Concrete is an integral part of any construction and infrastructure projects due to its durability. Even though concrete is durable, being brittle when subjected to tensile stress, cracks occur. The cracks are formed due to changes in temperature, humidity, wind & corrosion of steel bars, thermal shrinkage, swelling etc. This can be addressed by Steel Fibre Reinforced Concrete (SFRC). SFRC is a heterogeneous structural material consisting of Portland cement, aggregate, and steel fibres. When concrete is reinforced with steel fibre it can improve concrete,’ ductility, high shrinkage cracking, low durability, etc. Steel fibre reinforced concrete. They also lessen the permeability of concrete and therefore reduce the flow of water.

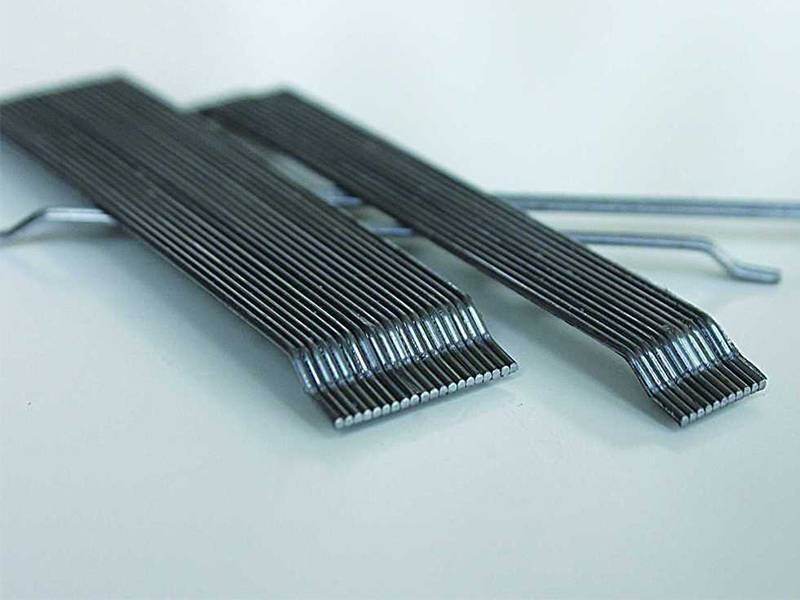

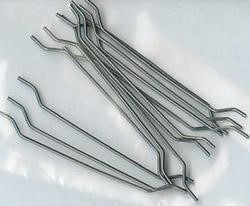

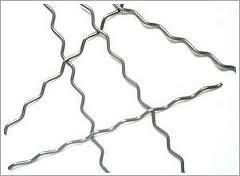

The use of Steel Fiber Reinforced Concrete (SFRC) has received a tremendous impulse because of its flexibility in the use of high-end structural applications. The right product selection from an experienced manufacturer is important for the project, STEWOLS INDIA (P) LTD is the pioneer and largest manufacturer and supplier of Steel Fibres in India and across the globe. The company’s SHAKTIMAN® Steel Fibres are available as Hooked End, Round Crimped and Flat shaped Steel Fibres of various diameters & lengths depending on the requirements of aspect ratio.

SHAKTIMAN® Steel Fibre Advantages;

The unique feature of SHAKTIMAN® Steel Fibres is its 3-dimensional reinforcements as compared to the 2-dimensional reinforcements of conventional steel reinforcement. The 3-dimensional reinforcements increase the tensile strength of the concrete at both the initial and ultimate crack under flexural loading. It can control even the tiniest of cracks and provide increased load-bearing capacity. It reduces repair and maintenance expenses by offering higher fatigue resistance.The product also minimises deformation while maximising durability.

Advantages;

- Flexural strain capacity is enhanced

- Adds ductility to concrete

- Provides joint stability

- Reduces material consumption & saves cost

- Faster completion of the project

- More homogenous mix with concrete

- Controls cracks and provides post crack ductility

- Allow narrow joint width

- Faique and impact resistance

- Shear load transfer

- Increases spalling resistance

- Reduced absorption of water, chemicals, etc.

- Lesser wastage

SHAKTIMAN® Steel Fibre Applications;

Shotcreting

Shotcrete is the method for applying concrete projects in vertical, overhead or underground surface. Shotcreting using steel fibres is being successfully used through either a dry- or wet-mix process in the construction of Domes, Ground Level Storage Tanks, Caverns, Tunnel Linings, Mines, Rock Slope Stabilisation and repair and retrofitting of deteriorated surfaces and concrete. Steel fibre reinforced shotcrete is substantially superior in toughness index and impact strength compared to plain concrete or mesh-reinforced shotcrete. The impact made by the application sets the strength of the concrete to higher flexural strength. SHAKTIMAN® Steel Fibre is used to control rebound and plastic shrinkage and toughness post-crack load capacity.

Advantages;

- Superior in toughness index and impact strength compared to plain concrete or mesh-reinforced shotcrete.

- Improves the crack resistance (or ductility) capacity of the concrete

- Helps in sustaining and redistributing load actions after cracking

- Optimises sprayed lining thickness

Tunnel linings

Tunnel linings using SHAKTIMAN® Steel Fibre

SHAKTIMAN® Steel Fibre is manufactured for the reinforcement of tunnel linings. They are made of prime-quality hard-drawn steel wire to ensure high tensile strength at extremely close tolerances. They come with hooked ends, they deliver optimum anchorage. The product prevents wear, spalling at edges, and chipping of corners, Steel fibre reinforced concrete to be used in the tunnel’s final lining is cast or pumped directly inside the formworks. It can be used in the tunnel lining or tensile and flexural stresses in the concrete.

Advantages

- Reduces shrinkage cracking

- Increases shear resistance

- Improves safety: it doesn’t require man labour for the welded mesh reinforcement and reduces the risk of unexpected collapse or failure of the vault

- Reduces permeability

- Reduces rebound

- Reduces tunnel lining construction time

Bridge and Overlays

Steel Fibres have been optimally and successfully used in various projects worldwide for bridges & overlays. SHAKTIMAN® Steel Fibre is used in bridges due to its highly compact cementitious matrix, the absence of capillary pores, and the mandatory use of fibre reinforcement in constructive applications to ensure non-brittleness failure. Lightweight decks made of SFRC in composite bridges are an alternative to conventional steel orthotropic decks, which are known to suffer fatigue degradation, and can extend the range of applications of steel-concrete composite bridges which nowadays are effectively used for bridge spans. It also reduces erection cost and construction time. The product also provides high compression strength and low creep coefficient.

The product is used in overlays to increase the load-bearing capacity of the existing structure for improving the surface finish and rehabilitation or resistance to abrasion. To place an overlay over an existing slab that is structurally durable, levelled and clean or undamaged, a bonded overlay is recommended. If there is a particularly significant increase in the carrying of slab load capacity, an unbonded overlay can be used.

Roads

Steel fibre when reinforced with concrete provides higher tensile, bending, cracking & wear resistance for road. SHAKTIMAN® Steel Fibre increases toughness and extends the life of the road pavement. It enables the surface layer thinning, and contraction joint spacing to increase and improve the use of road performance, extend the road life, but also to save costs and shorten the construction period.

Advantages

- Good Riding Quality

- Good Abrasion Resistance

- Can withstand extremes of weather

- Exclusion of water

- Skid Resistant

- Can be used in areas where soils have poor engineering properties

- Design Precision

- Availability of Binder

- Reflective Characteristics

Precast structures

Steel Fibres are an excellent additive for precast structures which are widely and universally accepted due to their strength, and preciseness. It is used in architectural panels, tilt-up construction, walls, manhole covers, fencing, septic tanks, grease trap structures etc. It provides colour and texture options, ease of installation, consistent quality, modularity and ease of maintenance.

Dams and canal linings

SHAKTIMAN® Steel Fibre Reinforced Concrete is used for repairing dams and canals. Together with shotcrete, SFRC is a secured solution against unstable slopes, landslides, and road embankments. It prevents the growth of vegetation and rocky strata removal and seepage reduction.

Flooring

For flooring applications, steel fibre is used for control cracking, providing optimised thickness and durability for industrial floors. The fatigue, impact and flexural strength are significantly improved when steel fibres are added to the concrete mix.

Other applications;

- Container terminal

- Runways and Airport Hangers

- Basketball courts

- Railway platforms

- Parking lots etc.

SHAKTIMAN® Steel Fibres significantly increase the impact resistance of concrete and the improvements are greater at higher volume fractions.

About STEWOLS INDIA (P) LTD

Established in 1953 and headquartered in Nagpur, Maharashtra, the company is the leading manufacturer and supplier of SHAKTIMAN® Steel Fibres in India. The company is ISO 9001:2015 certified and well equipped with adequately skilled staff to carry out R & D with the latest testing equipment. They supply products to a wide range of private and government infrastructure projects, including hydel power plants, tunnels, roads, bridges, and factory floorings.

There are numerous projects constructed by using SHAKTIMAN® Steel Fibre for Heavy Duty Truck loading, Floorings, Road, Tunnels and Shotcreting projects, etc. all over the country. Their clientele includes Larsen & Toubro (L&T), Afcons Infrastructure Ltd., Simplex Infrastructures Ltd., Jaiprakash Associates (Jaypee Group), Indian Oil Corporation Ltd (IOCL), NTPC LTD etc. The company also caters to a number of clients abroad, particularly in Europe, East Africa, Asia, Australia, and Central America.

For more details, visit- https://stewols.com/