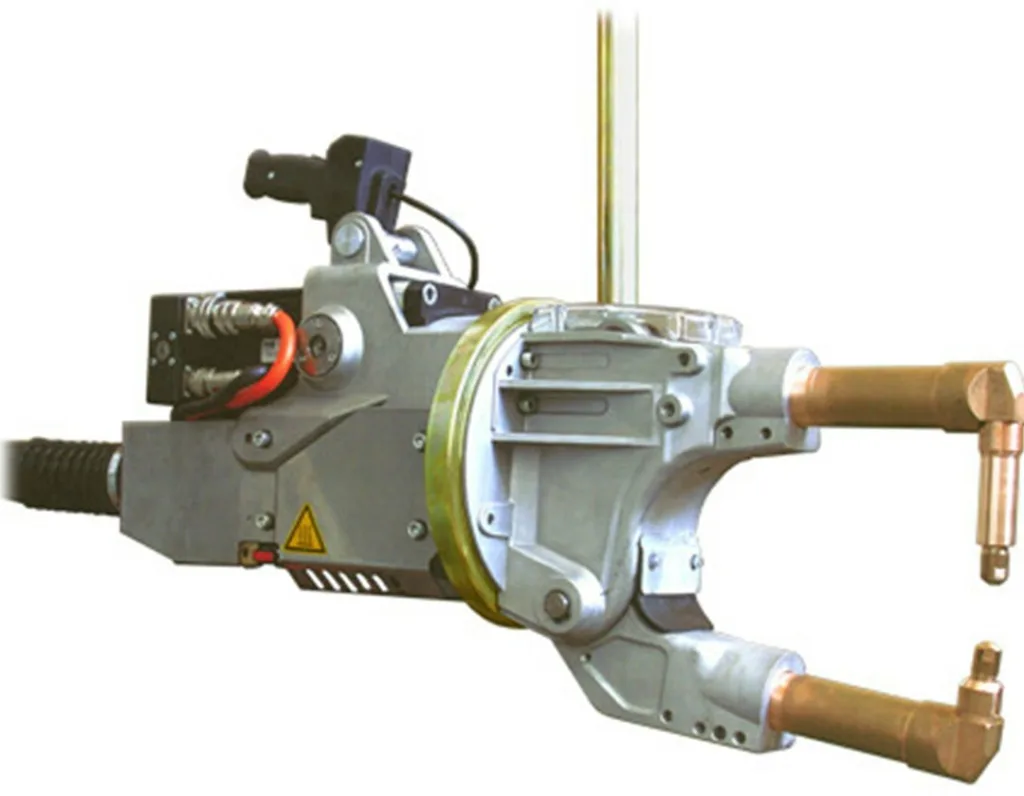

Spot Welding Gun:

A spot welding gun is a handheld device designed for precise welding in PVC applications. It operates by delivering concentrated heat to specific areas, creating localised welds. Typically powered electrically, these guns offer variable temperature control and come with various tip sizes for versatility. Their design allows for quick and accurate welding, making them ideal for joining thin PVC materials or creating specific weld patterns.

Heat Guns:

Heat guns are versatile handheld devices used in PVC welding and roofing. Emitting hot air, they soften or melt PVC materials, offering flexibility in applications such as bending and welding. With adjustable temperature settings and various nozzle attachments, these guns provide control over the heating process. This versatility makes them valuable tools in different stages of PVC roofing projects, allowing for precise temperature adjustments based on the specific requirements of the material being worked on.

Welding Gun:

The welding gun is a handheld tool employed in the PVC welding process, applying heat to join materials effectively. Designed for precision, it is often used with welding rods or filler materials. These guns come equipped with variable temperature settings, allowing for adaptability to different PVC materials. Their ergonomic design and ease of use make them valuable for creating strong and durable welds in roofing applications.

Roller Pressure Tools:

Roller pressure tools are essential for ensuring proper adhesion and bonding in PVC welding seams. These tools consist of rollers that apply even pressure across welded seams, with adjustable settings for different materials. The latest tools feature grooves or patterns to impart specific finishes to seams. Roller pressure tools play a key role in achieving smooth and consistent welds, enhancing the overall durability and performance of the roofing material.

Trimming Tools:

Trimming tools encompass various cutting instruments, including knives and shears, used to achieve a clean and professional finish after PVC welding. These tools are designed for precise trimming of excess material, ensuring the final appearance of the welded seams meets desired standards. With features like depth adjustments and guides, trimming tools contribute to the accuracy of the cutting process. Their role extends beyond functionality to aesthetics, enhancing the overall visual appeal of the roofing material by providing a neat and well-finished appearance to the welded seams.

Roof PVC Welder:

A Roof PVC Welder is a specialized tool designed for welding PVC materials commonly used in roofing applications. These welders are equipped with features tailored to the unique demands of roofing projects, ensuring efficient and durable seams. Typically handheld, they offer precision in welding and are designed to handle the specific characteristics of PVC roofing materials. The advantage of Roof PVC Welders lies in their ability to create secure and watertight seams, contributing to the overall longevity and reliability of the roofing structure.

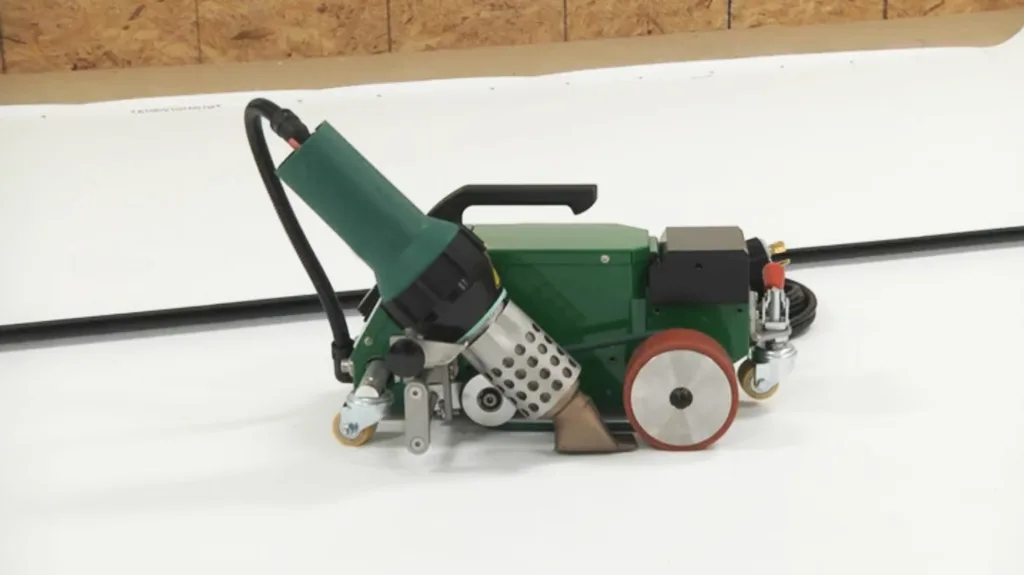

Overlap Hot Air Welder:

An Overlap Hot Air Welder is a type of PVC welding tool that utilizes hot air to join overlapping PVC sheets. This tool is particularly effective in creating seamless connections between adjacent PVC roofing materials. The hot air ensures thorough melting and bonding of the overlapping sections, resulting in robust and leak-resistant seams. The advantage of Overlap Hot Air Welders lies in their ability to produce strong and continuous welds, important for maintaining the integrity of the roof in diverse weather conditions.

Roofing Welder:

A Roofing Welder is a tool specifically designed for welding applications in roofing projects. These welders are optimized to handle the demands of roofing materials, ensuring effective bonding and seam integrity. They may incorporate features such as temperature control, ergonomic design, and compatibility with various PVC roofing materials. The advantage of Roofing Welders lies in their specialization for roofing applications, offering efficiency and durability in creating secure welds for weather-resistant roofs.

Handheld Seam Testers:

Handheld seam testers are devices specifically designed for quality control in PVC welding. They facilitate the checking of welded seams for integrity, typically using a pressurized system to detect leaks or imperfections. Portable and easy to use on-site, these testers play a key role in identifying potential issues in the welds, ensuring that the PVC roofing material meets quality standards. Handheld seam testers contribute to the efficiency of the welding process by allowing for quick and effective testing of seams, providing assurance of the material’s reliability and performance in various conditions.

How to select the right tools for roof welding?

- Understand project requirements, considering PVC material type and project scale.

- Ensure tools compatibility with specific PVC roofing materials.

- Evaluate power source options (electric, pneumatic) based on job site conditions.

- Check for adjustable temperature settings in welding tools for different PVC materials.

- Consider ease of use and ergonomic features for user-friendly handling.

- Look for safety features, including thermal protection and insulation in heat tools.

Conclusion

Roof welding tools play an important role in ensuring the durability and resilience of roofing structures. From efficient seam welding to precise temperature control, these tools contribute to the overall integrity of roofs. As technology continues to advance, staying updated on the latest innovations in roof welding tools becomes essential.