The popularity or the demand for the seamless floor around the world started in 1930’s. But fragrance for seamless reached India in the mid 1980’s and 1990’s it has bought a demand for seamless floors like Epoxy and Polyurethane. The usage of tiles and stones in the industries were slowly fading and monolithic floors have taken its place.

But due to the increased globalization and restructuring the floor coating industry, a shift in the industry trends is observed owing to rapid economic growth.

Moreover, the growth in population in the country is expected to boost the demand for commercial and industrial infrastructure, which in turn is projected to drive the floor coating market.

Modernizing the infrastructure of the existing plants to meet the demands of the modern era was the difficult phase especially the flooring which takes minimum 7 days to 28 days for the 100% curing. This is the period where people are looking for quick curing floor without disturbing much of their production period. So, Methyl Methacrylate is one of the products that will have 100% percent mechanical strength in 1 hour after their application.

Methyl Methacrylate in short called MMA floors have good bonding to existing surfaces like tiles, natural stones, granite, wood, steel, etc for renovation without disturbing the structure and also very good on concrete for new projects.

Choosing the correct floor coating type for your project need is important. One such flooring type is methyl methacrylate [MMA]. This is an acrylic resin and the system consists of a primer, main coat and topcoat to seal the finished floor.

Silikal MMA Flooring Systems

Silikal initially concentrated on screed construction. At the start of the 1960’s Silikal began to develop new, modern synthetic resin-based products for the dynamically growing construction sector; primarily for floor coating and engineering application in trade and industry. They have continued that path with countless research projects to date. For the last few decades, the company has been active across the world creating floors with MMA. Today, their customers can choose from a large number of MMA products and specialties, whether coating, sealant or mortar which are tested to CE, TÜV and AgBB standards.

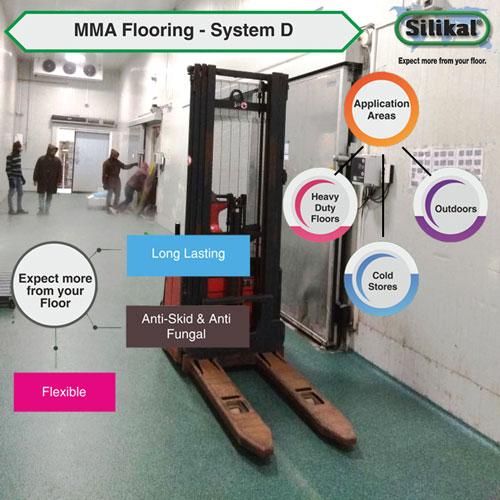

In this series we have focused on Standard coating systems System D of Silikal. Cold stores, heavy-duty and outdoors wherein significant impact stresses are expected, and temperature influences vary sharply, coating materials of SILIKAL® are designed to be impact-resistant.

Silikal System Coating D-Cold rooms, Freezer rooms, Walk In chillers, heavy duty floors and Outdoor.

Floors used in areas like cold rooms, heavy duty floors and Outdoor should have the characteristics of flexibility, load bearing capacity and UV resistant, Silikal has got all this in System D of floor coating application. MMA resins cures quickly that the facility can be back to accepting traffic within 1 hour after application. It is possible to install these floors in temperatures that are below 0 degree Celsius and up to 35 degrees Celsius. Silikal MMA resin-based flooring systems do not degrade when exposed to UV light. They are also resistant to acids and alkaline. Silikal MMA floors are certified under HACCP, LEED and HALAL certified.

Any further queries related to the cold rooms, heavy duty floors and outdoor, kindly write to us directly and we will be glad to assist your flooring solution – Silikal India.