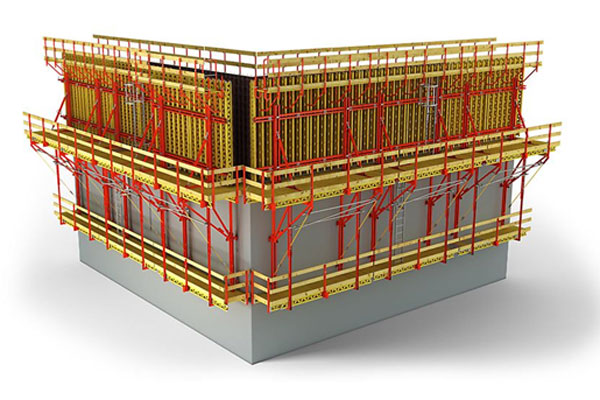

Climbing formwork is a special type of formwork for vertical concrete structures that rises with the building process. It is an effective solution for buildings that are either very repetitive in form or that require a seamless wall structure. It is mostly used in the construction of towers, skyscrapers and other tall vertical structures, it allows the reuse of the same formwork and over and over for identical sections further up the structure. It can also enable very large concrete structures to be constructed in one single pour (which may take days or weeks as the formwork rises with the process), thus creating seamless structures with enhanced strength and visual appearance, as well as reducing construction times and material costs. This formwork type normally does not only contain the formwork itself but also usually provides working space/scaffolds for construction crews. It may also provide areas for machinery and screens for weather protection, up to being fully enclosed while yet staying modular around a changing building structure.

Different types of climbing formwork

There are a large number of different climbing formwork systems, all with their benefits and specifications. You may find that one type of formwork system is better for one project than another. Because of the diversity of formwork systems and what they have to offer, it is always advisable to get the right advice for your particular project.

- Climbing formwork (crane-climbing)– Crane Lifted Climbing System is mainly used in the construction of concrete walls with non-slab, core wall or dam, concrete breast wall, cooling tower, tunnel and underground liner structure, etc. For wall formwork construction, set the main bracket with the anchor firstly, then set other parts. In this type of formwork around the structure is displaced upwards with the help of one or more once the hardening of the concrete has proceeded far enough.

- Climbing formwork (self-climbing)- Self-climbing formwork, sometimes known simply as climbing formwork, is a special type of formwork used for vertical concrete structures. It is particularly useful for structures that have quite a repetitive form or the project requires seamless walls.

Components and Assembly of climbing formwork

In this type of formwork different setups are used depending on the structure, every formwork assembly is unique and can only be designed as per project drawing and requirement.

The main components of climbing formwork are:

- Platforms for concrete workers

- Wall formwork material and pieces

- Lifting beam

- Additional working platform

- Suspension platforms

The assembly process of climbing formwork is as followed;

- Climbing formwork is constructed from steel members

- Concrete form panels are attached to this frame; some of them are supported on rollers

- Once concrete walls are poured, it is released and moved away from the wall

- Use jacks, lift the frame to the next level or to the next area where it will be used

- Once the climbing formwork is in position, the panels are closed

- The next concrete wall is poured

- The cycle continues for three to five days

Advantages of climbing formwork

It is one of the best choices for work on the heights and getting them done in optimised time, maintaining sync during climbing, concrete pouring and de-shuttering that too in the safest way possible. Given below are its advantages.

- It facilitates the construction of both vertical and horizontal parts of the building concurrently

- High-quality surface finishes can be achieved

- Faster construction speed

- Requires less labor to set up the formwork

- It can sustain high wind

- A higher safety of labour during the setting and removal process

- The climbing formwork system does not require any additional supports

- Can be used in inclined angles

- Easy to clean and reuse with little waste generated compared to traditional systems

- It does not need additional supports to the formwork

- Reduces the use of scaffolding and temporary work platforms

- Customization is possible for any type of complex wall geometries

- Large shafts can be constructed by climbing formwork system without using a crane

- Long lengths can be obtained combining different sections for each particular project

- Minimize the usage of scaffolding and temp work platforms

Applications of climbing formwork

The process of this type of formwork includes elevation of the mast and the climbing bracket-formwork-set along the wall surface. It can be applied in various places such as;

- High rises and skyscrapers

- Bridge piers and pylons

- Power stations

- Barrages

- Dam

- Cooling towers

- Airport control towers

- Silos

Image- Peri India, doka.com/in