Insulation of material is essential for creating barriers inside of your building and different temperatures outside to prevent heat or sound from being transmitted Insulation serves several important purposes in steel buildings. It addresses two important purposes, stabilising the structure’s interior temperature and preventing moisture from entering or condensing between the outside and inside walls. In addition to keeping the building comfortable, you should also insulate a steel building to prevent moisture from entering the structure through condensation. When it comes to insulating a steel building, insulation is typically installed above the framing, providing more continuous protection. The placement here prevents heat and moisture transfer between the framing, exterior roof, and wall panels. There are many types of insulation available on the market, but depending on your local energy codes and the intended use of your structure, you may be forced to use a particular form of insulation.

Considerations When Selecting Your Steel Building Insulation

When selecting your insulation, look for the following features:

- A high R-value, or thermal break. [R-value indicates the amount of heat flow through an insulation product. The higher the R-value number, the greater is the resistance to heat transference.]

- Condensation elimination.

- Humidity resistant.

- Easy to install.

- Energy efficiency

- Liner panels

- Permeability

- Workability

Advantages of Insulating A Steel Building

- Reduce Condensation

- Manage Temperature

- Absorb sound

- Save on Energy

- High R-value (thermal break)

- Vapour barrier

- Easy installation

Types of Insulation Materials

Different types of materials are used to insulate steel buildings. Each material differs in its function and cost. Insulation for a steel building is selected by comparing the material with the shape, size, location, and purpose of the steel building. Each of them is discussed below.

Reflective Foil

Reflective foil is a radiant barrier that has a thin layer of reflective foil on one or both sides and is designed to reflect heat. Foil insulation can take any one of several forms. Most commonly, it’s supplied as sheets used for sarking, laminated onto plasterboard or expanded polystyrene. It is ideal for hot weather and is mostly used on roofs and walls. It’s designed to reflect heat radiation, but also comes combined with bulk insulation materials like rock wool batts, glass wool batts, loose fill cellulose etc.

Fiberglass Blanket

This is the most common type of material used for steel building insulation due to its low cost and ease of installation. Fiberglass blanket insulation has the added benefits of being both fire and sound resistant. The insulation is outfitted with a vapour retarder and tested for fire safety. The vapour retarder acts as a finish on most metal building ceilings, and because of that, the outward-facing side is white for better light reflectivity in your structure.

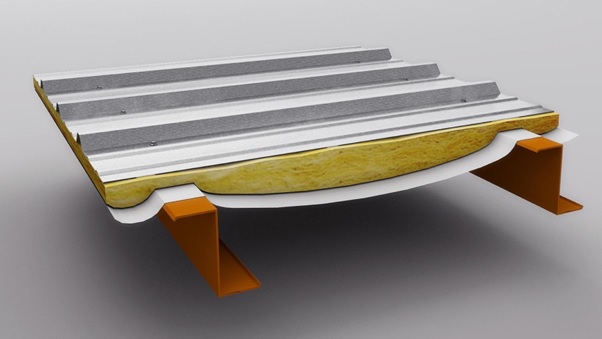

Insulated metal panel

Insulated metal panels are exterior wall or roof panels made of steel skin and an insulating foam core. Insulated metal panels are installed as a single element allowing for faster building completion in almost any kind of weather without risk to system integrity, as opposed to multiple installation steps for other insulated wall and roof systems. The lightweight wall and roof panels are available in a wide range of long-lasting finishes and colours. When combined with the inherent benefits of metal facings, insulated metal panels require less maintenance than other exterior systems and meet the most demanding performance requirements.

Foam board

Foam board materials are used for rigid insulation materials that function by trapping air in individual cells of the foam. It is thermally efficient, vapour retardant and offers dimensional stability. It can be applied both inside and outside your structure and can be finished with various treatments to fit your desired appearance. Foam board insulation is a great alternative to the very common fiberglass batt insulation that is in most of our homes. It has a higher R-Value per inch of thickness, it’s resistant to moisture and is easy to work with.

Spray-on Cellulose

Spray-on cellulose is a paper product with fire-retardant properties. It should only be installed by a skilled and experienced applicator. It increases the benefits of being low cost and successfully absorbing noise.

Conclusion

Today’s steel buildings are energy efficient by design, engineering and construction. Choosing the right insulation material can have a major impact on reducing energy consumption and structural integrity. The insulation systems can make all the difference when it comes to saving money and prolonging a structure’s lifespan. When looking at how to insulate a steel building keep the above-discussed types of insulation in mind: If you’re considering insulating your metal building, you need a team of experts who can help you choose the right material according to the local building requirements.

Analysis of steel building insulation

Considerations When Selecting Your Steel Building Insulation

Advantages of Insulating A Steel Building