The use of concrete block making machines in construction has been increasing over the years as the use of concrete blocks have greatly increased. Blocks offer multiple advantages economically, in terms of constructive performance, as well as in build quality and versatility. The Indian concrete block manufacturing market is driven by a rising focus on infrastructure and growing investments in commercial and residential construction. The emergence of eco-friendly building materials are expected to fuel market growth during the forecast period. In the concrete block-making machines market, large-scale players are collaborating with small-scale players to gain inorganic growth in the concrete block making machines market. In addition, manufacturers are also focusing on producing automatic interlock block making machines that can produce all types of blocks, bricks and pavers with the option of changing the moulds.

The modern automatic block making machines are innovated so that they can reduce energy usage. This helps reduce the cost and increase the overall profit. The efficient and fast production line of these machines adds to reducing the per-unit cost of the blocks. Block Machine models are now designed with state-of-the-art engineering technology, to produce a wide range of concrete products like Solid/Hollow Block, Interlock Pavers and Kerb Stones at quicker cycles. Concrete block machines can be greatly utilised by new and small-scale entrepreneurs. The goal of a starting entrepreneur is to balance cost-effectiveness with productivity. you can attain that with the modern range of concrete block making machines. The latest models can be installed in a small place and you can start a small-scale business with limited resources. Different ranges of products can be produced from the same machine with a simple and fast mold change, keeping costs down and prices competitive.

There are different types of models of block-making machines with different production capacities. Different types of blocks such as solid blocks and hollow blocks are used in different applications. So it is important to know what type of machine is more suitable for your needs. Different types of block making machine models are available.

Types of Concrete Block Making Machine Models

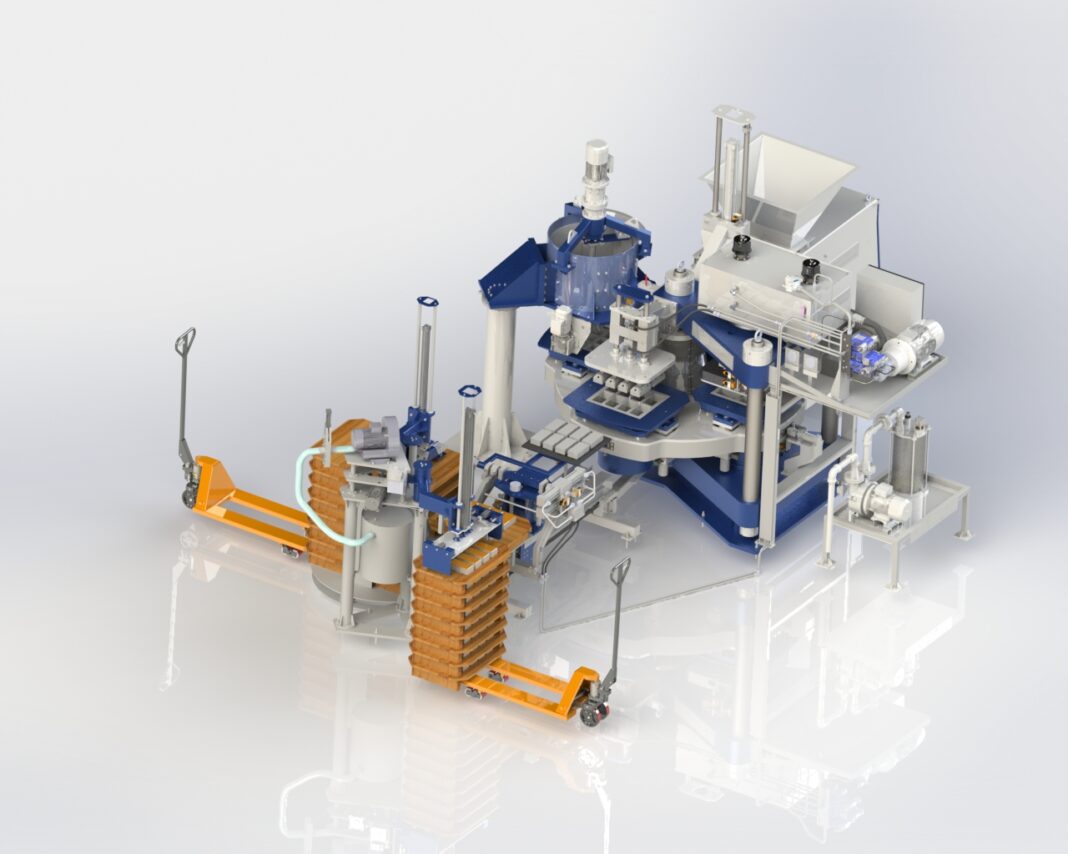

Automatic concrete block making machine

Automatic Concrete Block Making models are manufactured with vibro compaction Technology having robust frame structure with improved design made up of heavy steel with main cylinder The latest models also provide close-grain structure to the block which makes the block highly rigid, vibration resistant and high strength. Whether you’re producing bricks, pavers, coves, slabs, retaining wall and specialty products, or standard concrete blocks, all shapes, textures and colours that you want can be produced from a single production line. The machine can handle all four portions of the concrete block-making process automatically.

Semi-Automatic Concrete Block Making Machine

The latest concrete block Machine can operate semi-automatically with the control of the operator. It comes with PLC control.By changing moulds all kinds of pavers, stone , curbs, block and precast concrete elements such as grass pavers series can be produced serially. Machines can produce the insulated block upon demand. Pallet carriage carts are used to carry the new products that come out of the machine, to the drying area.

Concrete Paver Block Making Machine

A concrete paver block machine is being used in the construction industry to manufacture high-quality paver blocks. Concrete blocks are used in almost every construction project due to their strength and durability. These machines offer various benefits over the conventional block making methods. The concrete paver block making machine can manufacture hundreds of blocks every day without any chance of error or mistake. This increases the production capacity of manufacturers and helps them complete every order on time. Latest models produce high-quality paver blocks and designer tiles. In the production of this, highly flowing colour pigments along with grey are poured into the rubber moulds & solidified in Vibro forming vibrating tables. These machines are manufactured by making use of optimum grade components with the help of modular machines in compliance with set industry norms. Concrete paver Block Machine produces paver blocks, solid blocks, hollow blocks. All blocks size can be designed by your requirement. There are manual and semi-automatic type.

Concrete Solid Block Making Machine

Solid block making machine is the equipment to produce solid blocks, and it is universally used in the building constructions. Latest concrete solid block making machine comes with an egg laying type Hydraulic Press Type. Any type of concrete block can be produced with consistent quality by fixing different types of concrete mould and ram in the machine.The solid block machine produces the bricks without burning, and it doesn’t exhaust the harmful gas to pollute the air. The bricks are made from the slag, construction waste, limestone, which saves the resource and protects the environment.

Concrete Hollow Block Making Machine

Hollow machine that produces hollow blocks using pressure and vibration. The latest models can produce hollow concrete blocks without pallets but molds are limited in capacity and shape as well. Concrete Hollow Block Making Machine has moulds in the shape of hollow blocks, and when the mortar is poured inside these molds, the machine uses vibration and hydraulic force to press the mortar into the molds. Any type of concrete block can be produced with consistent quality by fixing different types of concrete mould and ram into the machine. Our new spares are readily available to replace the interchangeable wearing parts.

Conclusion

Concrete blocks are required in a wide variety of industrial, commercial and infrastructural usages. Since they are available in different sizes, designs and patterns; architects and engineers use them for construction projects. A Concrete Block Making Machine, therefore, is essential nowadays. Increase in the number of government construction projects, along with an increase in the number of multi-storey buildings is projected to boost the demand for concrete block making machines. Moreover, growing public awareness pertaining to the usage of lightweight construction blocks and a rapid boom in the construction of commercial building for malls, offices and others is expected to ensure healthy growth in the demand for concrete block making machines.Furthermore, the beneficial features of concrete block making machines, i.e. optimal performance, reduced errors, and compact design, are also projected to make the adoption of concrete block making machines more lucrative for customers.

Image Source: brickwell.in, qgreentech.com, armixmachinery.com