A drilling rig is a robust and specialized machine designed to create holes in the ground for various purposes, such as laying foundations, installing utilities, or extracting geological samples. It typically comprises a drill bit attached to a drill string, which transmits rotational force and drilling fluid from the surface. Supported by a sturdy mast, the rig is powered by an engine or motor, driving the drilling process while a mud system circulates drilling fluid to cool and lubricate the bit and carry cuttings to the surface. Equipped with a control panel for monitoring and adjustment, along with essential safety features, these rigs offer versatility and efficiency in creating holes of varying sizes and depths across different terrains, facilitating the construction process with precision and reliability.

Where are drilling rigs used?

Drilling rigs are used in construction projects in various locations and for diverse purposes, including:

1. Foundation Construction: Drilling rigs are utilized to bore holes for foundations of buildings, bridges, dams, and other structures. They create stable support systems by drilling into the bedrock or suitable soil layers.

2. Piling Installation: Drilling rigs are employed to install piles, which are long, slender columns driven into the ground to provide structural support for foundations or to stabilize slopes and embankments.

3. Excavation: In certain construction projects, drilling rigs are used for excavation purposes, such as creating boreholes for soil investigation, environmental assessments, or mineral exploration.

4. Tunneling: Drilling rigs are crucial for tunnel construction, where they bore through various geological formations to create tunnels for transportation systems, utilities, or underground storage facilities.

5. Utility Installation: Drilling rigs play a vital role in installing underground utilities like water pipes, sewer lines, and electrical conduits. They bore holes for utility placement without disturbing the surface or existing structures.

6. Retaining Wall Construction: Drilling rigs assist in building retaining walls by drilling holes for anchor rods or tiebacks, which provide stability and prevent soil erosion or slope failure.

Advantages of drilling rigs

- Efficient and precise hole creation

- Versatile applications in construction

- Minimized environmental impact

- Enhanced safety features

- Improved productivity onsite

- Reduced labour requirements

- Ability to drill in various terrains

- Capable of drilling at different angles

- Enables access to deeper depths

- Facilitates exploration for resources

- Supports large scale construction projects

- Minimal disruption to surrounding structures

- Can operate in remote or inaccessible areas

- Offers customization for specific project needs

- Enables consistent hole diameter and depth

- Supports both small and large diameter drilling requirements

- Decreases reliance on manual excavation methods

- Enhances efficiency in challenging geological conditions

- Reduces the need for additional equipment for excavation tasks

- Enables precise placement of foundation elements

- Facilitates the installation of underground infrastructure

Types of drilling rigs

1. Truck-mounted drilling rigs:

Truck-mounted drilling rigs offer excellent mobility and flexibility, as they can be easily transported to different construction sites using standard roadways. Their compact design makes them ideal for projects where space is limited or access is restricted. These rigs are versatile, capable of performing various drilling tasks such as foundation installation, geotechnical investigations, and water well drilling. Additionally, they typically have lower operating costs compared to larger drilling rigs, making them a cost-effective option for small to medium-sized construction projects. However, their drilling depth and capabilities may be limited compared to larger rigs, making them more suitable for shallow to medium-depth drilling applications.

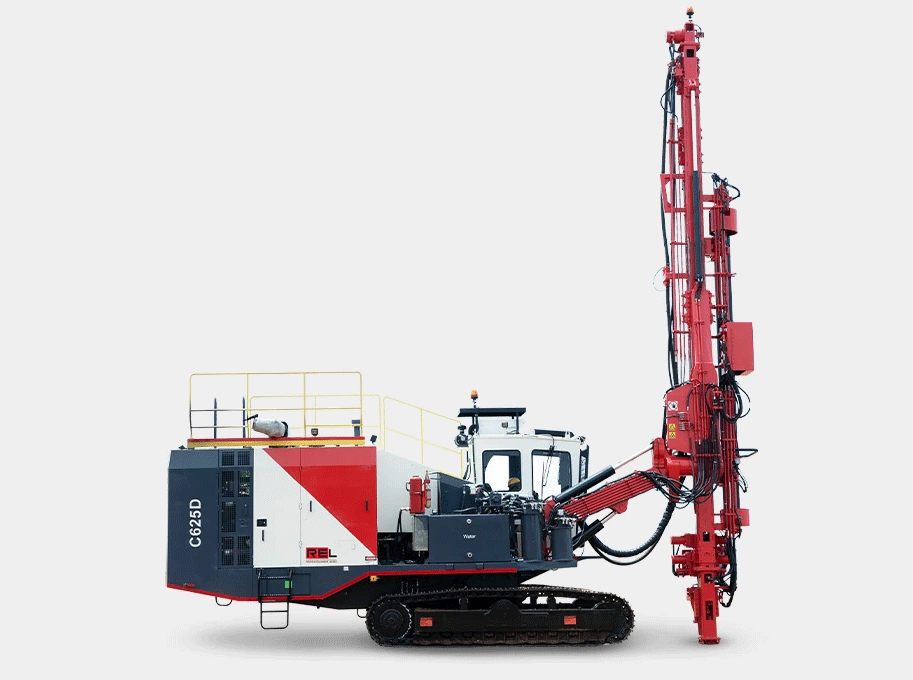

2. Crawler-mounted drilling rigs:

Crawler-mounted drilling rigs are designed for stability and maneuverability in challenging terrains, thanks to their tracks that distribute weight evenly and provide traction on uneven surfaces. This feature makes them well-suited for construction projects in remote or inaccessible areas where conventional vehicles may struggle to navigate. These rigs offer enhanced versatility, allowing them to tackle a wide range of drilling tasks, from soil stabilization and slope reinforcement to foundation drilling in difficult ground conditions. Additionally, their ability to traverse rough terrain minimizes the need for site preparation, saving time and resources. However, crawler-mounted rigs may have higher initial costs and require more maintenance due to their complex track systems, which should be considered when selecting equipment for construction projects.

3. Rotary drilling rigs:

Rotary drilling rigs are equipped with a rotary drilling mechanism that efficiently bores holes in soil, rock, or concrete. One of their key advantages is versatility, as they can be adapted to various drilling methods and can handle a wide range of construction applications. These rigs are capable of drilling to considerable depths, making them suitable for projects requiring deep foundation piling or borehole drilling for utilities. They also offer high drilling efficiency, allowing for rapid progress on construction sites. Additionally, rotary drilling rigs can be equipped with specialized attachments for specific tasks, such as rock coring or soil sampling, further enhancing their versatility and utility in construction projects.

4. Hydraulic drilling rigs:

Hydraulic drilling rigs are powered by hydraulic systems, offering high efficiency and flexibility for drilling in different soil and rock types. Their hydraulic drives provide precise control over drilling operations, allowing for optimal performance and productivity on construction sites. These rigs are often equipped with advanced features such as automatic rod handling systems and real-time monitoring capabilities, enhancing safety and reducing downtime. Hydraulic drilling rigs excel in projects requiring deep drilling or directional drilling capabilities, thanks to their powerful hydraulic drives and customizable drilling parameters. Moreover, their compact design and ease of operation make them suitable for various construction applications, from foundation piling to environmental remediation.

5. Auger drilling rigs:

Auger drilling rigs are specifically designed for excavating soil and creating holes using rotating auger attachments. One of their primary advantages is speed, as they can quickly bore holes for shallow foundations, fence posts, or utility poles. These rigs are versatile and cost-effective, making them suitable for construction projects requiring rapid and efficient drilling of shallow boreholes. Auger drilling rigs come in various sizes and configurations, allowing for customization based on project requirements. Additionally, they are relatively simple to operate and maintain, making them accessible to a wide range of construction professionals.

6. Directional drilling rigs:

Directional drilling rigs are equipped with specialized equipment that allows for drilling boreholes at angles or curves. Their key advantage lies in their ability to navigate around obstacles or reach specific targets underground with precision. These rigs are commonly used in construction projects requiring the installation of utilities beneath existing structures or in congested areas where traditional drilling methods are impractical. Directional drilling rigs offer reduced surface disruption compared to conventional drilling methods, minimizing the impact on surrounding infrastructure and the environment. Additionally, they provide flexibility in design and layout, allowing for more efficient use of space and resources on construction sites.

The demand of drilling rig in India

The demand for drilling rigs in India is propelled by the country’s robust infrastructure development initiatives and rapid urbanization. With a burgeoning population and increasing urban migration, there’s a pressing need for construction of residential, commercial, and industrial spaces, all of which require drilling rigs for foundation piling, soil investigation, and utility installation. It demand is propelled by;

- Robust infrastructure development initiatives

- Rapid urbanization and population growth

- Construction of residential, commercial, and industrial facilities

- Need for foundation piling, soil investigation, and utility installation

- Focus on enhancing transportation networks (roads, bridges, airports)

- Exploration of energy resources exploration and extraction efforts

Conclusion

Drilling rigs play an important role in construction projects, offering efficiency, precision, and versatility across various applications. From foundation piling to soil investigation and utility installation, these machines are indispensable for creating holes in the ground with accuracy and speed. Their ability to navigate challenging terrains, reach significant depths, and adapt to different drilling methods makes them essential assets in the construction industry. As infrastructure development, urbanization, and energy exploration continue to drive demand, drilling rigs will remain integral to meeting the construction needs of growing economies like India. With ongoing technological advancements and innovation, these rigs will continue to evolve, ensuring the efficient and sustainable development of infrastructure.

Image Source: klruniversal.com, prdrigs.com, reldrill.com