Worldwide industrial and household food waste amounts to hundreds of billion pounds per year, a large proportion comprises edible scraps, like fruit and vegetable peels. Researchers across the globe have been searching for new ways to recycle these organic materials into useful products. Companies across the globe are focusing on new technologies to reduce food waste and cut costs. In this regard, Material scientists from Tokyo University have developed a novel process for making cement entirely using food waste.

Method To Turn Food Waste into Cement

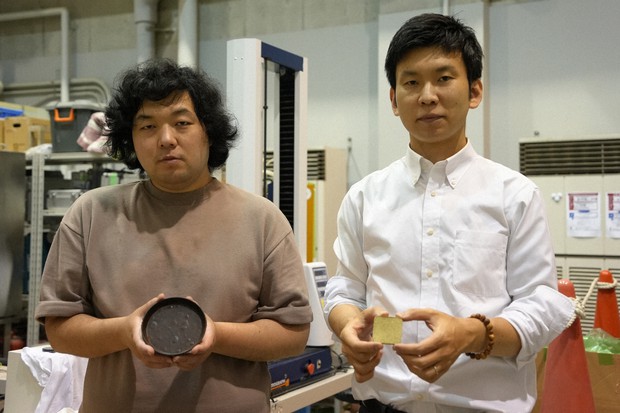

Tokyo University researchers Kota Machida and Yuya Sakai have developed a method that turns food waste such as cabbage leaves, and orange peels into potentially edible and biodegradable cement that can be used for constructing homes. It’s the world’s first process for making cement entirely from food waste. The researchers say the tensile, or bending, strength of their product is nearly quadruple that of ordinary concrete. The edible concrete is made out of substances as diverse as orange peel, coffee grounds, tea leaves, onions, pumpkin, banana peel etc. The humble cabbage was the most impressive of all, forming a material even stronger than conventional concrete.

According to researchers, the tensile strength of the product is almost four times stronger than regular cement. Researchers commenced their research on the concrete by subjecting pulverised wood particles to heat compression. They then used simple mixers and compressors to conduct the three-step process of drying, pulverisation and compression.and then replicated the process with food waste. The earlier process of mixing plastics to food waste was followed to avoid materials from sticking together and after months of trial and error process it was noticed they could easily get the cement to fuse simply by adjusting the temperature ..

The main challenge in the process is that each kind of waste has its own temperature sweet spot. Other experiments for the application of food waste in construction involve using ground coffee or biowaste ashes as filler in regular concrete. And finally, they were successful in producing cement using tea leaves, orange and onion peels, coffee grounds etc.

Sakai and Machida say they have successfully produced cement using tea leaves, orange and onion peels, coffee grounds, Chinese cabbage, and even lunchbox leftovers. They’ve adjusted flavours with different spices and found the colours, scent and taste of the cement can be also quite appealing. For making the cement waterproof and protection against rodents/ pests it is coated with Japense lacquer.To make the cement waterproof and protect it from being eaten by rodents and other pests, it is coated with Japanese lacquer.

The researcher’s ultimate hope is that this cement replaces plastic and cement products, which have worse environmental impacts.