Concrete has been a big boon to the construction industry for about two decades. It has been serving the industry and also has been getting modified based on the changes in functional end requirements. With significant properties of concrete that have contributed to the overall versatility of the structures, it has also been showing a few limitations that are revealed when concrete structures are exposed to those challenges. Parameters and overall performance of concrete have adverse effects on getting exposed to those conditions. This needs to be addressed with a Techno Professional approach. The Gulf sector is surrounded by sea, oil & gas industries, petrochemical complexes and refineries. They pose many challenges to the concrete structures. The paper addresses those conditions and probable repair remedial measures for the sustainability of concrete structures in the Gulf region.

Introduction

The Gulf region presents unique challenges to concrete structures due to its geographical and environmental conditions. Salinity from the sea, high water tables, and atmospheric conditions pose significant threats to the integrity of concrete, necessitating a focused approach to protect and maintain these structures.

Challenges Faced by Concrete Structures in the Gulf

Salinity Effects

Concrete structures in the Gulf encounter significant challenges, primarily stemming from salinity in water, sand, and the atmosphere. The Gulf, surrounded by sea on all sides, experiences pervasive salinity in both water and the air. The heaps of sand in the region are nearly saturated with salinity, comprising predominantly chloride and sulphate salts, among others. The concrete matrix, with its ingredients, struggles to endure continuous exposure to these adverse atmospheric conditions.

The hydration process of concrete is obstructed by this salinity, initiating the deterioration of the concrete matrix. The first parameter impacted by this exposure is the alkalinity of concrete. Concrete, ideally maintaining an alkalinity between 12 and 13 for sustainable performance, begins a declining trend under these conditions. The reduction in alkalinity opens the door for corrosive contaminants to enter the concrete matrix, reaching its core and compromising its integrity.

High Water Table Concerns for Basements

Another formidable challenge faced by concrete structures in the Gulf region is the high water table. Surrounded by deep-sea on all sides, the Gulf countries experience a higher-than-normal groundwater table compared to other regions. This factor poses a significant threat to structures, especially those with basement parking due to space constraints. Basements are vulnerable to water ingress, and the infiltrating water is saline and salty, posing a potential risk to the concrete members.

Some basements also experience the effects of uplift pressure, a phenomenon causing differential movement depending on the pressure exerted by the basement mass. This movement leads to the development of structural cracks, requiring rectification through structural treatment. In certain instances, water ingress within Gulf segment basements tends to rise to elevated floors through capillary action, affecting both the concrete and steel components of the RCC members. The salts in the water react and deteriorate the concrete, leading to corrosion in the reinforcement steel. This not only jeopardizes the overall safety of the structure but also creates cracks along the reinforcement route, providing access for contaminants to damage the concrete member.

Damage Phenomena and Consequences of Challenges

The ensuing discussion delves into the damage phenomena and resulting effects caused by the challenges faced in the Gulf region.

Salty water and sandy environments contain chemicals that react with the cement in the concrete matrix. The initial consequence is the depolarization of cement, leading to a gradual loss of its binding properties. This initiates heterogeneity within the concrete mass, giving rise to porosity and crevices in the matrix. As a result of this process, the stability of the concrete member moves towards an ‘unsafe’ stage.

An additional effect is the generation of efflorescence, visible as a whitish spread over the external surface of the member. It’s crucial to note that this is not merely a cosmetic disorder but signifies structural deterioration.

When salty water and sand reach the reinforcement steel, they create conditions conducive to corrosion potential for the steel bars. The corrosion product of steel requires more volume and lacks space within the confined concrete mass, exerting pressure on the walls of the concrete member. This pressure results in cracks, posing a structural threat to the safety and stability of the entire structure.

Cracks stemming from the differential reaction to uplift pressure caused by the high groundwater table present another area of concern. While the raft foundation of the structure is typically designed to counteract this uplift pressure, structures close to the sea face fluctuations in the groundwater table due to tidal movements. This leads to momentary high upwards thrust, potentially causing weaknesses in the raft of the building, failing to sustain this pressure.

Given the geographical location of the Gulf segment, it will consistently confront these challenges. Therefore, acceptance of these circumstances is imperative, accompanied by the identification and implementation of measures to protect structures exposed to these challenges.

Repair Measures for Mitigation of Deteriorating Concrete Structures in the Gulf

Despite the inherent challenges posed by its geographical location, the Gulf segment must acknowledge and address these issues to protect its structures. Various measures can be implemented to mitigate the effects of deteriorating conditions. Here are some recommendations:

1. Coving Fillet at Junctions

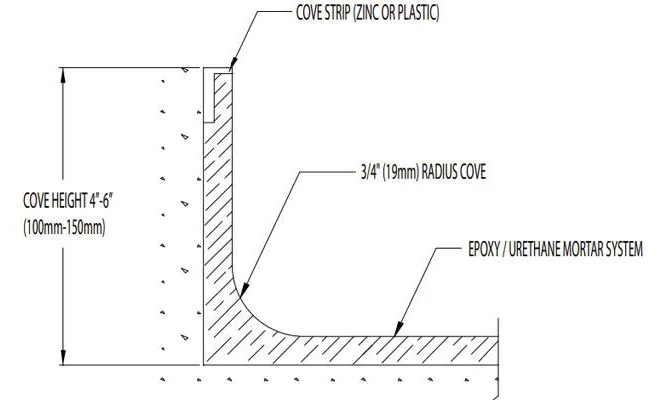

The junctions between vertical and horizontal surfaces are vulnerable spots prone to water ingress. Constructing a coving fillet, preferably in a half-round shape, at these junctions can alleviate stress and prevent the formation of micro-crevices. This proactive approach reinforces the weak points, making them more resilient to external water ingress.

2. Catch Water Channels

Building catch water channels along the entire periphery of the structure is an effective strategy. These channels can intercept ground water exerting pressure from the sides (except from the bottom). By doing so, the sides of the sub-structure are shielded from the impact of the surrounding high water table, offering protection against potential damage.

3. Box Waterproofing for Basements

While box waterproofing for basements is a standard treatment, its effectiveness in preventing external water ingress can vary. This method provides a level of protection, but it may not be foolproof against certain external sub-soil contaminants. Additional measures are needed to fortify the resistance to external water ingress.

4. External Waterproofing at Sub-Base Level

A more robust solution involves external waterproofing at the sub-base level of the structure. Though this approach is implemented in some structures, its resistance to external sub-soil contaminants may not always be sufficient. Strengthening this resistance is crucial for preventing external water ingress effectively.

5. Injection Grouting for Structural Damage Prevention

Injection grouting is a method used to prevent structural damage caused by challenging conditions such as salinity and high water tables. However, this technique is not a standalone solution and necessitates continuous monitoring through inspections and tests. Regular assessments are vital to ensure the structural healthiness of the Gulf’s concrete structures at both sub-soil and elevated levels.

Maintaining the structural health of concrete structures in the Gulf sector demands focused efforts in protection, inspection, and retrofitting. Implementing these measures can contribute to enhancing the resilience and longevity of structures in the unique and challenging Gulf region.

Conclusion

Safeguarding concrete structures in the Gulf against the adverse effects of salinity and high water tables is imperative for their longevity and resilience. By adopting proactive measures such as coving fillets, catch water channels, and robust waterproofing strategies, the Gulf segment can fortify its structures against potential deterioration. The use of injection grouting as a preventive measure underscores the commitment to ongoing monitoring and maintenance. Ultimately, a comprehensive approach to protection, inspection, and retrofitting is essential for ensuring the structural health of these concrete structures in the face of the unique challenges posed by the region’s geographical conditions.

About the author;

Er. Chirag K. Baxi is the Director of Prudent Forensic Consultancy Private Limited and General Manager of K K Retroflex Solutions. He specializes in Corrosion Control Measures for concrete and steel surfaces, Damage assessment with the FORENSIC ENGINEERING approach and Structural rehabilitation of concrete and steel structures in the Industrial environment. He holds a degree in BE (Civil Engineering) and has completed MBA (Construction Management).

The author has invented CONCARE B 14 (which has been granted a patent) that makes concrete structures sustainable even with salty, saline, untreated or even seawater without deterioration in any of the end properties of constructed elements. He has written (two) drafts of IS Codes on the topic of “Carbon brick lining” and “PolyPropylene Glass lining” which are under the final stage of approval at BIS.

About 40 Technical papers on National and International platforms are authored, published and presented by the author. He has been recognized by several Institutes for his significant contribution to the Civil Engineering Industry.